Vacation. Figured I could take two weeks while waiting for my next parts delivery from USA.Nice here but Hanoi still makes me a little nervous..

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 60th birthday present

- Thread starter Mailman

- Start date

-

- Tags

- 1977 xs 650d chain and sprockets clutch pushrod seal cranckcase seal new front master cylinder pamco e-advance pamco ultimate high output ignition rebuild brake caliper rebuild brakes rebuilt carburetors replace clutch solid state rectifier stainless steel braid front brake line starter gear fix steering head bearings vr-115 regulator

Yeah, I can see that.....Vacation. Figured I could take two weeks while waiting for my next parts delivery from USA.Nice here but Hanoi still makes me a little nervous..

Vacation. Figured I could take two weeks while waiting for my next parts delivery from USA.Nice here but Hanoi still makes me a little nervous..

Why nervous David.....were you once in the Hanoi Hilton???

No geedubya , I was 19 when Gough Whitlam abolished the draft in December '72. Twenty year olds were eligible for up to a two year, all expenses paid, trip to S. E. Asia. A few of my friends went but, if my number had come up, my mum had already booked me in with some of my cousins who ran oyster leases in Boonoroo - a hard place to find. She reckoned that my old man had done his bit in Tobruk,(he was a "Rat"), New Guinea, (last amphibious landing at Milne Bay) and Borneo and the rest of Australia could be "all the way with LBJ" but she'd be fucked if she was raising kids to be "cannon fodder", as she put it. Things were pretty tense in my household for a while then Whitlam pulled the pin and everyone breathed a sigh of relief. We all had the dubious pleasure of watching the Vietnam War unfold on our 6 o'clock news for six or so years so most of us got the picture. I stood outside the "Hanoi Hilton" today, (or at least what was left of it), and I still remember the POW's being paraded outside. Almost got into an argument with a village elder while I was on a pushbike tour here. He remembered it all too. So, yes, it feels a little strange to walk the streets of Hanoi, even after 40 years.

People here are fabulous - friendly and mainly tolerant, not at all what I had expected in what is still a Communist country. I have enjoyed myself immensely.

Sorry Mailman if I have politicized your thread. Not my intention.

People here are fabulous - friendly and mainly tolerant, not at all what I had expected in what is still a Communist country. I have enjoyed myself immensely.

Sorry Mailman if I have politicized your thread. Not my intention.

No worries David, all very interesting. I'm happy you are enjoying your tour. It is said to be very beautiful. By the way , the draft here in the States ended the year I became eligible,

My brother was not so fortunate. Although by sheer luck he was stationed here in the States and never was sent to Vietnam.

My brother was not so fortunate. Although by sheer luck he was stationed here in the States and never was sent to Vietnam.

G'day Dave,No geedubya , I was 19 when Gough Whitlam abolished the draft in December '72. Twenty year olds were eligible for up to a two year, all expenses paid, trip to S. E. Asia. A few of my friends went but, if my number had come up, my mum had already booked me in with some of my cousins who ran oyster leases in Boonoroo - a hard place to find. She reckoned that my old man had done his bit in Tobruk,(he was a "Rat"), New Guinea, (last amphibious landing at Milne Bay) and Borneo and the rest of Australia could be "all the way with LBJ" but she'd be fucked if she was raising kids to be "cannon fodder", as she put it. Things were pretty tense in my household for a while then Whitlam pulled the pin and everyone breathed a sigh of relief. We all had the dubious pleasure of watching the Vietnam War unfold on our 6 o'clock news for six or so years so most of us got the picture. I stood outside the "Hanoi Hilton" today, (or at least what was left of it), and I still remember the POW's being paraded outside. Almost got into an argument with a village elder while I was on a pushbike tour here. He remembered it all too. So, yes, it feels a little strange to walk the streets of Hanoi, even after 40 years.

People here are fabulous - friendly and mainly tolerant, not at all what I had expected in what is still a Communist country. I have enjoyed myself immensely.

Sorry Mailman if I have politicized your thread. Not my intention.

Yes at least Gough did one good thing a little late for some of us..........I have never been to Vietnam.

The arsehole Federal politician who lived up the street sent his son to Canada to avoid National Service.

My wife wants to visit maybe next year.

Will you still remember how to ride your XS when you return???

