Indeed, Jim. An old mentor of mine was fond of saying something similar: "Get your cottonpickers off that carburetor! How many times do I have to say it? Ignition first!"

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RS 36 Mikuni Carb fuel consumption

- Thread starter Sandgroper

- Start date

Sandgroper

XS650 Member

Hello 650Skull, i'm still trying to work out how to send you a conversation to send you email address which I am very thankful for.I have a PDF of the Mikuni-Sudco tuning manual. Its 19mb so to big to post up here. I can get it to you with an email. Send me a conversation and we can sort out the E-mails.

View attachment 216070View attachment 216071View attachment 216072

ok thanks 650Skull, that is really good of you! could you please tell me how to send a conversation? I swing hammers for a living, not computers (although one day it may be possible) not really up with the high tech stuff.I have a PDF of the Mikuni-Sudco tuning manual. Its 19mb so to big to post up here. I can get it to you with an email. Send me a conversation and we can sort out the E-mails.

View attachment 216070View attachment 216071View attachment 216072

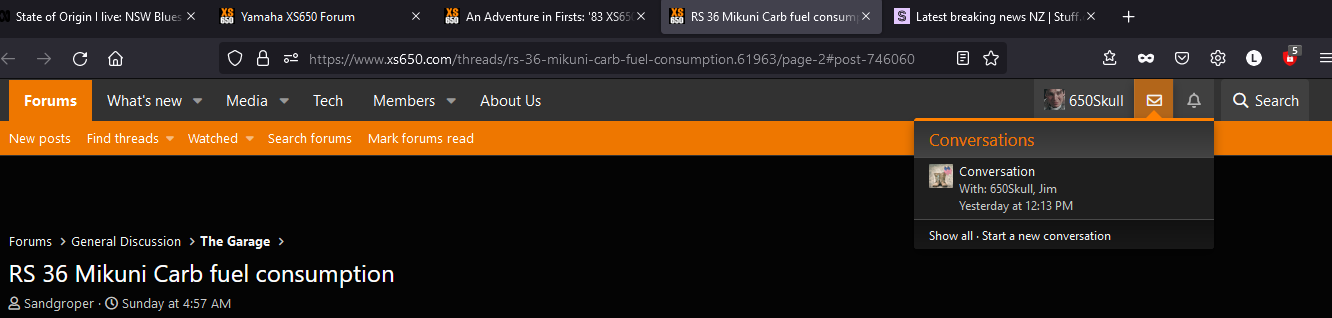

Top left corner there is an Envelope Icon/symble next to your handle, (site name). ..............Left mouse button click on the icon and this Dropbox appears

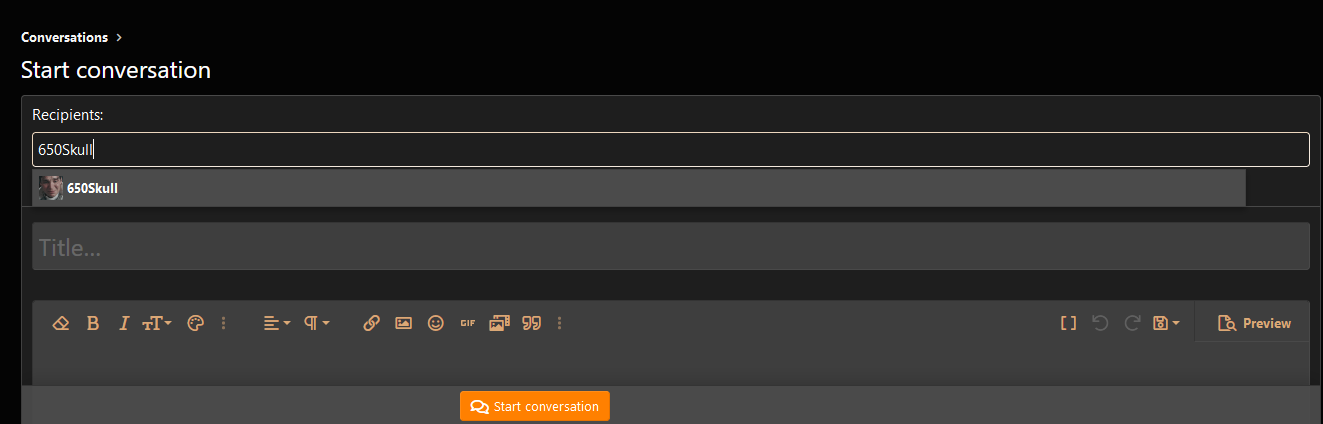

Click on "Start new Conversation" and this box opens up

Type in 650Skull like i have and the program should show my name and Avatar....................... If That hasn't shown up then check your spelling. it will only show up when you have got it right

