On the multi-fuse Special models, there really is no good readily available connection point inside the headlight for the power lead of a voltmeter. Any spot you choose has already gone through multiple splits or connections and at least two fuses. This usually results in a meter reading several tenths of a volt lower than at the battery. There is a good connection point, the brown wire coming out of the ignition switch. This is the only spot you'll find switched power that only goes through one (the main) fuse. But, there is no way to connect here unless you add it, so here's how I do it ....

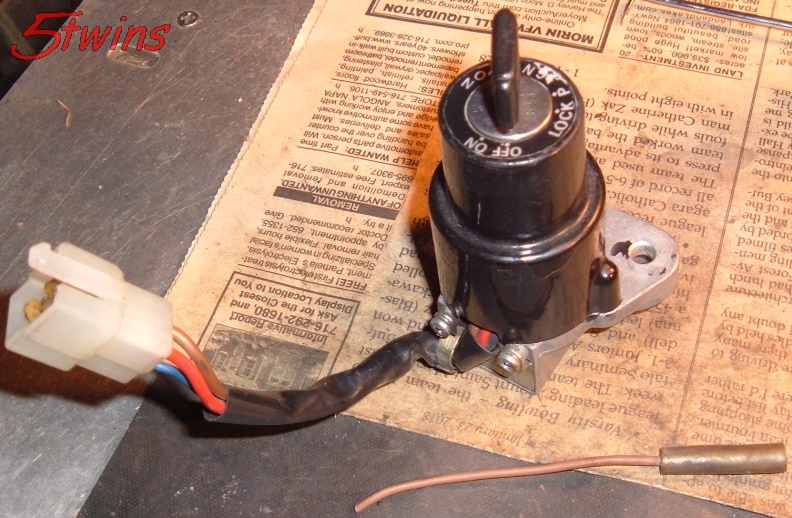

First, the candidate for this, the original ignition switch off my buddy's 1980 SPII. Also pictured is the little pigtail I'll be adding, clipped from an old wiring harness .....

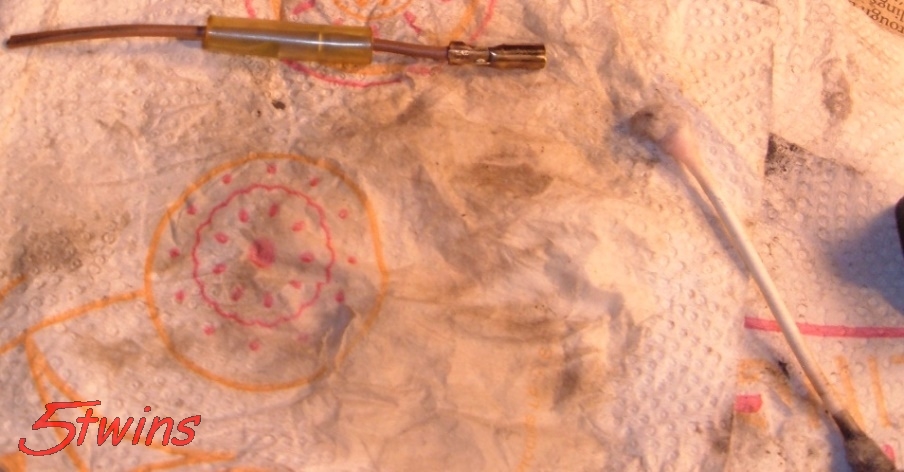

As you can see, the "new" wire is pretty grungy and will require a good cleaning .....

For this, I use a product called the Tannery. This is wonderful stuff that's been around for many, many years. It's excellent for cleaning plastics, rubber, vinyl, and leather. After spraying and wiping down the wire itself .....

..... I spray a little in a plastic cup and scrub the wire and bullet connector cover really clean using Q-tips. As you can see by how dirty the Q-tip got, it does a great job .....

The bullet connector is polished clean with a wire wheel in a Dremel and then coated with dielectric grease .....