Not sure I was any good on it before I left. Still, the days of scraping my pegs going up Mt Cootha after six or seven cones are well and truly behind me. Lucky if I can remember where I put the keys these days. Got six months left on the resto yet so it will all be a new experience to me. Totally agree about Gough. That "nom de plume" of yours isn't a dig at George W by any chance??

Cheers

Cheers

G'day dave,Not sure I was any good on it before I left. Still, the days of scraping my pegs going up Mt Cootha after six or seven cones are well and truly behind me. Lucky if I can remember where I put the keys these days. Got six months left on the resto yet so it will all be a new experience to me. Totally agree about Gough. That "nom de plume" of yours isn't a dig at George W by any chance??

Cheers

Not a dig at George W but my actual initials are GW and this bloke I worked with for a helicopter company in New Guinea he came from Alaska and called me "geedubya" and it stuck.

Hurry home and get stuck into your project so you can get your knees in the breeze.

What model do you have mate??

'78 Special. Going for the 'close as possible' restoration so it is taking some time. I am a dubious, if somewhat ambitious, mechanic so threads like Bob's here have proved invaluable. Shame you've got a Townsville postcode or we could organise a bit of riding and a beer or three. Might be able to come up with something communal 'cause Skull is in NQ and Mick is in Airlie. Maybe next year we could do as XS get together in Shute Harbour. That'll give me time to finish the resto and them time to clean up after Cyclone Deb.

Cheers

Cheers

No worries David, all very interesting. I'm happy you are enjoying your tour. It is said to be very beautiful. By the way , the draft here in the States ended the year I became eligible,

My brother was not so fortunate. Although by sheer luck he was stationed here in the States and never was sent to Vietnam.

I tell you Bob, we're twins separated by the Pacific. We even look similar although I'm carrying a few unnecessary kilos courtesy of Pete's alter ego and, you're a damn sight better with a spanner then I'll ever be. I'm tracing the family tree!!