Make a title then post a message and hit "Start Conversation"

Click on "Start new Conversation" and this box opens up

Type in 650Skull like i have and the program should show my name and Avatar....................... If That hasn't shown up then check your spelling. it will only show up when you have got it right

Make a title then post a message and hit "Start Conversation"

Or You could just PM him skull

Sandgroper

XS650 Member

hello again grizld1, so to answer your few questions;That's the item, Skull! Thanks for stepping up. I'm not a lawyer, but the Sudco book is copyrighted material, so I suspect that posting it on the site could be a problem, to put it mildly, so best to use email anyway. You're a good man, I don't care what they say about you.

Read slowly and carefully, SG, and post some pics of your carbs, preferably removed from the bike. A lot of custom work has to be done to fit RS carbs for the XS650, with some opportunities for error. The only lines that should be joined are the fuel lines and the accelerator pump reservoir lines between the float bowls. All other lines are vent lines and there are lots of those. They need to be open to atmosphere.

Note that the 34 mm. TM 4-stroke flat slide pumper doesn't appear in the Sudco manual. That's because the bean counters at Mikuni America don't import it, so Sudco, the larger of their two U.S. distributors, don't get it. It's available in Europe and elsewhere. Have a look here: https://www.mikuni-topham.de

A few questions: who did the carb mods, and what if any motor mods were done in addition to the displacement increase? In particular, were ports modified, was an aftermarket camshaft installed, was deck height altered, was cam timing set correctly, and if an aftermarket cam was installed, where did you set valve lash? Also who did the carb and motor work?

Don't let this stuff stress you. Troubleshooting is a process of elimination. It's usually a mistake to assume that your trouble has only one cause and that you can logic your way to it. For one thing, a problem can be caused by more than one defect. The more you think in terms of checking things off a list one inspection at a time, the farther ahead you'll be. Try to derive a sense of accomplishment from every item you eliminate, and have fun with the project.

The Carb mods were done by a reputable Mukini stockist in Australia. they were bought already in a bank of two and tuned pre sale.

The motor mods are as follows, I've thrown everything in there modification or not - Big bore 750 barrel kit, Tri Spark Digital Electronic Ignition, Performance Cam, new alternator stator, 5th Overdrive gear, performance high volume oil pump ,reed type engine breather valves, performance clutch springs, new transmission bearings, reconditioned crank and new bearings,17 T drive sprocket 32 T rear sprocket (will be going 34 teeth later) exhaust seats re-cut and all valves re-lapped, cam followers diamond honed, intake ported to fit 36mm manifold. Valve lash set to Intake - .003'' (.075mm) , Exhaust - .006" (.15mm) Spark Plugs NGK BR7ES

Motor work (bottom end) done by me and trusty old Mr Clymer Manual

Top end work and marry up of top and bottom done by an engine builder.

Tuning was attempted by a mechanic but after the starter gear clip failed on him for a second time I had to pick up the bike and fix it myself. Thats when I started reading your great topics here and finally fixed it myself with a bit of patience and late nights.

As for stress? nah.. its a hobby, its suupposed to be enjoyable. When I feel it is getting me annoyed I find something else to do then come back later. Sometimes I come up with better ideas after some sleep!

We all have to learn sometimeOr You could just PM him skull

Sandgroper

XS650 Member

I did everything you said then went to press start conversation and it said I can not send you anything?Top left corner there is an Envelope Icon/symble next to your handle, (site name). ..............Left mouse button click on the icon and this Dropbox appears

View attachment 216132

Click on "Start new Conversation" and this box opens up

View attachment 216133

Type in 650Skull like i have and the program should show my name and Avatar....................... If That hasn't shown up then check your spelling. it will only show up when you have got it right

Make a title then post a message and hit "Start Conversation"

I did everything you said then went to press start conversation and it said I can not send you anything?

