Ghetto

Bob it!

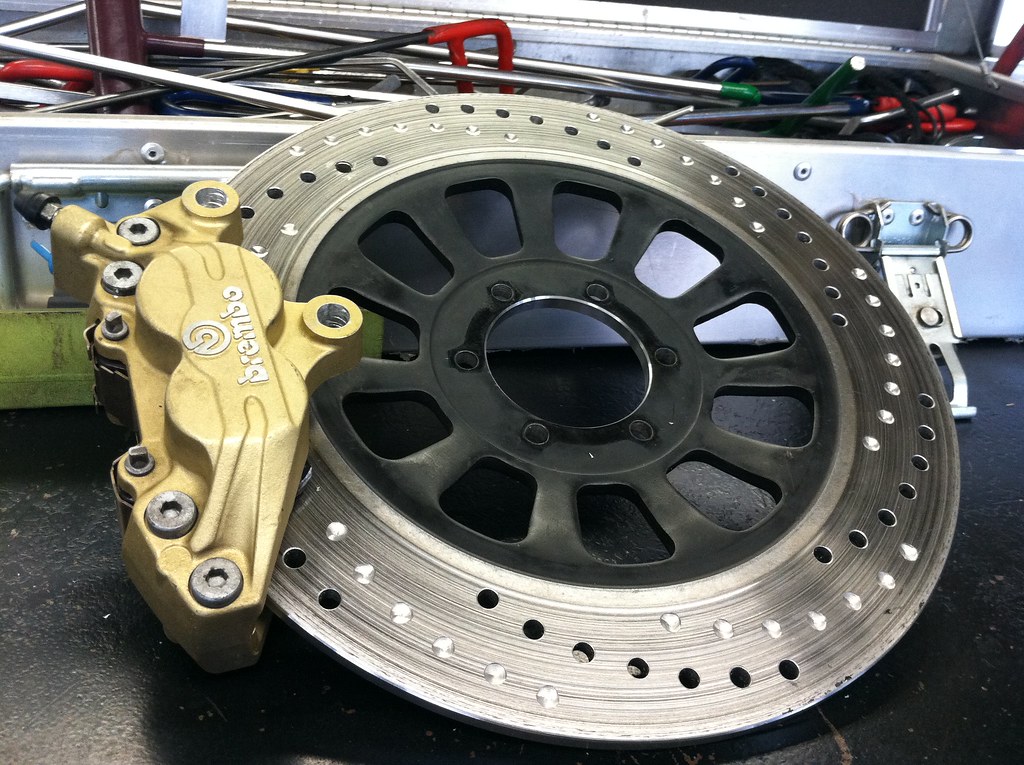

Looks pretty sweet. I am slackin.

the rear wheel is smaller racerdave you are correct

h3llb3nt1 ,

Have You bent those locking tabs over yet?

h3llb3nt1 ,Thats cool a hell! I didn't understand what You ment untill now That I see Your rotor!

I would have liked to have one like it.The next one I'll do that

Have You bent those locking tabs over yet?

10-4 I see what You mean. ThanksCarbon, on your next rotor, I would add one more hole on the outer edge and delete the innermost one.

Used pretty much the same method. I used the depth gauge on my drill press to make the dimples.....

Untitled by Matt Francosky, on Flickr

p!nK