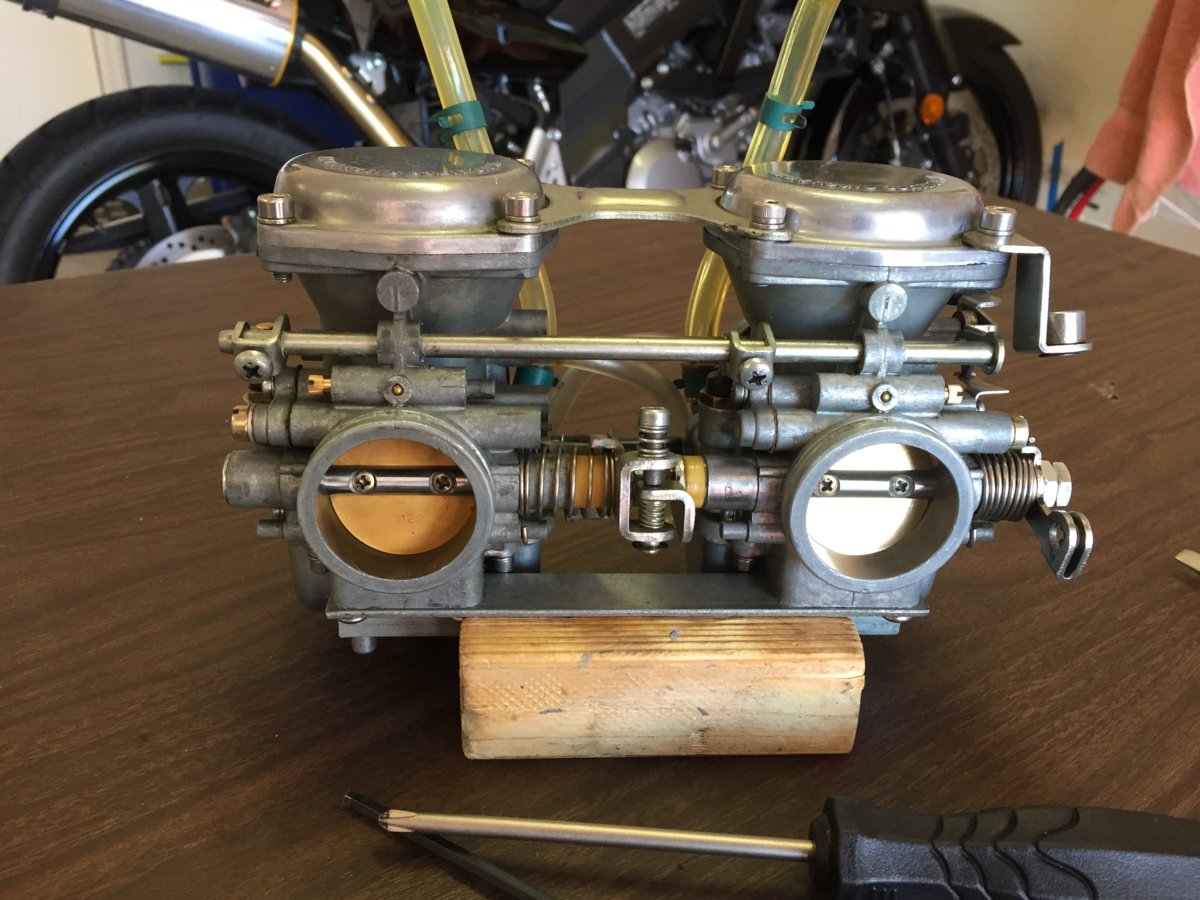

CAN THIS CARBURETOR BE SAVED?

"This week we find our reluctant shade tree mechanic once again tearing his carbs apart after having them hang open on his last ride,

With his motor screaming like a banshee he limped it home and now he's removed his carbs ( once again ) to try to figure out what's wrong."

Ok, I pulled the carburetors and have them on my bench. ( 15 minutes from walking out in the garage to having them on my bench. Ha!)

I then separated the carburetors to try and isolate the problem. And I think I found a clue.

