Interesting, it appears many of the earlier cams are installed incorrectly. Not surprising though, you have a 50-50 chance of getting it right, unless you're aware of the significance of the dimple, which it appears nobody was until 2M's recent discovery. It wouldn't surprise me if many came assembled wrong from the factory.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

650 Rear Drum Brake Plates

- Thread starter 5twins

- Start date

Yes, a 50/50 and I looked at what I did to my 79F with the old used but very clean original shoes and ofcourse I assembled it dimple back.. So, is it worth going to the trouble to turn it around ? Who knows yet.Not surprising though, you have a 50-50 chance of getting it right, unless you're aware of the significance of the dimple,

Very Good reading this thread !

Thank you, Randy

The wonkiness continues.

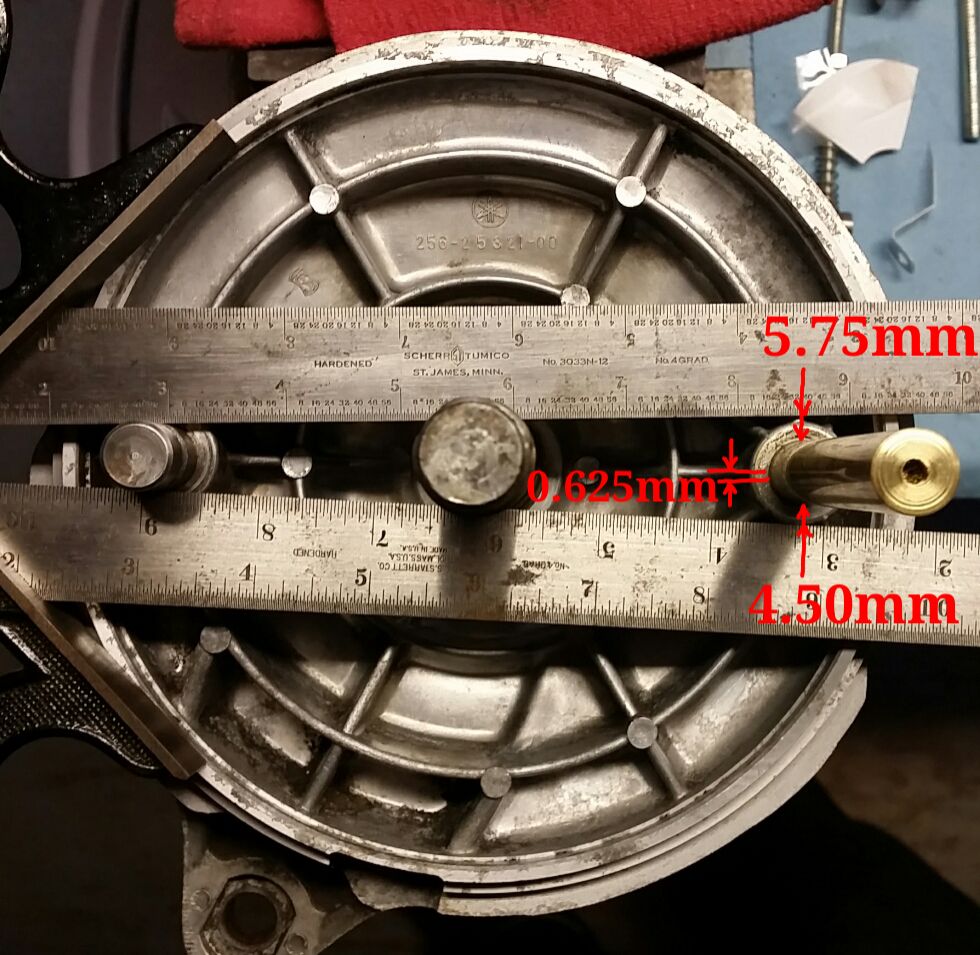

This is getting really strange. I wanted to see if the borehole for the brake cam might have any off-center displacement, to account for the slight offset in the brake cam. Using my spare backing plate (from a '73 TX), I laid 2 straight edges against the anchor post and axle, and measured the gaps between those straight edges and a 14mm brass shaft fitted into the brake cam bore.