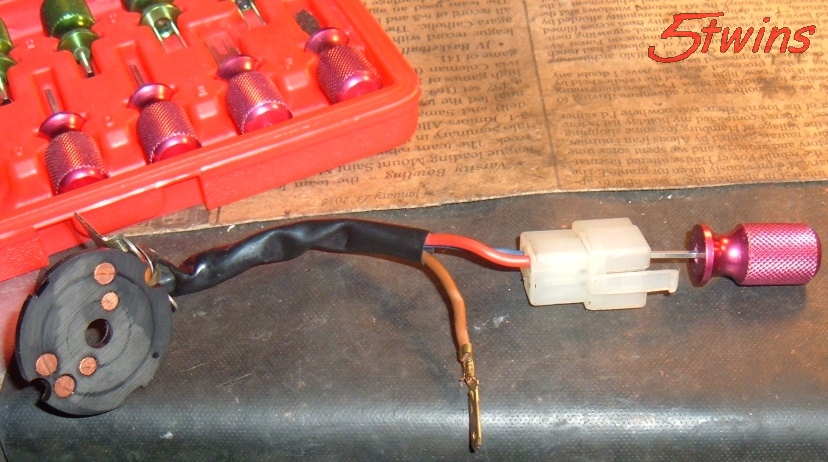

Then, after the switch contact plate is removed, I pull all the crimps out of the plug .....

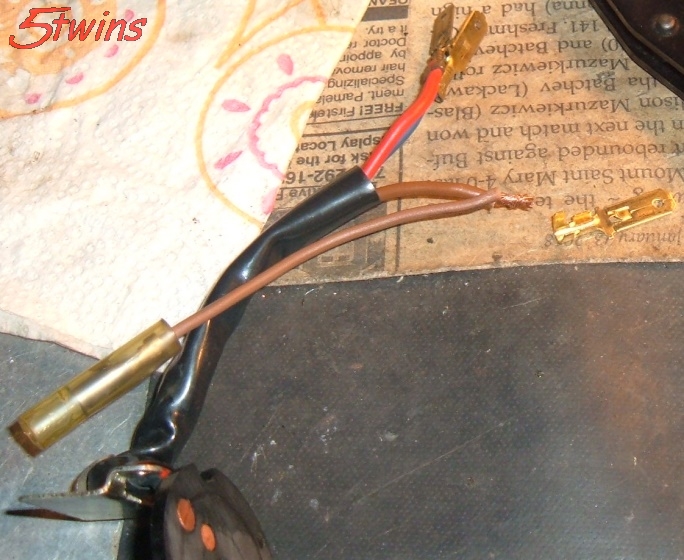

The original crimp on the brown wire is cut off and the "new" pigtail wire is added .....

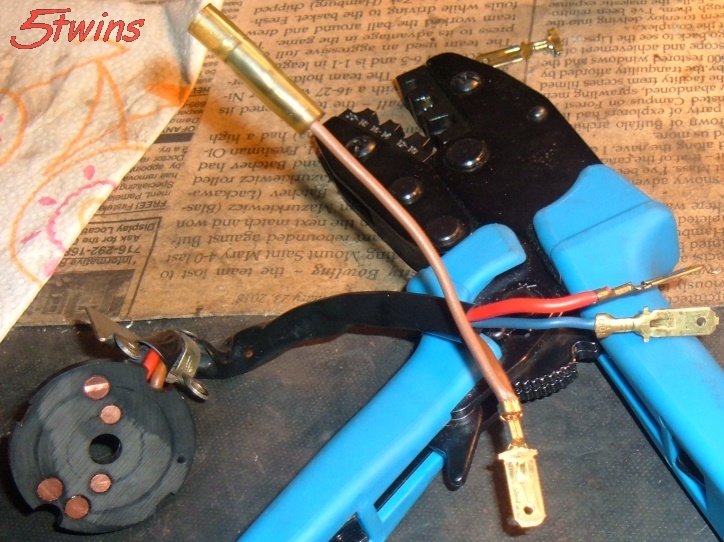

Then following an XSLeo tip, the wire end is brushed with some dielectric grease becore installing the crimp on it .....