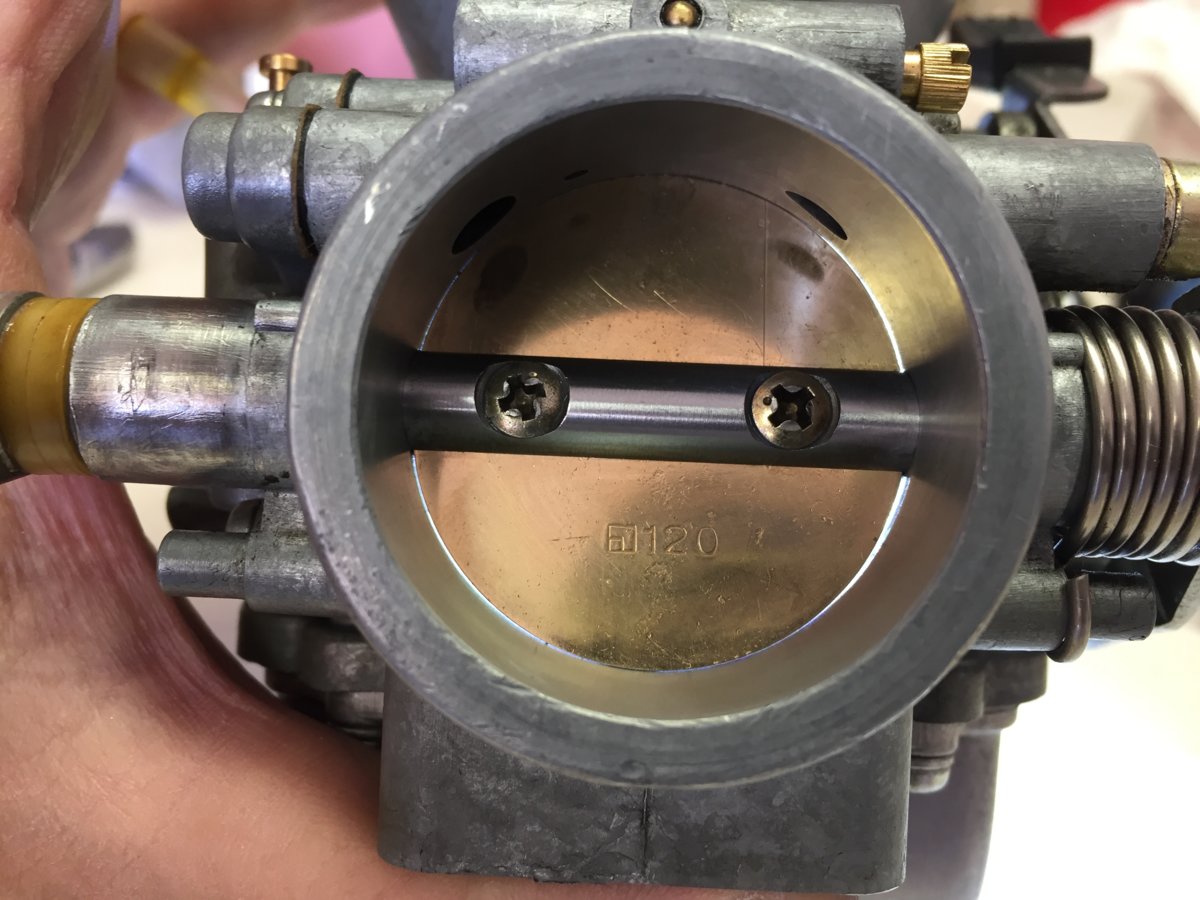

I am not holding the throttle open in this photo, do you think this is a problem? Lol

Alright time to break this one down, but first!

I need me a proper Carb Stick like the one my good friend Robin made!

Feast your eyes on Stick It 2.0! Sorry Robin , don't be jealous, your Stick It is so yesterday!

Took me about 15 minutes to whittle this bad boy.

This works SO good! I'm going to have to make one I wouldn't be embarrassed to leave lying out somewhere! Haha

This is the left side carburetor that came to me with wear on the inside of the throttle body. I suspected that, that my be the source of my hang up. Here you can see where the butterfly has worn into the carburetor body.

To try and remedy this, the previous owner had fashioned a really cool shim out of a peice of beer can which he then wired in place and covered with some sort of black goo.

I removed all that when I rebuilt the carbs and replaced it with a very thin washer that I made.

Thinking that where the butterfly had worn into the body might be the source of the sticking, I took some 1000 grit wet sand paper and WD-40 and very carefully smoothed out the sharp edges in the bore of the carburetor. I wound up with this.

I then carefully blew compressed air through all the orifices.

I do not have precision measuring tools however I took the throttle shaft and held it against a steel ruler from a framing square that I know to be true and checked it for straightness. I checked it in all sides and it layed nice and flat against the edge of the ruler. So using a thin film of white grease on the throttle shaft I began reassembly. I made sure to install the return spring in the assembly so that there would be normal side pressure and then inserted the throttle plate and used the snap the throttle method to center the plate. I loctited the screws and assembled everything.

You can see here , with the back lighting, the wear on the right side. It didn't really seem to adversely affect the way the motor ran.