Oh, good grief. The cam's borehole is 0.625mm (0.025") below center!

The cam itself has a bit of an offset, about 0.075mm, towards the Leading shoe, but that's not enuff to correct the hole's offset. I wonder if this exists in all backing plates, and why.

This would certainly push the Trailing shoe into contact long before the Leading shoe ever touches. No wonder our rear brakes are pathetic. It would take a month of Sunday's to bed these in. If considering a brake shoe arc job, best done as installed on the backing plate, with the cam properly fitted.

The backing plate, cam, and shoe assembly I recently installed in my XS1B didn't show any offsets, and I expected it to perform up to par...

This is getting really strange. I wanted to see if the borehole for the brake cam might have any off-center displacement, to account for the slight offset in the brake cam. Using my spare backing plate (from a '73 TX), I laid 2 straight edges against the anchor post and axle, and measured the gaps between those straight edges and a 14mm brass shaft fitted into the brake cam bore.

Oh, good grief. The cam's borehole is 0.625mm (0.025") below center!

The cam itself has a bit of an offset, about 0.075mm, towards the Leading shoe, but that's not enuff to correct the hole's offset. I wonder if this exists in all backing plates, and why.

This would certainly push the Trailing shoe into contact long before the Leading shoe ever touches. No wonder our rear brakes are pathetic. It would take a month of Sunday's to bed these in. If considering a brake shoe arc job, best done as installed on the backing plate, with the cam properly fitted.

The backing plate, cam, and shoe assembly I recently installed in my XS1B didn't show any offsets, and I expected it to perform up to par...

Last edited:

I repeat:

New Vesrah VB-225 shoes, cam aligned, shoe arcs concentric with the axle.

Unbelievable!

First time I applied the rear brakes, nothing.

Like they were made of ice.

Rode about 5 miles of speed up, brake, speed up, brake, repeatedly.

They finally started to grab, but not as well as the old shoes.

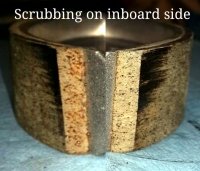

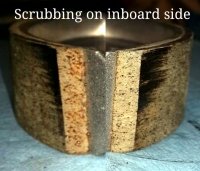

A theory, maybe my drum is tapered. Another closer look at the scuffing pattern of Randy's oversized shoes shows that my drum may indeed be slightly tapered, narrower to the inside.

Dunno about these new shoes. Maybe modern friction materials.

I'm continuing to bed them in.

But, now they're doing the occasional 'squeel' during application...

...The backing plate, cam, and shoe assembly I recently installed in my XS1B didn't show any offsets, and I expected it to perform up to par...

New Vesrah VB-225 shoes, cam aligned, shoe arcs concentric with the axle.

Unbelievable!

First time I applied the rear brakes, nothing.

Like they were made of ice.

Rode about 5 miles of speed up, brake, speed up, brake, repeatedly.

They finally started to grab, but not as well as the old shoes.

A theory, maybe my drum is tapered. Another closer look at the scuffing pattern of Randy's oversized shoes shows that my drum may indeed be slightly tapered, narrower to the inside.

Dunno about these new shoes. Maybe modern friction materials.

I'm continuing to bed them in.

But, now they're doing the occasional 'squeel' during application...

Getting Very interesting ! Sure is nice to read and learn all of this. It seems I personally dodged a bullet by passing the Vesrah shoes on to you to experiment with and we all are gaining in knowledge. Your investigation of the brakes is a huge benefit ! Thanks again, -RandyDunno about these new shoes. Maybe modern friction materials.

Well, I went ahead and changed the cam around on my TX750 brake plate. Braking is better now than before, hopefully will continue to improve as the shoes bed in more and adapt themselves to the correct cam installation. I rode the thing for years literally with the cam in there wrong so I expect some bedding in time will be required. I also have a couple more sets of shoes I can try, which I probably will when the wheel needs to come off next time.

I have some loose brake plates (XS1, '77, '78, '81+). I'll have to check that cam hole location on them.

I have some loose brake plates (XS1, '77, '78, '81+). I'll have to check that cam hole location on them.

