sseres

XS650 Junkie

excited to have gotten my clutch upgrade cable in the mail this week. I had some time today but won't be able to finish the whole thing.

First thing I did was assemble my tools and get the bike up on my lift.

I don't know how you work on motorcycles without wifi and xs650.com up on the computer!

just a view of the original cabling how it inserts into the transmission.

the handlebar before I tear into it. It was at this time I realized the mirror is attached to the dang clutch level. I guess I'll have to figure out that one later.

First few steps involve taking off the shifter and left peg. Not too big of a deal. All of the screws that hold it in are the same size except for the very front one, and the frontmost on the bottom which are a bit longer . I was happy not to see the "oil death" that Hugh warned might be under there.

I really was surprised to find what looks like corrosion on the generator. Not sure if it's a new or old problem actually. I've not been having electrical charge issues with the bike, although I do ride a lot, and when I'm not it's on a battery tender. I think this will be something I tackle when I do the 277 rephase next winter.

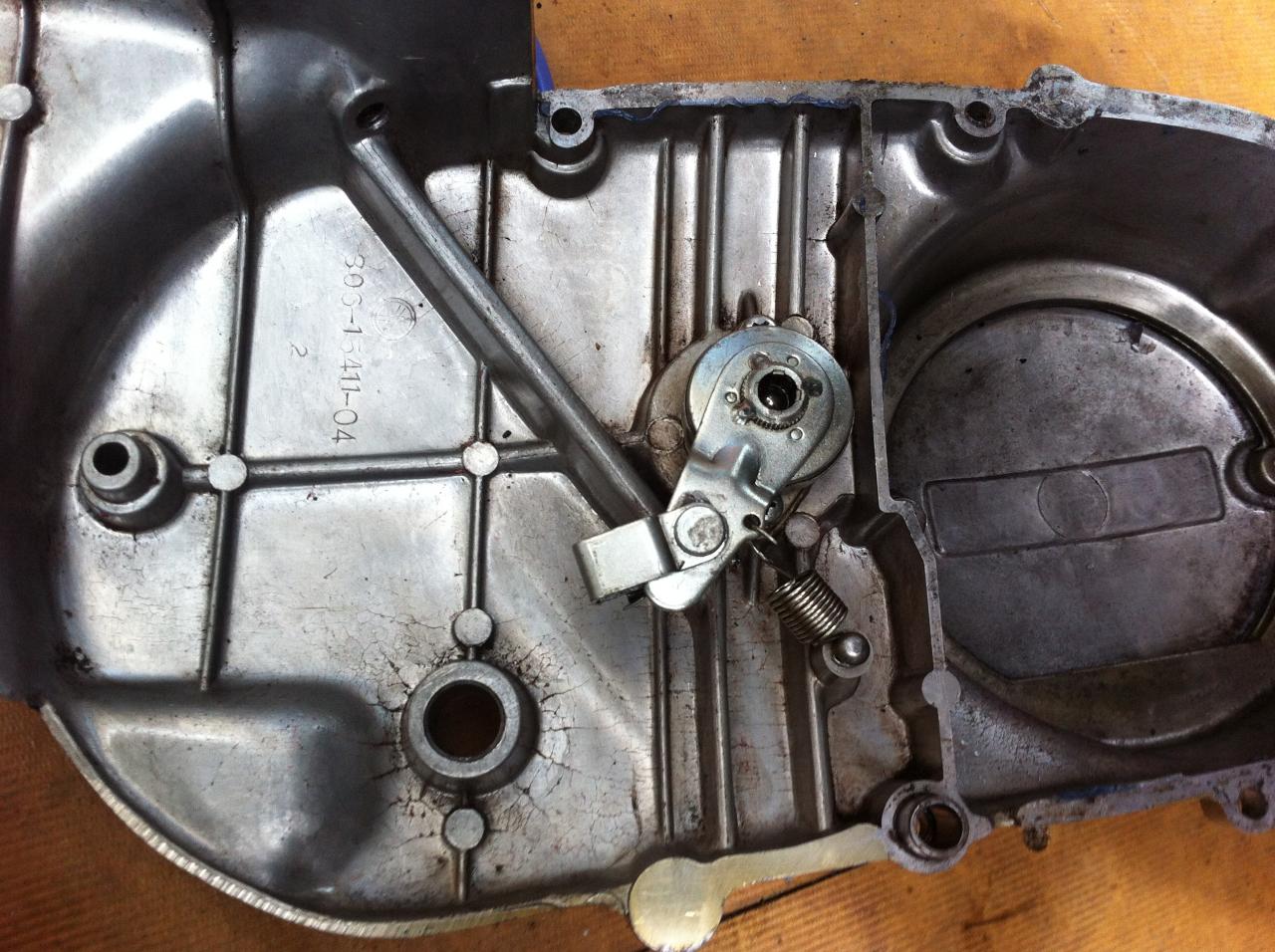

Close up of the clutch actuator. A bit of a grimey mess. I was reading up on best cleaning practices and it seems WD40 will be my friend here.

This was another weird surprise. Appears this harness had been touching the chain! Check out how it didn't get the inner wires, just the outter casing. I'll try to tie this up more securely with some zip ties before I put everything back together.

This was an "oh-dammit." I accidentally broke the original clutch lever/mirror mount taking it off.

This is the "rat's nest" in the headlight. It was really easy to trace the clutch switch in there and disconnect it.

Getting the grip off, I ran into whatever the frack this is.

Since I had the turn signal switch open, I shot it with some wd40 to get the cancel function to loosen up a bit.

My daughter couldn't pass up an opportunity to lend a hand.

Everybody needs to have a coworker like mine who has stuff like this to borrow.

I did have to invent a more clever way to get the bit in the cover. a socket set driver did a good job.

I mean, how cool is it you can put threads in something?

So, that's day one . Friends coming over soon and I need to help. I'm also out of WD40 so looks like I have to stop. This been a very cool project and Hugh's instructions are really spot on.

Again, keep me posted, shoot me an email if needed, but I wanna see you riding

Again, keep me posted, shoot me an email if needed, but I wanna see you riding

So we took 3 days away from the shop, and I am now stuck answering over 200 emails today

So we took 3 days away from the shop, and I am now stuck answering over 200 emails today  All part of the job, to make sure you folks stay happy - I'm not complaining - I love my job

All part of the job, to make sure you folks stay happy - I'm not complaining - I love my job  Heh heh, that's what she says!

Heh heh, that's what she says!