Sorry about that..........My settings were set wrong. Changed them so a conversation will get through now

Carbs are never tuned pre sale. They may be well baselined, but fine tuning has to take place on a running motor. The "engine builder" who figured that the intake ports needed to be hogged out in a head originally designed for 38 mm.carbs ought to have his fingers amputated with a cutoff wheel on his own die grinder. Let's hope the fool didn't remove too much material or go too deep into the port. Never heard before of a mechanic begging off on a job because the electric foot didn't work. You fell among thieves, but you didn't need a good Samaritan, you picked yourself up and continued the march. Good on ya!

What aftermarket cam did you have installed? Get the valve timing specs. Whose new stator did you install? The rotor tends to go bad with age, but we seldom see the OE stator fail. I'd trust a used OE stator that meters out over a Chiwanese repop any day, and I'd trust a properly rewound OE rotor over an OE rotor with 40-plus years on its windings or anything from Chiwan.

Those valve lash numbers are too tight for any XS650 performance cam that I know of. You really need to identify the thing and get the following specs: operating valve lash, inspection valve lash, and valve opening and closing events. I hope you didn't buy that Taiwanese "XS Performance" "billet"cam that used to be peddled by Mike's XS and Heiden Tuning. If you did, the only reliable way to time the POS is by fooling with deck height. Don't even think about trying to mount the sprocket on the slots to time the cam. There's a reason why every other maker of adjustable sprocket setups uses a three point mount; two 7 mm. bolts won't cut it. Mike's and Jerry's no longer sell the thing, but the grind is a clone of the Megacycle 250-00. If that's what you have, specs are as follows:

Running valve lash, intake and exhaust: .006". Inspection valve lash: .040". Intake open/close/lobe center:102* BTDC/66*BBDC/110*. Exhaust open/close/lobe center: 60* ABDC/32*ATDC/104*. The Shell #1 grind is the most popular street and short track performance cam. Running valve lash, I/E: .006/.012. Inspection valve lash: .050". Lobe center=100*, intake and exhaust. IO/IC: 25* BTDC,/45*BBDC. EO/EC: 45*ABDC/25*ATDC. The IO is sometimes ground as far advanced as 20* BTDC. My cam opens the intakes at 22*. After a lot of fooling trying to spread the error, I got the best results by timing to the EO and letting the intake events fall where they may.

Here's where I'd start. First, correct the running valve lash and confirm power supply to the coil. Then select one of the good methods of locating TDC posted here and check the accuracy of your timing marks. A "good" method involves reading degrees BTDC and ATDC at the same drop from an approximate TDC position. Half of the difference between the two measurements gives you the correction factor. Near TDC the piston moves very little in relation to the crank, and this procedure eliminates resulting inaccuracies. Verify your timing marks, then check ignition timing, both fully retarded and fully advanced.

One more thing: You can trust what you read in Yamaha factory service manuals (except for the odd SNAFU in converting Newton meters to foot pounds), but Clymer and Haynes manuals are full of misinformation. Check their material against the factory pubs. There are free downloads available from several sites. Here's one: https://www.biker.net

What aftermarket cam did you have installed? Get the valve timing specs. Whose new stator did you install? The rotor tends to go bad with age, but we seldom see the OE stator fail. I'd trust a used OE stator that meters out over a Chiwanese repop any day, and I'd trust a properly rewound OE rotor over an OE rotor with 40-plus years on its windings or anything from Chiwan.

Those valve lash numbers are too tight for any XS650 performance cam that I know of. You really need to identify the thing and get the following specs: operating valve lash, inspection valve lash, and valve opening and closing events. I hope you didn't buy that Taiwanese "XS Performance" "billet"cam that used to be peddled by Mike's XS and Heiden Tuning. If you did, the only reliable way to time the POS is by fooling with deck height. Don't even think about trying to mount the sprocket on the slots to time the cam. There's a reason why every other maker of adjustable sprocket setups uses a three point mount; two 7 mm. bolts won't cut it. Mike's and Jerry's no longer sell the thing, but the grind is a clone of the Megacycle 250-00. If that's what you have, specs are as follows:

Running valve lash, intake and exhaust: .006". Inspection valve lash: .040". Intake open/close/lobe center:102* BTDC/66*BBDC/110*. Exhaust open/close/lobe center: 60* ABDC/32*ATDC/104*. The Shell #1 grind is the most popular street and short track performance cam. Running valve lash, I/E: .006/.012. Inspection valve lash: .050". Lobe center=100*, intake and exhaust. IO/IC: 25* BTDC,/45*BBDC. EO/EC: 45*ABDC/25*ATDC. The IO is sometimes ground as far advanced as 20* BTDC. My cam opens the intakes at 22*. After a lot of fooling trying to spread the error, I got the best results by timing to the EO and letting the intake events fall where they may.

