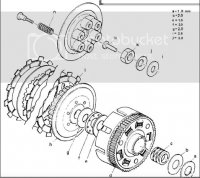

I am in the process of repairing the 4th gear friction clip to improve my new starter function. Indeed, I have completed that part of the job successfully thanks to the comprehensive write ups regarding the topic, on this Forum. Whilst replacing my clutch basket, I noticed a section of friction material broken away from one of the plates. Assuming this would not assist in the operation of a smooth clutch, I ordered 7 new plates and cleaned up the steel plates with 120 grit to leave a roughened surface. The starter now hums like a bee but, I have noticed a little movement in the clutch basket now that I have it all installed and ready to accept the new plates. I'm not talking a lot of wobble - maybe .5mm. I disassembled and rebuilt using this excellent diagram provided in a thread by 650 Bobber Boy. All washers are correct and in place - I doubled checked their placement and seating and measured their thickness against that offered in the diagram. The thrust bearing appears to be in good condition. I have applied 56.5 ft/lbs of torque to the hub nut. Everything appears to be done by the "book". There is a little movement in the shaft the basket sits on that could be reflected in the "wobble" I'm seeing in the completed assembly. Am I being pedantic? The motor is 42 years old and carries 22,000 miles however, I thought these "geared" fittings would seam together a little more solidly. Opinions?

Attachments

Last edited: