-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff my dog says; on second thought I'll just build a race car

- Thread starter NashGTI

- Start date

Way back when you started building the frame the car looked over-dimensioned in more than just one direction - probably due to camera lens distortion. Seeing it in the last video with you taking a sneak ride suddenly made everything look the correct proportion. You should be very pleased with your progress...

At the time of the dash and firewall bars nearly everyone questioned their height. Hell I did myself seeing them with just the bare tube frame beginning. As cliche as it sounds though I just kept thinking trust the process. I knew I had drawn everything out and it looked OK vertically in the drawings.Way back when you started building the frame the car looked over-dimensioned in more than just one direction - probably due to camera lens distortion. Seeing it in the last video with you taking a sneak ride suddenly made everything look the correct proportion. You should be very pleased with your progress...

The overall length is still something that I believe looks slightly ungainly, that's due to the dimensions of the engine and trans and my personal requirent for serviceability. Seeing it side by side nose on with the Ford really makes it look small, while seeing them stacked from the side makes it look enormously long because of perspective. I need a better angle there, or to get a picture of it under another car on the lift to properly show that.

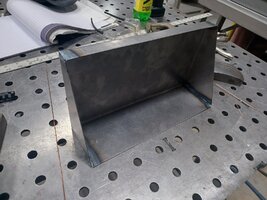

How did you compute the size of the airbox and filter to allow for the blower?

Compute?How did you compute the size of the airbox and filter to allow for the blower?

It's a Ford 7.3 Powerstroke air filter and those were rated 200hp 500ft-lbs which is almost certainly more airflow requirement than I need. Plus the side fits nicely in that spot above and behind the valve cover. It may sound stupid for reasoning but I'm betting it works.

Although if I were to be asked specifics (and I'm just doing this) K and N has test data for their filters on their website. So this filter shows a clean flow rate of 579cfm and 1.5inH2O. My plan is to use a 600cfm carburetor, but the engine doesn't hit 100 percent volumetric efficiency, I don't have my computer in front of me here at work but I want to say it's peak was in the 91 percent range? Actually I think the Desktop Dyno program even will give you flow rate, but doing the admittedly incorrect math 91 percent of 600 is 546.

Again grain of salt that, but it all sounds good and makes it look like I know what I'm doing.

<iframe src="https://giphy.com/embed/n8SkNR77udWlG" width="480" height="333" frameBorder="0" class="giphy-embed" allowFullScreen></iframe><p><a href="">via GIPHY</a></p>

It was mostly slinging BS anyway because that's not how volumetric efficiency works in the first place, but I was off the dyno table shows just over 100 percent.

Last edited:

NashGTI,

I have been looking closely at your car and have clipped an image out of the video. This is free from lens distortion as the car is far from the camera. I don't know about you but I think the dimensions look very very nice...

I have been looking closely at your car and have clipped an image out of the video. This is free from lens distortion as the car is far from the camera. I don't know about you but I think the dimensions look very very nice...

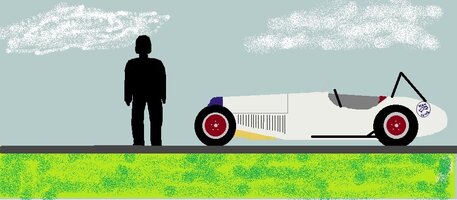

It's not bad and I still enjoy looking at it, but I think it needs two things to be really nice. One I think it needs six inches taken out between the wheels and two, it needs larger diameter wheels/tires. I need to get the boat tail on the back too before the true dimensions will be apparent so think something in the order of another foot behind the furthest rear part at the current time.NashGTI,

I have been looking closely at your car and have clipped an image out of the video. This is free from lens distortion as the car is far from the camera. I don't know about you but I think the dimensions look very very nice...

View attachment 223544

I still see this in my head looking at the car now

Which that rear suspension setup is clearly out of date now, but the scale should be real close and it makes the car look overly long to my eye.

Math is fun, and I was thinking math things at work this afternoon.

Let's say I averaged 8 hours a week from July to July working on the car. It was probably more than that but if you account for a few weeks off in there we'll go 50 weeks of 8 hours a week for 400 hours. Single the beginning of July this year I've done about 25 hours a week for 8 weeks, so that's another 200 hours. The week of Christmas and New Years last year I took vacation to work on the car, so another 50 hours there. Then we have the time spent designing which is.....100 hours maybe? Again don't really know but you could lump the time working on the transfer case deal and rear axle in there too and 100 hours is probably low but we'll work with it. That's 750 hours working on the car in the last 20 months or so. Without going into too much detail my pay rate for overtime is a little under 50 an hour but for simplicity's sake we'll use that to go the lost revenue cost of working on my car for me is roughly $37,500. Plus the amount I've paid out for parts of around $15,000.