Here's where I'd start. First, correct the running valve lash and confirm power supply to the coil. Then select one of the good methods of locating TDC posted here and check the accuracy of your timing marks. A "good" method involves reading degrees BTDC and ATDC at the same drop from an approximate TDC position. Half of the difference between the two measurements gives you the correction factor. Near TDC the piston moves very little in relation to the crank, and this procedure eliminates resulting inaccuracies. Verify your timing marks, then check ignition timing, both fully retarded and fully advanced.

One more thing: You can trust what you read in Yamaha factory service manuals (except for the odd SNAFU in converting Newton meters to foot pounds), but Clymer and Haynes manuals are full of misinformation. Check their material against the factory pubs. There are free downloads available from several sites. Here's one: https://www.biker.net

Last edited:

Sandgroper

XS650 Member

Ok grizld1 I think I’m going to have to print out your info and do a bit of homework. I have a scary feeling you are right about where I purchased the cam and stator from but I didn’t really have any other choice on my budget and I really just wanted to get out and ride before winter and unfortunately winter is knocking on the door. The good news is that with all this helpful info I can begin to do things right myself. I’m not going to blame anyone for their errors as they were doing the best of their capabilities and it’s hard to find anyone that will work on your bike properly here and get it back to you quickly. I was once told life is about choices and it was my choice to source the parts I did and have them fitted by those people. To be honest I’m happy to work on it myself and learn enough that I will be able to fix it and more bikes in the future.Carbs are never tuned pre sale. They may be well baselined, but fine tuning has to take place on a running motor. The "engine builder" who figured that the intake ports needed to be hogged out in a head originally designed for 38 mm.carbs ought to have his fingers amputated with a cutoff wheel on his own die grinder. Let's hope the fool didn't remove too much material or go too deep into the port. Never heard before of a mechanic begging off on a job because the electric foot didn't work. You fell among thieves, but you didn't need a good Samaritan, you picked yourself up and continued the march. Good on ya!

What aftermarket cam did you have installed? Get the valve timing specs. Whose new stator did you install? The rotor tends to go bad with age, but we seldom see the OE stator fail. I'd trust a used OE stator that meters out over a Chiwanese repop any day, and I'd trust a properly rewound OE rotor over an OE rotor with 40-plus years on its windings or anything from Chiwan.

Those valve lash numbers are too tight for any XS650 performance cam that I know of. You really need to identify the thing and get the following specs: operating valve lash, inspection valve lash, and valve opening and closing events. I hope you didn't buy that Taiwanese "XS Performance" "billet"cam that used to be peddled by Mike's XS and Heiden Tuning. If you did, the only reliable way to time the POS is by fooling with deck height. Don't even think about trying to mount the sprocket on the slots to time the cam. There's a reason why every other maker of adjustable sprocket setups uses a three point mount; two 7 mm. bolts won't cut it. Mike's and Jerry's no longer sell the thing, but the grind is a clone of the Megacycle 250-00. If that's what you have, specs are as follows'

Running valve lash, intake and exhaust: .006". Inspection valve lash: .040". Intake open/close/lobe center:102* BTDC/66*BBDC/110*. Exhaust open/close/lobe center: 60* ABDC/32*ATDC/104*. The Shell #1 grind is the most popular street and short track performance cam. Running valve lash, I/O: .006/.012. Inspection valve lash: .050". Lobe center=100*, intake and exhaust. IO/IC: 25* BTDC,/45*BBDC. EO/EC: 45*ABDC/25*ATDC. The IO is sometimes ground as far advanced as 20* BTDC. My cam opens the intakes at 22*. After a lot of fooling trying to spread the error, I got the best results by timing to the EO and letting the intake events fall where they may.

Here's where I'd start. First, correct the running valve lash and confirm power supply to the coil. Then select one of the good methods of locating TDC posted here and check the accuracy of your timing marks. A "good" method involves reading degrees BTDC and ATDC at the same drop from an approximate TDC position. Half of the difference between the two measurements gives you the correction factor. Near TDC the piston moves very little in relation to the crank, and this procedure eliminates resulting inaccuracies. Verify your timing marks, then check ignition timing, both fully retarded and fully advanced.