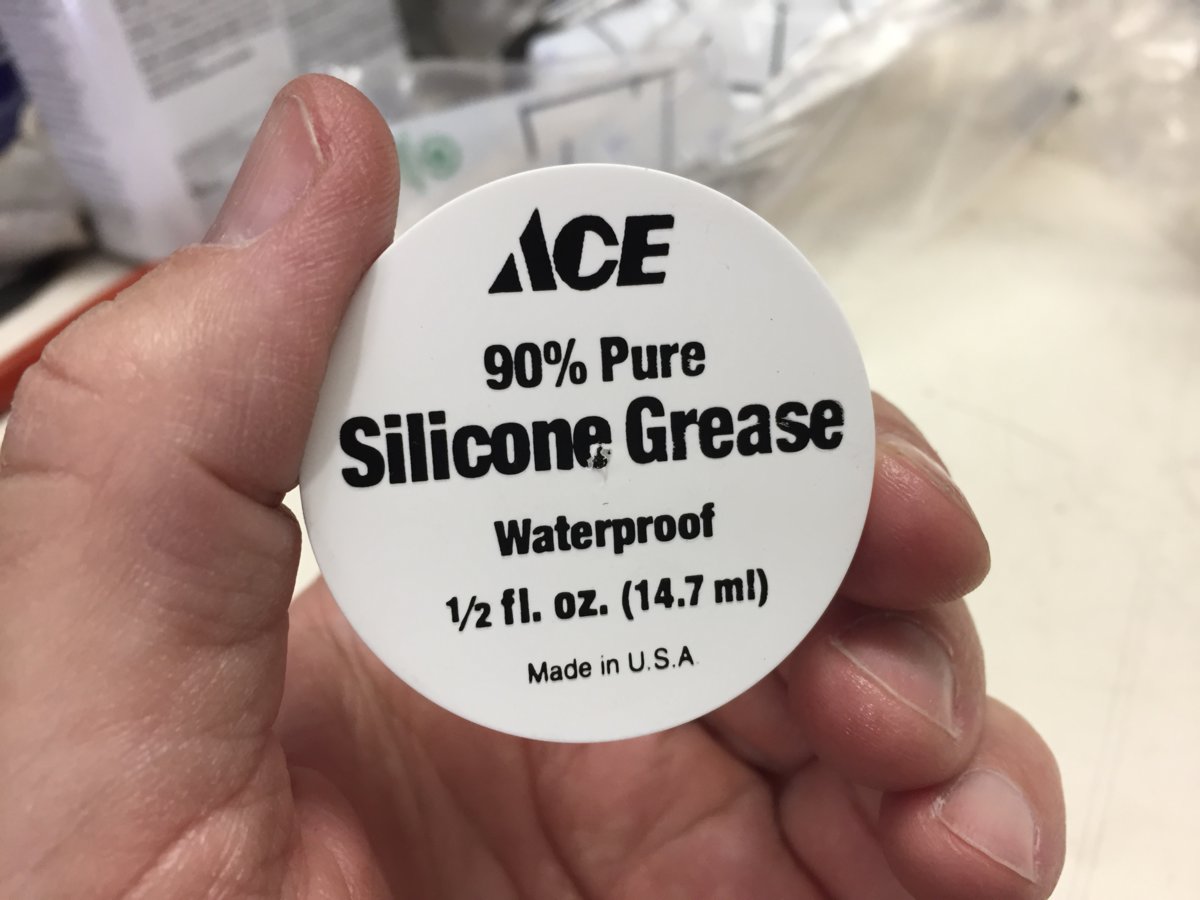

I tried the throttle action again and while it felt better it still felt like it was suffering from "sticktion" and surprisingly it didn't feel like it was sticking at the point where the butterfly had worn the throttle body, but BEFORE that point. So.... I tore it all apart AGAIN and ran to Ace Hardware to buy some silicone lubricant.

This is what I bought.

