True indeed - and I will likely have white or near-white walls and ceiling with a somewhat darker floor that is mono-coloured so that I can find the many 10mm sockets I will drop on it over the years.

P

P

I hope those years are many.can find the many 10mm sockets I will drop on it over the years.

Without them slick epoxy will be the death of you.Don't do one of those speckled floor epoxy finishes, drop a small screw on the floor and try and find it

I plan to use one of those grainy surface additives to make it non-slip - but the colour of the floor will be monotone so that I can see the many things that I will inevitably drop on it.Without them slick epoxy will be the death of you.

Hands and knees with a flashlight....

To clarify, I didn't imply gritless, just not those decorative flecks, solid color with grit is fineWithout them slick epoxy will be the death of you.

Hands and knees with a flashlight....

Yup -that is where I am headed.To clarify, I didn't imply gritless, just not those decorative flecks, solid color with grit is fine

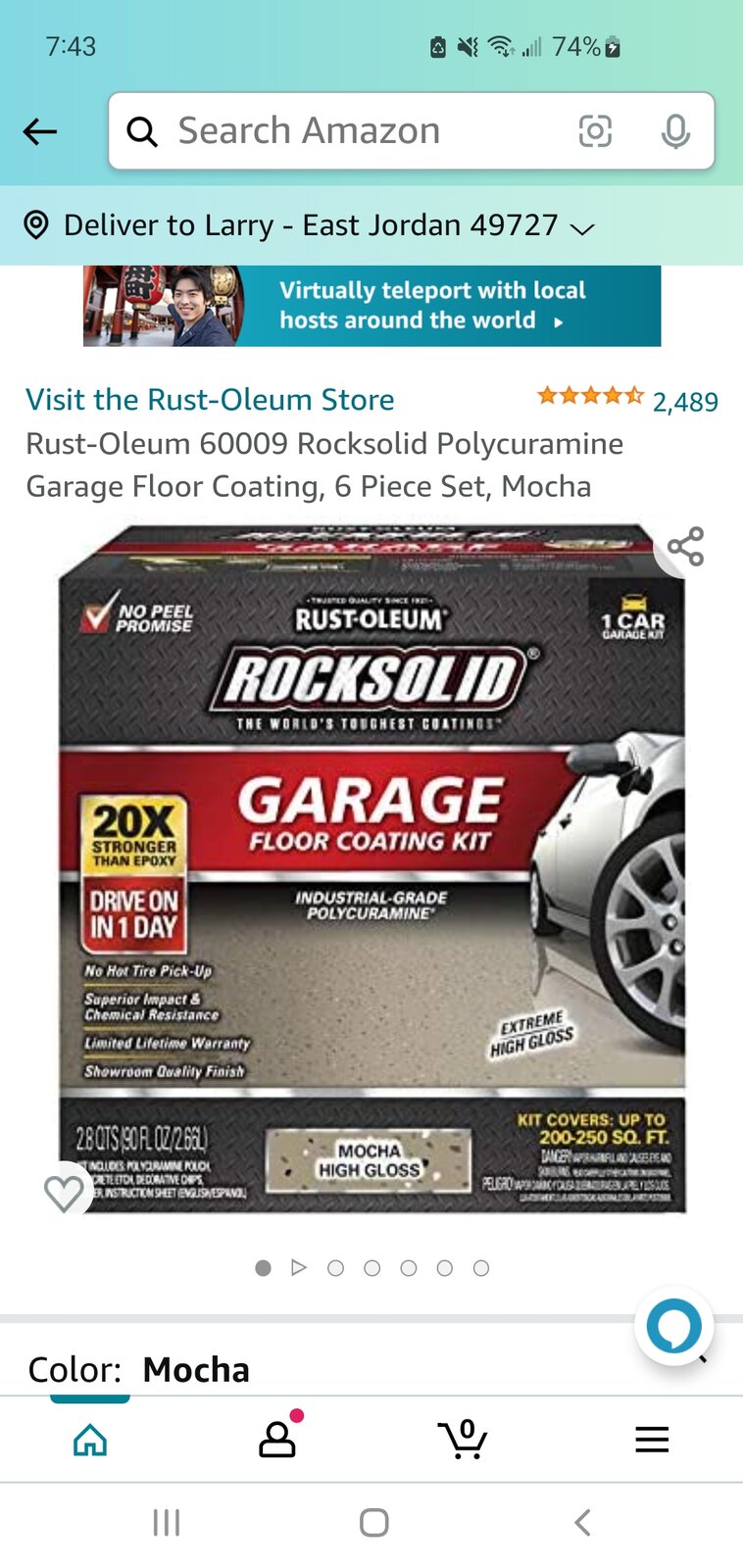

After pouring my polebarn floor, I waited 30 days, then used a concrete etching you can get at home depot. Power washed the floor afterward. Let it dry another 3-4 days, then I used this product called "Rocksolid" from Rustoleum. Note they also sell a clear coat 2 part epoxy to help protect the grey epoxy, but I didn't like how the clearcoat made the surface look. I quit clearcoating after doing one corner section. It yellowed over time, while the rest of the floor still looks great. This 2 part epoxy is tough. I've even spilled aircraft paint remover on it and wiped it up after a couple of minutes and it didn't bubble at all. Gas and oil won't hurt it one bit. I will say that it doesn't cover near as much as advertised, and I had a couple areas where air bubbles formed. I called Rustoleum direct to voice my concern and they sent me enough to re-cover the trouble spots and enough to finish the rest of the floor, at no additional cost. It's not cheap but was impressed how they stood behind their product. I did use the flakes....and it is difficult to find anything you drop like everyone stated, but I knew that going in. I wanted it to look good.Yup -that is where I am headed.

QUESTIONS:

1) anybody know how long after the floor has been poured do I need to wait before moving forward with the coating?

2) any tips as to a good brand of coating to use?

3) any other tips on applying such a coating to the floor?

Just let me come up and spray it with my Sata, I'm good at getting non skid finishes on hoods and roofs.Yup - something like that but I think they can mix it at the paint store for more even coverage.

I will definitely have some grit in the paint.

P

