HaHa, I hadn't noticed that. Funny though it didn't seem to bother him at the time.In that last photo I would imagine that adjustable clamp to be a little uncomfortable...

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff my dog says; on second thought I'll just build a race car

- Thread starter NashGTI

- Start date

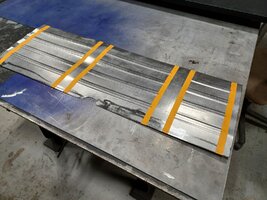

Did a lot of things today. Mounted the brake proportioning valve, fuel pump, and fuel pressure regulator. Ran the hard lines for fuel anchoring them on studs welded to the chassis. Then I got a good start on the drivers floor pan. I've got it fitted so I'll bead roll it some for more strength Monday after work.

Awesome job on this project.

Thanks for sharing it with us.

Thanks for sharing it with us.

Worked today on the firewall and off side floor panel thats more of a lower cover than it is a floor. I'm trying to decide if I want to bead roll something into that panel or just leave it flat. With it just being a panel to hold electrics it doesn't necessarily need any strengthening but I'd probably look better visually with something like the driver's floor.

Massive project!

I suggest you bead roll it, then you will have no regrets later on...

I suggest you bead roll it, then you will have no regrets later on...

I think I'd enjoy tin-bending but every time I go looking for tools, even the used stuff is WAY out of my price range.

I'm lucky enough to have access to it all through work. No way I'd have half the knowledge and skills I do if it weren't for getting the opportunity to mechanic there and screw around after hours. Simple lines like these, or even geometric shapes are pretty simple with the bead roller we have. Some of the fancy stuff the people who are legitimately good at it are able to do blow my mind.

Also great that the place you work lets you use the tools on your time off. The place I worked did not have a lot of fancy tools but as a shop that did heavy equipment repairs I did have access for years to all kinds of things like welders presses and parts cleaning equipment.

For the first say 20 years it was allowed and even encouraged for the guys in the shop to make use of these things for private projects. Then as we went through various corporate mergers it got to the point where using anything of the company's tools or facilities for personal use was thought of as theft.

For the first say 20 years it was allowed and even encouraged for the guys in the shop to make use of these things for private projects. Then as we went through various corporate mergers it got to the point where using anything of the company's tools or facilities for personal use was thought of as theft.

Floors welded in this morning, went ahead and just MIGed them.

My boss is great in that respect (amongst others). The entire process of building my XS he never asked for a dime whenever I brought it up, said it was basically a training exercise the way he saw it. I actually asked him about some sheets of 20ga last night and he said just take them.

I'll say too, the guys I work with who's shop I'm building the car at have been great. I'm giving them some cash for stuff but it's nowhere near what I've actually used.

My boss is great in that respect (amongst others). The entire process of building my XS he never asked for a dime whenever I brought it up, said it was basically a training exercise the way he saw it. I actually asked him about some sheets of 20ga last night and he said just take them.

I'll say too, the guys I work with who's shop I'm building the car at have been great. I'm giving them some cash for stuff but it's nowhere near what I've actually used.

Attachments

to mechanic there and screw around after hours.

Considering what it appears your company does, if I ran the business, I would certainly allow what you're doing after hours. You're honing your skills and developing new ones. You're improving your talent at no significant cost to the operation. Have at it!Also great that the place you work lets you use the tools on your time off.

That was just the attitude my first boss had, any time one of us young guys (yea that was some years back when I was considered a young guy) wanted to spend some time after working hours to work on a personal project. He would even make it a point to show visitors what us "kids" were doing after hours. He thought of it as more or less free training for the company!Considering what it appears your company does, if I ran the business, I would certainly allow what you're doing after hours. You're honing your skills and developing new ones. You're improving your talent at no significant cost to the operation. Have at it!

But like I said as the company merged and got taken over by ever bigger companies attitudes changed to the point they were more afraid someone might get hurt on company property or maybe use up half a dozen 7018 welding rods and that was going to eat into the profits of a large multi-national companies bottom line!

Also as I went to put the toe board in fitting it I noticed that I had goofed the bead rolling up. I remembered the measurement three inches and went off that since I was across the street from the car when I did the bead rolling. I was only half right though as the flange die lines were three inches from each other, but the center bead was only two inches from the flange lines on the top firewall piece.

So hurray for trying to do things two different buildings nearly every line on the toe board is an inch offset from the lines on the top of firewall piece.

So hurray for trying to do things two different buildings nearly every line on the toe board is an inch offset from the lines on the top of firewall piece.

He would even make it a point to show visitors what us "kids" were doing after hours.

I keep thinking with all the TicFace stuff my work does that it would be greatly beneficial to show what the employees are doing with their own time and money. Show that we aren't just there for a paycheck but truly are car nuts and love what we do.

They clearly don't agree with that line of thinking though as they specifically avoid showing any of the employee projects on the shop social media.

Don't worry, it all appears symmetric so looks deliberate...

I was speaking on it elsewhere this morning. What I should have done was gone with a completely different design for the toe board. Friday when I was doing the bead rolling I had thought about just doing a three box design and instead elected to try and copy the panel above. With the end result where it is not easy really easy to look back and say I should've just done the boxes. Looking deeper than the lines simply not lining up though, there was never any chance to get things to completely line up because the toe board space is just fundamentally different as there was no way to keep the outermost line. Additionally to that though, the lines on the toe board also don't match the lines on the floor board.Don't worry, it all appears symmetric so looks deliberate...

In the end though, there will be a lot of stuff in the way of the firewall with the air box, carburetor, throttle linkage, brake and clutch lines, and battery cables all having to be directly in front of or through it.

Similar threads

- Replies

- 22

- Views

- 3K