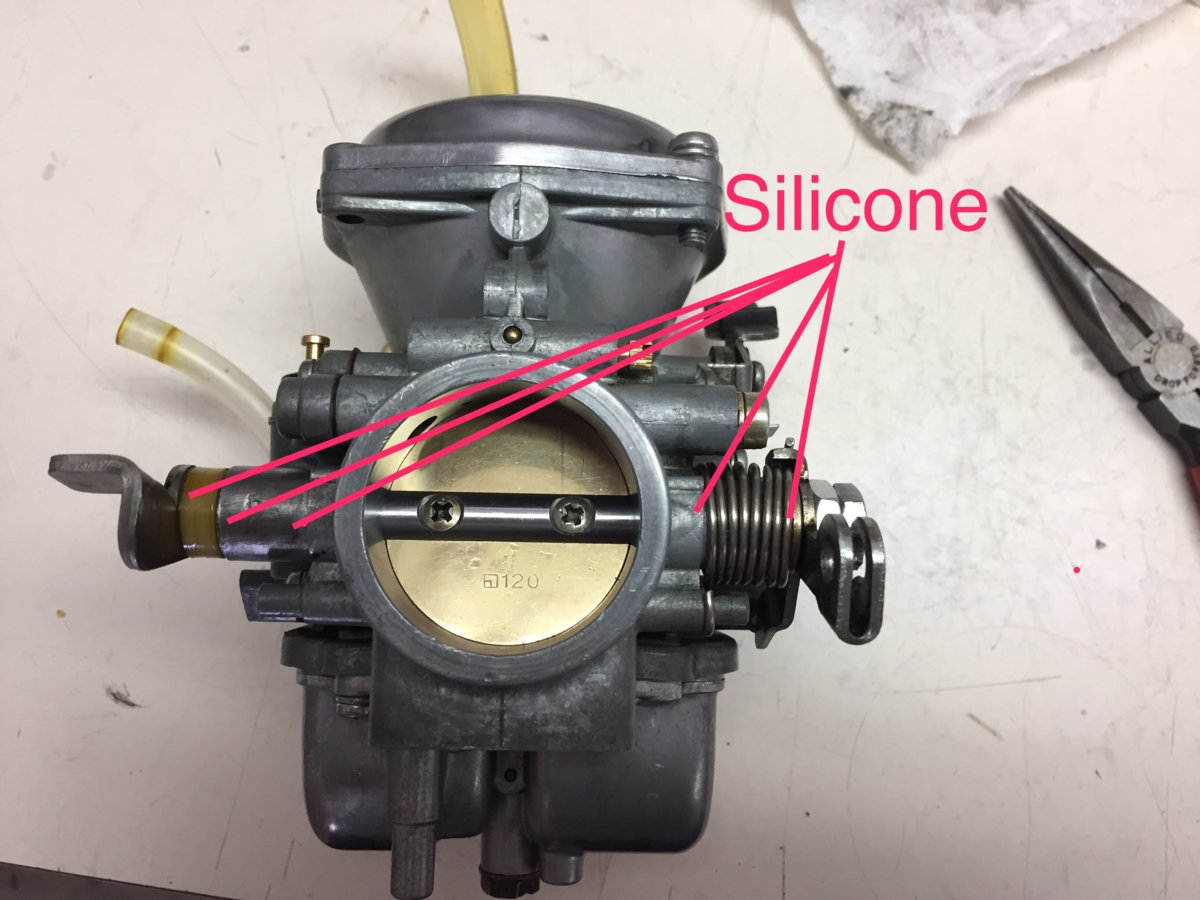

From the plumbing section. A small container of plumbers grease, it's a gel almost liquid and it doesn't take much. It's safe on all rubber and plastic. This is some really slippery stuff. I used a Q-tip and applied it on all friction points, anywhere that rubs together including the throttle shaft bores.

( which look to be bronze bushings , but not split and do not look to be replaceable)

Now we're getting somewhere! The action is smooth as butter! When you open and release the throttle it snaps shut nice and quick.

Tomorrow I will put the carburetors back together and reinstall them. Will it work?

I don't know, right now I'm going to go have a BEvERage. Stay tuned.

Bob

"This week we find our reluctant shade tree mechanic once again tearing his carbs apart after having them hang open on his last ride,

With his motor screaming like a banshee he limped it home and now he's removed his carbs ( once again ) to try to figure out what's wrong."

Ok, I pulled the carburetors and have them on my bench. ( 15 minutes from walking out in the garage to having them on my bench. Ha!)

I then separated the carburetors to try and isolate the problem. And I think I found a clue.

I am not holding the throttle open in this photo, do you think this is a problem? Lol

Alright time to break this one down, but first!

I need me a proper Carb Stick like the one my good friend Robin made!

Feast your eyes on Stick It 2.0! Sorry Robin , don't be jealous, your Stick It is so yesterday!

Took me about 15 minutes to whittle this bad boy.

This works SO good! I'm going to have to make one I wouldn't be embarrassed to leave lying out somewhere! Haha

This is the left side carburetor that came to me with wear on the inside of the throttle body. I suspected that, that my be the source of my hang up. Here you can see where the butterfly has worn into the carburetor body.

To try and remedy this, the previous owner had fashioned a really cool shim out of a peice of beer can which he then wired in place and covered with some sort of black goo.

I removed all that when I rebuilt the carbs and replaced it with a very thin washer that I made.

Thinking that where the butterfly had worn into the body might be the source of the sticking, I took some 1000 grit wet sand paper and WD-40 and very carefully smoothed out the sharp edges in the bore of the carburetor. I wound up with this.

I then carefully blew compressed air through all the orifices.

I do not have precision measuring tools however I took the throttle shaft and held it against a steel ruler from a framing square that I know to be true and checked it for straightness. I checked it in all sides and it layed nice and flat against the edge of the ruler. So using a thin film of white grease on the throttle shaft I began reassembly. I made sure to install the return spring in the assembly so that there would be normal side pressure and then inserted the throttle plate and used the snap the throttle method to center the plate. I loctited the screws and assembled everything.

You can see here , with the back lighting, the wear on the right side. It didn't really seem to adversely affect the way the motor ran.

