poorman9

XS650 Addict

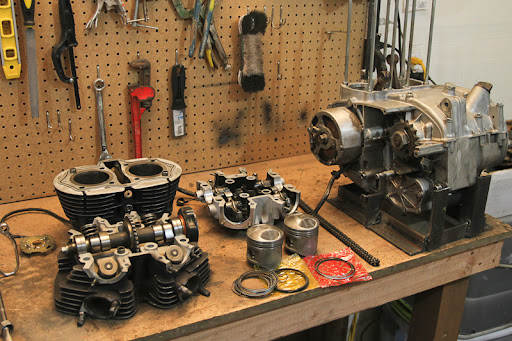

Here's the story - I bought this '81 XS650H as a pile of parts, it's got 9k on it, and was dissembled and left in a guys garage for several months. He took apart the top end because it was leaking oil, beyond that I know nothing about how the motor ran.

I've since:

Normally I'd just jump in, but this is something that I'd only like to do once. So I've got some questions --

1. What kind, if any, sealant should I use and what gaskets should I put it on?

2. When I had the pistons removed, I marked them 1 and 2, but I wiped off the marks on the cylinders so I have no idea which piston went in which cylinders. What should I do? 50-50 shot right

so I have no idea which piston went in which cylinders. What should I do? 50-50 shot right  ?

?

3. Copper washers - gasket set didn't come with any new ones, I know these are important, I've got three old ones sitting on my parts table, should I have more?

4. Should I grease my Camshaft Bearing? I've got Moly grease that I used on my steering bearings.

5. My gasket set came with valve stem seals, should I replace the old ones now? I don't know if this needs to be done, or how much of a pain it is.

6. My crankwheels have developed some light surface rust, check out the picture below, should I do anything about it?

Also, any tips similar to: "Don't forget to stagger the ring gaps," or anything else you've once messed up would be great!

I've since:

- Bought the Clymer manual

- Ordered a full set of gaskets from Mike's

- Got a new set of rings (read about that here)

- Had my cylinders miced and honed by a professional

- Replaced the master link in the cam chain

- Removed the sump filter

- Washed out the bottom-end with kerosene

- Bead blasted my cylinders, head and head cover

- Carefully cleaned dust and glass from blasting

- Removed any old bits of gasket from mating surfaces

- Cleaned and de-greased everything I could find

What's missing from this list?

Normally I'd just jump in, but this is something that I'd only like to do once. So I've got some questions --

1. What kind, if any, sealant should I use and what gaskets should I put it on?

2. When I had the pistons removed, I marked them 1 and 2, but I wiped off the marks on the cylinders

so I have no idea which piston went in which cylinders. What should I do? 50-50 shot right

so I have no idea which piston went in which cylinders. What should I do? 50-50 shot right 3. Copper washers - gasket set didn't come with any new ones, I know these are important, I've got three old ones sitting on my parts table, should I have more?

4. Should I grease my Camshaft Bearing? I've got Moly grease that I used on my steering bearings.

5. My gasket set came with valve stem seals, should I replace the old ones now? I don't know if this needs to be done, or how much of a pain it is.

6. My crankwheels have developed some light surface rust, check out the picture below, should I do anything about it?

Also, any tips similar to: "Don't forget to stagger the ring gaps," or anything else you've once messed up would be great!