Got me thinking. Checked my XS650 and TX750, both cams in the right way. My XS rear brake is not that good, but the TX rear brake is excellent. I know the TX750 brake is bigger but from my hazy recollection my first XS had a really good rear brake.

Given that the XS has been restored, and the TX has the original linings, I think the XS has after market shoes, I’ll have to wait until it needs a new rear tyre before I can see, unless I get a puncture. Touch wood.

I do know from experience if you don’t have a chamfer on the leading edge it makes the brake very grabby.

Given that the XS has been restored, and the TX has the original linings, I think the XS has after market shoes, I’ll have to wait until it needs a new rear tyre before I can see, unless I get a puncture. Touch wood.

I do know from experience if you don’t have a chamfer on the leading edge it makes the brake very grabby.

Reviewing previously seen measurement methods of the brake arcs, brake cams, pivots too, and lately the brake plate cam bore, It is not clearly confirmed yet that the brake pad horizontal plane and the corresponding planes of the brake cam and pivot are all parallel to each other.A theory, maybe my drum is tapered.

Perhaps there is error in the shoes (cam flats or pivot surfaces) or in the backing plate features, Such as the pivot stay and cam bore not being parallel to each other ?

This condition could also force the shoes to spread "crooked".

More measuring ? Lol !

Hmm grabbed off the shelf; hub was de-cleared drum hand stoned, tag says assembly had 10K miles. Since shoes are new, assume the shaft has been removed polished lubed reinstalled in a random orientation. Shoes, cruisin image or mikes or?? note sloppy fit at pivot, This has the "early style" non symmetric cam profile.

This is just plate on axle with some grease, about .010" of slop at gauge possible by rocking plate on axle, limit to limit. These new shoes appear to have been ground, turned to a radius.

2M I'm your tool, take a look, what would you like me to do next? No fair just telling me to F off.........

This is just plate on axle with some grease, about .010" of slop at gauge possible by rocking plate on axle, limit to limit. These new shoes appear to have been ground, turned to a radius.

2M I'm your tool, take a look, what would you like me to do next? No fair just telling me to F off.........

Last edited:

I would be happy with those readings, I think the limiting factor is the shoes being captivated at one end the radius on the shoes has to be near perfect for the brake to be efficient. Triumph rears have floating shoes, so they can jiggle themselves to match the drum.Hmm grabbed off the shelf; hub was de-cleared drum hand stoned, tag says assembly had 10K miles. Since shoes are new, assume the shaft has been removed polished lubed reinstalled in a random orientation. Shoes, cruisin image or mikes or?? note sloppy fit at pivot, This has the "early style" non symmetric cam profile.

View attachment 137381 View attachment 137382 View attachment 137383 View attachment 137384 View attachment 137385 View attachment 137386 View attachment 137387 View attachment 137388

This is just plate on axle with some grease, about .010" of slop at gauge possible by rocking plate on axle, limit to limit. These new shoes appear to have been ground, turned to a radius.

2M I'm your tool, take a look, what would you like me to do next? No fair just telling me to F off.........

Ggggary, great pics and vids. Yup, them's the budget SOK shoes (MikesXS and CruzinImage), with the lousy anchor post fitment. You found an increase in radius at the area near the cam.

It takes a lathe with at least a 12" swing to really do this correctly. Glad you can chuck it up and check this. Might want to try a re-arc job. New shoes are supposedly arched at 179mm, but the drum is 180mm. The idea would be to preset and lock down the cam to at least 10°, then turn the shoes to the target drum diameter of 180mm. Your lathe is the best method.

I was thinkin' on making a drum sander system on my drill press, like this.

But, if the shoes are already arced to 179mm, the cam may need to be rotated even more, maybe 15°. And all you'll end up with is the equivalent of worn, bedded-in shoes. Maybe not a bad thing.

Again, the 12" lathe is the best for this re-arcing. Need a way to solidly clamp it in the chuck, using an axle, spacers, and nut. Found some thick wall 20mm ID steel spacer stock.

https://rover.ebay.com/rover/0/0/0?mpre=https://www.ebay.com/ulk/itm/112876920529

I received one, 32mm OD, 20mm ID, 7"long. Precision stuff.