One more thing: You can trust what you read in Yamaha factory service manuals (except for the odd SNAFU in converting Newton meters to foot pounds), but Clymer and Haynes manuals are full of misinformation. Check their material against the factory pubs. There are free downloads available from several sites. Here's one: https://www.biker.net

Once I understand what you have written I will definitely get back to you. Like I said I’ve got a stack of homework to do.

Cheers mate!

You have a fine attitude, and I admire it. But IMO when someone takes money for a job that he doesn't know how to do, he's committing theft, and in the case of the party who hogged out your intake ports, theft and vandalism. Off with his fingers!

Last edited:

Sandgroper

XS650 Member

Hello again good people, I have finally had a chance to pull apart my RS36 carbs and have some info I wanted to run past you. The 1st image with the paper is what I pulled out and identified, the second is what else I have available on hand.

Also, would anyone know where would be a good spot on these carbs to put a fitting for a manometer I made for balancing the carbs? I was thinking the hole where the end of the key is pointing?

I would really like to know what position the clip on the jet needle is supposed to be and how many turns out with the mixture screw should be too.

Thanks again everyone!

Also, would anyone know where would be a good spot on these carbs to put a fitting for a manometer I made for balancing the carbs? I was thinking the hole where the end of the key is pointing?

I would really like to know what position the clip on the jet needle is supposed to be and how many turns out with the mixture screw should be too.

Thanks again everyone!

Attachments

That looks like a good location for manometer barbs. Re.the needle, the 9DZH6-50 is the factory needle that comes with the TM36/68, and I suspect that what you have is in fact a pair of TMs banked for the twin. There's nothing wrong with that, it's the same radial smoothbore design group as the RS36, but there are minor differences. I found that the 9DZH6-50 worked nicely with the clip in the middle notch, but that was on my motor, not yours. There is no "correct" needle or mix screw position for a custom carb set on a modified motor. The correct range for the mixture screws is between 1/2 turn and 3 turns out. If you can't get best idle within that range, a change of pilot jets is called for. Re. your present jetting, I like P-6 needle jets, but the P-8s aren't so very rich that they'd cause the kind of gas guzzling that you've experienced.

The first rule of carb tuning is a simple one: "Everything else first." Something is wrong enough to be obvious, and if it doesn't show up when you've inspected TDC location, camshaft timing, running valve lash, and ignition, it's probably down to those enlarged intake ports.

The first rule of carb tuning is a simple one: "Everything else first." Something is wrong enough to be obvious, and if it doesn't show up when you've inspected TDC location, camshaft timing, running valve lash, and ignition, it's probably down to those enlarged intake ports.

Last edited:

Sandgroper

XS650 Member

Good one Grizld1, yeah I checked everything else and then again like you said. Good thing I’m made a tow hitch for the bike coz now I can load the trailer up with fuel, I don’t think there will be room for anything else…I remember reading on here someone asking about making one, this is what I came up with. It’s agricultural I know but it’s going to get the job done

Attachments

Everything? Everything covers a lot of ground! Did you use a dial indicator and degree wheel to verify TDC mark, ignition timing marks, and valve opening/closing events? If you did, and the ignition coil is getting good power with no significant voltage drop, and carbs are synched and behaving well under the throttle, and the intake running valve lash has been opened up to .006", it might be a good time to start looking for an unmolested cylinder head.

Trqmonster

XS650 New Member

Any chance I could get that from you as well? New to the xs world with a 79 specialI have a PDF of the Mikuni-Sudco tuning manual. Its 19mb so to big to post up here. I can get it to you with an email. Send me a conversation and we can sort out the E-mails.

View attachment 216070View attachment 216071View attachment 216072

Howdy,Any chance I could get that from you as well? New to the xs world with a 79 special

You appear to have VM style carbs on your bike (maybe Mikuni, maybe not). The Sudco Manual may help too, but here's a good discussion of Mikuni VM carbs:

https://www.xs650.com/threads/help-me-id-these-and-can-they-be-tuned-mikunis.6570/

Similar threads

- Replies

- 5

- Views

- 271

- Replies

- 4

- Views

- 582