I tried the throttle action again and while it felt better it still felt like it was suffering from "sticktion" and surprisingly it didn't feel like it was sticking at the point where the butterfly had worn the throttle body, but BEFORE that point. So.... I tore it all apart AGAIN and ran to Ace Hardware to buy some silicone lubricant.

This is what I bought.

From the plumbing section. A small container of plumbers grease, it's a gel almost liquid and it doesn't take much. It's safe on all rubber and plastic. This is some really slippery stuff. I used a Q-tip and applied it on all friction points, anywhere that rubs together including the throttle shaft bores.

( which look to be bronze bushings , but not split and do not look to be replaceable)

Now we're getting somewhere! The action is smooth as butter! When you open and release the throttle it snaps shut nice and quick.

Tomorrow I will put the carburetors back together and reinstall them. Will it work?

I don't know, right now I'm going to go have a BEvERage. Stay tuned.

Bob

As usual nice work Bob. You have really cleaned and sorted them nicely. I just used dielectric grease today as everything is closed here for the holiday. We don't have Ace here in Canada but I will look for something similar. And we're on onto revisions already I see, Stick It 2 is now released!

I concur with your findings on the throttle shaft bushings and am heading to do a carb update on my thread, just took an important little detour here first. Have a question for 2M re: what we might do with these bushings.

Good luck with the install tomorrow. Will say a word for ya.

If it would make it time, I'd send you one (or several) of these. Cheers!

I concur with your findings on the throttle shaft bushings and am heading to do a carb update on my thread, just took an important little detour here first. Have a question for 2M re: what we might do with these bushings.

Good luck with the install tomorrow. Will say a word for ya.

If it would make it time, I'd send you one (or several) of these. Cheers!

I can really respect the idea of saving those old parts.

Scott

Scott

Yeah, Mailman, yer gettin' those carbs figured out!

Excellent pics and descriptions.

That's a really bad case of plate wear in the bore. An excellent example of not seating the throttle shaft during plate centering. A long-term wear pattern. Hope it doesn't disturb your idle and off-idle too much.

Coupla comments.

I like the shim/thrust washer. That's the kind of thing I've done on all my lead/feed screws on my machining tools. However, yours may be too thick. Although it'll reduce shaft friction, it's shoved the shaft to where the throttle return spring may be too compressed. The holes in the butterfly plate may be off-center relative to the shaft's screw holes, and reduce any adjustable range for butterfly centering. But, if you got the plate to center, the return spring and lever aren't binding, and the throttle rotates freely, then probably not an issue.

Took forever to research that ACE plumbers grease. Best I could determine is that the mystery 10% is NOT petroleum based. So, okey-dokey on your shaft seals.

Does the other carb's butterfly and throat show any similar wear signs?

Excellent pics and descriptions.

That's a really bad case of plate wear in the bore. An excellent example of not seating the throttle shaft during plate centering. A long-term wear pattern. Hope it doesn't disturb your idle and off-idle too much.

Coupla comments.

I like the shim/thrust washer. That's the kind of thing I've done on all my lead/feed screws on my machining tools. However, yours may be too thick. Although it'll reduce shaft friction, it's shoved the shaft to where the throttle return spring may be too compressed. The holes in the butterfly plate may be off-center relative to the shaft's screw holes, and reduce any adjustable range for butterfly centering. But, if you got the plate to center, the return spring and lever aren't binding, and the throttle rotates freely, then probably not an issue.

Took forever to research that ACE plumbers grease. Best I could determine is that the mystery 10% is NOT petroleum based. So, okey-dokey on your shaft seals.

Does the other carb's butterfly and throat show any similar wear signs?

Yeah, Mailman, yer gettin' those carbs figured out!

Excellent pics and descriptions.

But, if you got the plate to center, the return spring and lever aren't binding, and the throttle rotates freely, then probably not an issue.

Does the other carb's butterfly and throat show any similar wear signs?

The other carb, looks and acts perfectly.

Something I forgot to mention, the way the carburetor was set up to begin with, the end of the throttle shaft had a big thick lock washer under the nut. It looks too heavy to be stock, and if you crank the nut down enough to compress the lock washer, every thing just binds up to the point that nothing turns.

I bought another nut. The first nut I ran it down just finger tight, then put the second nut on as a jam nut. It took the pressure off of the butterfly and all the other pivot points and let everything rotate more freely.