That one pic shows using tiewrap to hold the brake lever arm. *ooof*. A bent piece of allthread is more solid, simple Justa thought.

It takes a lathe with at least a 12" swing to really do this correctly. Glad you can chuck it up and check this. Might want to try a re-arc job. New shoes are supposedly arched at 179mm, but the drum is 180mm. The idea would be to preset and lock down the cam to at least 10°, then turn the shoes to the target drum diameter of 180mm. Your lathe is the best method.

I was thinkin' on making a drum sander system on my drill press, like this.

But, if the shoes are already arced to 179mm, the cam may need to be rotated even more, maybe 15°. And all you'll end up with is the equivalent of worn, bedded-in shoes. Maybe not a bad thing.

Again, the 12" lathe is the best for this re-arcing. Need a way to solidly clamp it in the chuck, using an axle, spacers, and nut. Found some thick wall 20mm ID steel spacer stock.

https://rover.ebay.com/rover/0/0/0?mpre=https://www.ebay.com/ulk/itm/112876920529

I received one, 32mm OD, 20mm ID, 7"long. Precision stuff.

That one pic shows using tiewrap to hold the brake lever arm. *ooof*. A bent piece of allthread is more solid, simple Justa thought.

I think most of us are just going to have to rely on the "foot lathe" for this (ride the bike, step on the brake), lol. I do feel my 750 brake is much stronger now with the cam installed correctly. I can't wait to "fix" and try some of my 650 ones. I serviced the brake plate on my '83 last summer. It was in dire need, squealing and squawking when applied. The shoes in there, originals probably, are quite thin and about done for. It'll get some new Vesrah shoes most likely. Two of my spare plates have good stock shoes still, another has none and will most likely get the other set of Vesrah shoes I have. I also have a set of Ferodo shoes from 3m to try. He claims they're the best, but he says the same about his front pads, and I wasn't real impressed with them compared to stock ones. I also have and have tried Ferodo TX750 shoes from him. Again, no different than stock that I could tell, but we'll see now that the cam install is corrected.

An interesting observation. Bike on centerstand, stoop down alongside the bike's right side, watch the rear wheel while pressing down on the brake pedal.

On mine, with the new shoes, you can just see the rear wheel rotate backwards a bit with each press of the brake pedal. That means that the bottom shoe is contacting first, at the cam, pulling down on the hub. I'm thinking that when that wheel rotation discontinues, then both shoes are making that initial contact...

On mine, with the new shoes, you can just see the rear wheel rotate backwards a bit with each press of the brake pedal. That means that the bottom shoe is contacting first, at the cam, pulling down on the hub. I'm thinking that when that wheel rotation discontinues, then both shoes are making that initial contact...

2m, I wus thinking of turning a mandrel out of a bolt or such to clean up the pivot on the aftermarket shoes. Machine it to match the pivot pin on the brake plate, cut some angled slots with the cut off wheel in the dremel so it will act as a cutter. Figured I can chuck the mandrel /cutter in the lathe, clamp a shoe to the tool post and feed it in. See any holes in that plan?

Warning; kind of a rant, cautionary tale follows;

Pretty interested in all this, mainly cuz I got drum fronts to do "some time", and I am a lot more concerned about front brake performance compared to rear, which honestly I don't use that much, I mainly ride bikes with fronts that are quite capable of completely unloading the rear wheel. My take is that unless one is constantly practicing extreme stops the odds of increasing the stopping distance with a rear wheel skid are higher than decreasing it with the small proportion rear brakes add to the equation. Especially if down shifting is added in. In fairness if the shortest possible stopping distance is really needed (for me a deer crossing is the typical scenario) it's clutch in and F being in the correct gear. Hint; practice hard stops on your bike! It's a biggy for me with a long winter lay up (rusty skills) and the variety of bikes I ride with vastly different brakes. Add to it we are mostly spoiled by driving ABS equipped 4 wheelers, just stomp the pedal let the computer do the work....