After pouring my polebarn floor, I waited 30 days, then used a concrete etching you can get at home depot. Power washed the floor afterward. Let it dry another 3-4 days, then I used this product called "Rocksolid" from Rustoleum. Note they also sell a clear coat 2 part epoxy to help protect the grey epoxy, but I didn't like how the clearcoat made the surface look. I quit clearcoating after doing one corner section. It yellowed over time, while the rest of the floor still looks great. This 2 part epoxy is tough. I've even spilled aircraft paint remover on it and wiped it up after a couple of minutes and it didn't bubble at all. Gas and oil won't hurt it one bit. I will say that it doesn't cover near as much as advertised, and I had a couple areas where air bubbles formed. I called Rustoleum direct to voice my concern and they sent me enough to re-cover the trouble spots and enough to finish the rest of the floor, at no additional cost. It's not cheap but was impressed how they stood behind their product. I did use the flakes....and it is difficult to find anything you drop like everyone stated, but I knew that going in. I wanted it to look good.

View attachment 227010

Yes, it can get a bit slick when wet. They make a packet of abrasive you can mix in, but I opted not to use it. It hasn't been an issue and I like how I can easily squeegy the floor. Biggest "hazard" I've encountered is when I pull my truck in during foul weather....need to be careful stepping out.do you find the floor slippery when it is wet?

Yes, it can get a bit slick when wet. They make a packet of abrasive you can mix in, but I opted not to use it. It hasn't been an issue and I like how I can easily squeegy the floor. Biggest "hazard" I've encountered is when I pull my truck in during foul weather....need to be careful stepping out.

Hey Pete,Yup -that is where I am headed.

QUESTIONS:

1) anybody know how long after the floor has been poured do I need to wait before moving forward with the coating?

2) any tips as to a good brand of coating to use?

3) any other tips on applying such a coating to the floor?

Thanks for the website info....and I asked Hyperlites for their recommendations (free - just email them) and this came back about 25 minutes later!

_________________________________________________

Hi Peter,

Welcome to Hyperlite! We made a lighting simulation, based on the information you provided.

You need 6pcs 100w Hero Series (4000K or 5000K according to your preference). You can review the attached pictures for more details.

The lighting simulations are just for your reference, you can adjust them according to the real situation. To have more information about our products or if you want to complete your order, please visit:

https://hi-hyperlite.com/products/led-high-bay-light-hero-black-4000k

And if you have any questions, please do not hesitate to contact us back.

Regards,

Hyperlite Support Service.

sales@hi-hyperlite.com | www.hi-hyperlite.com |

Choosing Hyperlite is choosing premier lighting and the ultimate service.

View attachment 227123View attachment 227124View attachment 227125

I am also looking at floor paint / epoxy. I want a non-slip surface and I got a quote from a local firm of more than $5K <holy crappola!!!) for them to do it - so, this will be a DIY affair methinks.