So if anyone is curious what something like this costs there is a ballpark number so far for the project of a little over fifty thousand dollars. Maybe math isn't so fun....

Let's say I averaged 8 hours a week from July to July working on the car. It was probably more than that but if you account for a few weeks off in there we'll go 50 weeks of 8 hours a week for 400 hours. Single the beginning of July this year I've done about 25 hours a week for 8 weeks, so that's another 200 hours. The week of Christmas and New Years last year I took vacation to work on the car, so another 50 hours there. Then we have the time spent designing which is.....100 hours maybe? Again don't really know but you could lump the time working on the transfer case deal and rear axle in there too and 100 hours is probably low but we'll work with it. That's 750 hours working on the car in the last 20 months or so. Without going into too much detail my pay rate for overtime is a little under 50 an hour but for simplicity's sake we'll use that to go the lost revenue cost of working on my car for me is roughly $37,500. Plus the amount I've paid out for parts of around $15,000.

So if anyone is curious what something like this costs there is a ballpark number so far for the project of a little over fifty thousand dollars. Maybe math isn't so fun....

Just imagine how much you would have spent if you played that much golf! Do some more math. Perhaps your hobby isn't so expensive after all.So if anyone is curious what something like this costs there is a ballpark number so far for the project of a little over fifty thousand dollars.

Plus the skills and knowledge you have gained from this project have great value if not easy to calculate.

Back when I started working in the shop at the quarry the boss who started that shop encouraged us to bring in project's from home to work on after hours and even made a point to point them out to visitors.

But that was back in the old days before the bigwigs of the company got all nervous about liability and possible theft of company assets. Yea! like the handful of 3/8 bolts or the few scraps of angle iron was going to bankrupt a multi-million dollar company!

For example, He figured the time one of us spent using the valve grinding tools on our project helped us do a faster and better job the next time we needed to do the valves in a Mack engine.

Back when I started working in the shop at the quarry the boss who started that shop encouraged us to bring in project's from home to work on after hours and even made a point to point them out to visitors.

But that was back in the old days before the bigwigs of the company got all nervous about liability and possible theft of company assets. Yea! like the handful of 3/8 bolts or the few scraps of angle iron was going to bankrupt a multi-million dollar company!

For example, He figured the time one of us spent using the valve grinding tools on our project helped us do a faster and better job the next time we needed to do the valves in a Mack engine.

Apparently I need a better camera mount

And to learn how to use the camera better

And to actually use the external mic that came with it

I got this lovely still photo accidentally though so there is that.

And to learn how to use the camera better

And to actually use the external mic that came with it

I got this lovely still photo accidentally though so there is that.

Last edited:

First on car video and it isn't great. I didn't use the external mic and the camera mount sucks and the camera ended up pointed at the sky. Also it didn't end the video when I wanted to end the video so there is pointless footage at the end. The camera came with a remote trigger but I'm not sure how to use it yet. At least it's something though right?

More importantly I actually pushed the car through the downhill left hand turn coming back hard enough to feel the rear tires begin to JUST start to slide a little and it felt glorious. I was really hoping that having the air filter hooked up would richen the engine up but in hindsight there is so much available airflow compared to carb size with that filter and the little one barrel Holley on the engine right now there was no hope of it. So the car is still borderline catastrophically lean under throttle. Also you can hear me grind the hell out of the non-syncro first gear, I'm not a proficient double clutch artist yet.

More importantly I actually pushed the car through the downhill left hand turn coming back hard enough to feel the rear tires begin to JUST start to slide a little and it felt glorious. I was really hoping that having the air filter hooked up would richen the engine up but in hindsight there is so much available airflow compared to carb size with that filter and the little one barrel Holley on the engine right now there was no hope of it. So the car is still borderline catastrophically lean under throttle. Also you can hear me grind the hell out of the non-syncro first gear, I'm not a proficient double clutch artist yet.

You were blessed with a lovely head. Lucky you!First on car video and it isn't great.

Even if you quit now, you've accomplished far more than I could on a project like that.

You were blessed with a lovely head. Lucky you!

Ummm....thanks?

So I bit the bullet and took the single barrel Holley off and opened the float bowl. Turns out it uses the same style jets as the Hollley carbs we are all used to so I was able to bump up a few jets sizes (big changes get results) plus the float was definitely low so I raised it. I couldn't find a definitive number for a setting as everyone just says use the tool but based upon pictures I set it to parallel and that should at least be better. The question now, are those things enough? I didn't get any new gaskets or even try to really clean anything so it's entirely possible to issue is a malfunctioning power valve circuit. Or maybe it's a dead accelerator pump? Maybe it's all the above, but without new gaskets I burnt the boats and used RTV to get the thing water tight again.

Oh yeah, it's been storming the for last three hours so no testing it tonight.

Similar threads

- Replies

- 22

- Views

- 3K