Example; on the way back from Madison, Royal Star cruiser, (the road couch) Friday, curvy hilly back road, oncoming car and pick up truck, JUST as they were closing with me, near as I can tell the car "brake checked" the tailgating pick up. There was a shit ton of smoke, squealing tires and slewing vehicles coming right at me. Let me tell you I was on the brakes and checking my ditch for an escape path. Fortunately they mostly stayed on their side of the road. I think the truck did hit the car. Man there are idiots everywhere. Reviewing the situation, what I did, what else I might have done, I was damned glad I didn't have a cage on MY rear bumper. I'm pretty big on not letting that happen, but was basically too busy to check my mirrors.... I was also glad I had done a couple of hard stops earlier in the ride, First time out on this bike this season! When I first got this bike I heavily modified the front brakes so full stopping authority at reasonable lever pressure was available, the stock brakes were REALLY pathetic. Different calipers, SS lines, smaller MC, front tire that better matched the rim width than the stock balloon. Note; on this 850 pound low slung bike the rear brake does contribute quite a bit to stopping.

Warning; kind of a rant, cautionary tale follows;

Pretty interested in all this, mainly cuz I got drum fronts to do "some time", and I am a lot more concerned about front brake performance compared to rear, which honestly I don't use that much, I mainly ride bikes with fronts that are quite capable of completely unloading the rear wheel. My take is that unless one is constantly practicing extreme stops the odds of increasing the stopping distance with a rear wheel skid are higher than decreasing it with the small proportion rear brakes add to the equation. Especially if down shifting is added in. In fairness if the shortest possible stopping distance is really needed (for me a deer crossing is the typical scenario) it's clutch in and F being in the correct gear. Hint; practice hard stops on your bike! It's a biggy for me with a long winter lay up (rusty skills) and the variety of bikes I ride with vastly different brakes. Add to it we are mostly spoiled by driving ABS equipped 4 wheelers, just stomp the pedal let the computer do the work....

Example; on the way back from Madison, Royal Star cruiser, (the road couch) Friday, curvy hilly back road, oncoming car and pick up truck, JUST as they were closing with me, near as I can tell the car "brake checked" the tailgating pick up. There was a shit ton of smoke, squealing tires and slewing vehicles coming right at me. Let me tell you I was on the brakes and checking my ditch for an escape path. Fortunately they mostly stayed on their side of the road. I think the truck did hit the car. Man there are idiots everywhere. Reviewing the situation, what I did, what else I might have done, I was damned glad I didn't have a cage on MY rear bumper. I'm pretty big on not letting that happen, but was basically too busy to check my mirrors.... I was also glad I had done a couple of hard stops earlier in the ride, First time out on this bike this season! When I first got this bike I heavily modified the front brakes so full stopping authority at reasonable lever pressure was available, the stock brakes were REALLY pathetic. Different calipers, SS lines, smaller MC, front tire that better matched the rim width than the stock balloon. Note; on this 850 pound low slung bike the rear brake does contribute quite a bit to stopping.

I just checked the brake rods on my later machines and they are M6 x 1.0, so that Virago wing nut should fit. The early brake rods must be different? According to parts diagrams, the '70-'73 brake rods and their corresponding adjuster nut do differ from the later ones. The brake rod I understand, because the early frames differed. You've discovered why the adjuster nut differs, it has a different thread size. So, it seems another obscure factoid has come to light, lol.

Is there enough meat to drill and tap for M8-1.00Unfortunately, the chrome winged Virago adjuster nut has the wrong thread size.

when checking rear wheel rotation with initial brake pedal application.

Just checked my 79F on the centerstand which infact does have the brake cam dimple positioned to the rear of the bike.

In my case with slight pedal application the rear wheel does noticably rotate in the clock wise direction or forward viewed from the brake side.

I do not know which brake shoe was top or bottom upon disassembly however and need to "break them in" with a ride.

Attachments

Well, that would seem to indicate your top or "leading" shoe is contacting the drum 1st. That would make sense with the cam installed wrong, that's what making it non-symmetrical is supposed to fix. I would give it a quick road test as is to see how well the brake works now, then "fix" it and road test again. Back to back tests, so to speak. Fixing it now and riding it 6 months later, you may not notice much.

Similar threads

- Replies

- 9

- Views

- 917

- Replies

- 13

- Views

- 441