Huh, that's weird Bob. all my carbs have that locknut between the throttle lever arm and the outer nut.

The throttle shaft is cutaway to 2 flats for the inner special rectangular holed washer. The cutaway throttle shaft shoulders extend just proud of the outside throttle shaft bore so that it would be impossible to tighten to the point of binding.

Edit 1: I still have one of my first 78/79 sets somewhat disassembled and will measure and let you know how much this protrudes beyond the end of the throttle shaft bore. I know you're working with a 76/77 carb set and I'm sure no expert but the bodies look the same as the 78/79's. In any event it'll give you a reference point.

I wonder if someone has swapped in some other shorter throttle shafts in your carbs? Measure throttle shaft length from now on is on my to do list.

Edit 2: Had another thought on this Bob. Is it this carb you put the shim washer on or the other one? Can't tell for sure from the picture. You said it was on the left carb so that would be this one. 2M picked up on this in his post #734, and that might be your problem. Maybe remove that shim washer, or put in a thinner one and you'll have room for the locknut again.

Now that you have the butterfly properly centered, do you still need that shim?

Although your extra jam nut setup should work fine too I guess and save you taking it apart again....lol.

The throttle shaft is cutaway to 2 flats for the inner special rectangular holed washer. The cutaway throttle shaft shoulders extend just proud of the outside throttle shaft bore so that it would be impossible to tighten to the point of binding.

Edit 1: I still have one of my first 78/79 sets somewhat disassembled and will measure and let you know how much this protrudes beyond the end of the throttle shaft bore. I know you're working with a 76/77 carb set and I'm sure no expert but the bodies look the same as the 78/79's. In any event it'll give you a reference point.

I wonder if someone has swapped in some other shorter throttle shafts in your carbs? Measure throttle shaft length from now on is on my to do list.

Edit 2: Had another thought on this Bob. Is it this carb you put the shim washer on or the other one? Can't tell for sure from the picture. You said it was on the left carb so that would be this one. 2M picked up on this in his post #734, and that might be your problem. Maybe remove that shim washer, or put in a thinner one and you'll have room for the locknut again.

Now that you have the butterfly properly centered, do you still need that shim?

Although your extra jam nut setup should work fine too I guess and save you taking it apart again....lol.

Last edited:

Haha, maybe I've done a Rube Goldberg repair here with that homemade shim. Yes the carburetor that has the shim is the same one that was binding if I tightened up the nut with the lock washer.

So.... maybe you and 2M are correct about the shim being too thick or not even necessary.

I was just trying to make sure that butterfly didn't dig into the carb body anymore.

All I can say right now is that the butterfly looks to be well centered and everything moves freely.

This morning I will re connect the two carburetors and get them back in the bike and we shall see if this pig will fly! Haha

So.... maybe you and 2M are correct about the shim being too thick or not even necessary.

I was just trying to make sure that butterfly didn't dig into the carb body anymore.

All I can say right now is that the butterfly looks to be well centered and everything moves freely.

This morning I will re connect the two carburetors and get them back in the bike and we shall see if this pig will fly! Haha

Ok , all back together, I was very careful upon re assembly going slow and " floating" the carbs and all the linkages and connecting plates to make sure that nothing was in a bind, constantly checking the throttle action.

Everything is good.

I bench synched the carbs using a slip of paper to check for clearance on the butterflies.

Since I already had the carb with the shim put together and it works so smoothly, I have decided I want to try it out.

By golly I made the darn thing and I'm stubborn by nature. What can I say, I'm a Missouri mule. Here we are ready to go.

I also swapped out the Phillips screws with stainless Allen head screws.

By the way, you know what's fun?

Seeing this laying on the bench after assembling your carburetors! Haha

Everything is good.

I bench synched the carbs using a slip of paper to check for clearance on the butterflies.

Since I already had the carb with the shim put together and it works so smoothly, I have decided I want to try it out.

By golly I made the darn thing and I'm stubborn by nature. What can I say, I'm a Missouri mule. Here we are ready to go.

I also swapped out the Phillips screws with stainless Allen head screws.

By the way, you know what's fun?

Seeing this laying on the bench after assembling your carburetors! Haha

Similar threads

- Replies

- 785

- Views

- 82K

- Replies

- 3

- Views

- 2K

- Replies

- 1

- Views

- 2K