-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spoking how to.

- Thread starter toglhot

- Start date

Thanks for the write up. I have been lacing my own wheels for quite some time however I left the truing to a person who was good, fast,and reasonably priced. Since moving to Idaho I was forced to start truing my own wheels and several other friends wheels. I have become pretty good at it however it does take some time especially if I use a dial indicator rather than just a pointer. We would like to hear your comments on truing.

Improper torques can be disastrous..

All I'm going to add is that the 36 spoke 16" rears use a different pattern than the larger wheels. I guess you would call it a "cross two", not a "cross three"? .....

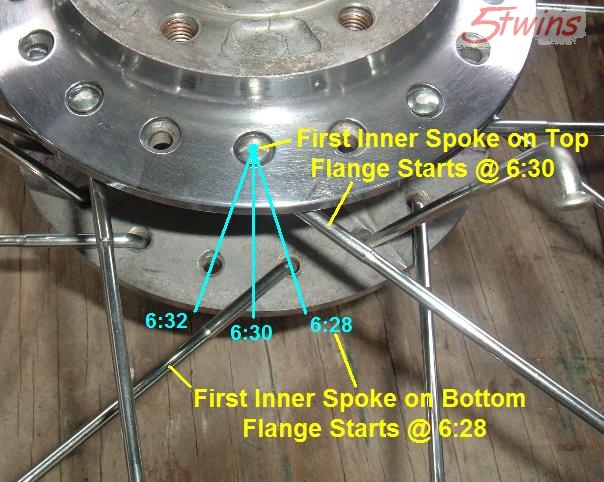

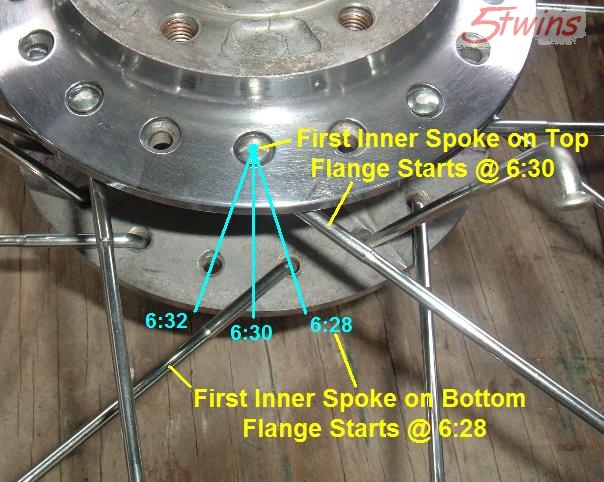

..... and the all important start. Get this wrong and you're doomed, lol .....

..... and the all important start. Get this wrong and you're doomed, lol .....

Improper torques can be disastrous..

View attachment 196639

And look at the size of those spokes. So the question is were they to tight or to loose. I would respect to loose considering they broke loose at the hub probably during a hard brake

Something looks wrong with that picture. That would be a catastrophic failure resulting in much more damage and injury. Other than the wheel, the only damage I see is a crooked headlight.

I understand this are the Motea Fat spokes. Motocross Rims from Brand Manufacturer (motea.com) And I do not know if hard braking was a factor in this failure when it happened, maybe the reason there is less damage.And look at the size of those spokes. So the question is were they to tight or to loose. I would respect to loose considering they broke loose at the hub probably during a hard brake

@willis

Nice write up Toglhot.

79 through 81 SP IIs and 82-83 Heritage Specials had 16" spoke rear wheels 79 were alloy the rest chrome steel. the 82-83 had 48 spokes. in an unusual pattern.

A 21" 64 spoke front.

79 through 81 SP IIs and 82-83 Heritage Specials had 16" spoke rear wheels 79 were alloy the rest chrome steel. the 82-83 had 48 spokes. in an unusual pattern.

A 21" 64 spoke front.

Dave From Maine

XS650 Member

Thank you for the information togolot, its helpful & encouraging ....I was just out to garage unwrapping spokes from Brucannens & setting up some rims for reference photos before disassembly. Hopefully will get them done this month.

I have only spoked a few motorcycle wheels before

They had a note saying try to achieve 80 inch pounds torque, that note was not in previous sets from them.

I can contact them to see how to measure that but as this thread appeared thought I’d ask first before calling them

I have only spoked a few motorcycle wheels before

They had a note saying try to achieve 80 inch pounds torque, that note was not in previous sets from them.

I can contact them to see how to measure that but as this thread appeared thought I’d ask first before calling them

I don't use a torque wrench, just make them tight enough so they "ring" when tapped. Honestly, I don't think you can make them all the same tightness, the rim won't be true then. Some will need to be a bit tighter than others to pull the rim into alignment. This is especially true on a used rim. New straight rims are much easier to true up. My latest, a new 2.15 x 19 (non-flanged) alloy rim on clearance from Mike's and stainless spokes from XS650Direct (they have the best stainless spoke prices). It came out nice and was very easy to true up .....

Thank you for the information togolot, its helpful & encouraging ....I was just out to garage unwrapping spokes from Brucannens & setting up some rims for reference photos before disassembly. Hopefully will get them done this month.

I have only spoked a few motorcycle wheels before

They had a note saying try to achieve 80 inch pounds torque, that note was not in previous sets from them.

I can contact them to see how to measure that but as this thread appeared thought I’d ask first before calling them

Interesting note from Buchanan's. I also had a note that had a very high torque value. They were Z1900 stainless spokes. The problem was we just had them do a set of the same wheels the previous year and they came back with a tag stating a torque of 35-40 on the rear and 40-45 on the front. Now that was about 75% lower torque than what they were suggesting with the current set. I would give them a call to verify.

there's a Utube by a buch tech; no torque wrench, no dial indicator, he sez; you are overthinking this.

Someone gave me a basic lesson in assembling wheels and the main gist of it was "install inner first then outers, inners adjust radial, outers adjust side/side"

From that I did my first wheels back in the 70's with a stand I made from a 12" long piece of 2x6 as a base, a piece of 1x3 with "V" notches cut in the top using drywall screws attaching one to either side.

I used a Crayon held against the side of one of the legs as a marker to gage runout and would have to wipe off the marks many times before complete. Going back and forth between radial and side/side runout. Tension was gaged by sound when I would tap them with the spoke wrench

Probably did half dozen wheels with that stand using an axle laying in the notches, also used it for balancing after.

On wheels I'm going to rebuild with new spokes but same pattern I generally make a mark with a marker or scribe on the hub along the edge of a couple of the spokes. Helps get the spacing right.

From that I did my first wheels back in the 70's with a stand I made from a 12" long piece of 2x6 as a base, a piece of 1x3 with "V" notches cut in the top using drywall screws attaching one to either side.

I used a Crayon held against the side of one of the legs as a marker to gage runout and would have to wipe off the marks many times before complete. Going back and forth between radial and side/side runout. Tension was gaged by sound when I would tap them with the spoke wrench

Probably did half dozen wheels with that stand using an axle laying in the notches, also used it for balancing after.

On wheels I'm going to rebuild with new spokes but same pattern I generally make a mark with a marker or scribe on the hub along the edge of a couple of the spokes. Helps get the spacing right.

Went to see an oldtimer for some advice over the weekend.

I just got more confused.

I just got more confused.