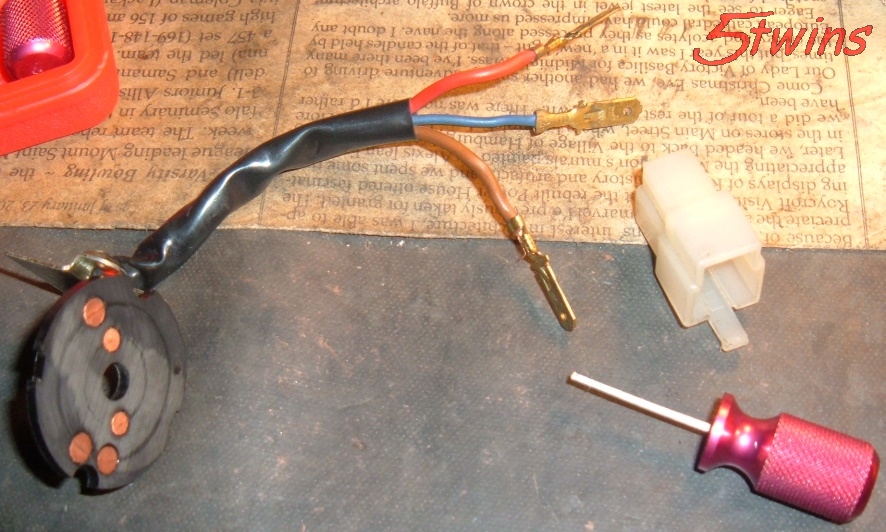

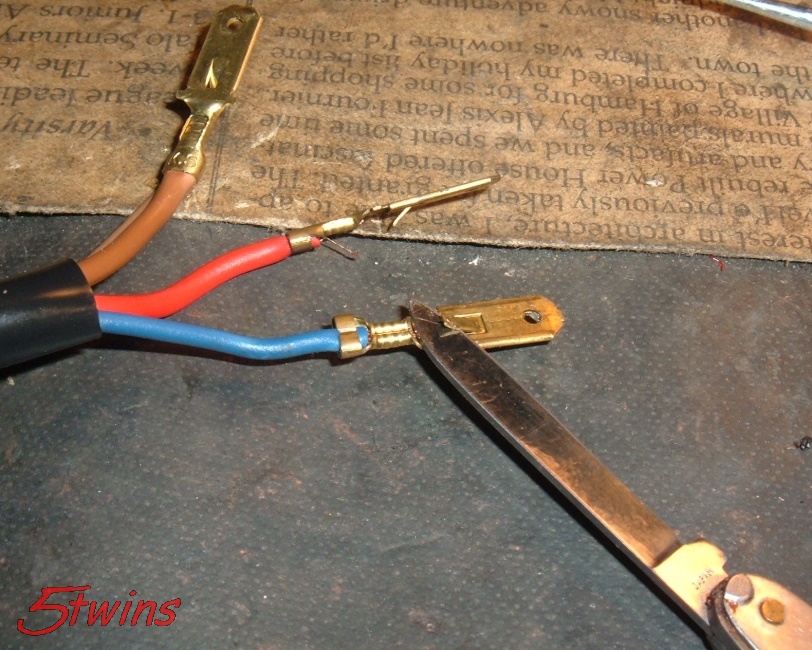

Now, before inserting all the crimps back into the plastic plug housing, the locking tabs need to be bent back up. The removal process flattens them down .....

More dielectric grease .....

And the finished product .....

First, the candidate for this, the original ignition switch off my buddy's 1980 SPII. Also pictured is the little pigtail I'll be adding, clipped from an old wiring harness .....

As you can see, the "new" wire is pretty grungy and will require a good cleaning .....

For this, I use a product called the Tannery. This is wonderful stuff that's been around for many, many years. It's excellent for cleaning plastics, rubber, vinyl, and leather. After spraying and wiping down the wire itself .....

..... I spray a little in a plastic cup and scrub the wire and bullet connector cover really clean using Q-tips. As you can see by how dirty the Q-tip got, it does a great job .....

The bullet connector is polished clean with a wire wheel in a Dremel and then coated with dielectric grease .....

Then, after the switch contact plate is removed, I pull all the crimps out of the plug .....

The original crimp on the brown wire is cut off and the "new" pigtail wire is added .....

Then following an XSLeo tip, the wire end is brushed with some dielectric grease becore installing the crimp on it .....

Now, before inserting all the crimps back into the plastic plug housing, the locking tabs need to be bent back up. The removal process flattens them down .....

More dielectric grease .....

And the finished product .....