Was pretty pleased that the bike started easily even if the excessive revs had me leaping to turn the ignition off.

What I was less pleased about was the tacho needle leaping all over the place to the extent that I was sure it would be seriously damaged. After a lot of sucking of teeth I went to look on eBay only to find pretty poor stuff for sale, untested. The only decent one went for £130.

So I figured I'd pull it apart. What can I lose? Its broken already. At least I'll get to see the inside.

Pulled it apart and then found http://www.xs650.com/forum/showthread.php?t=31305 TwoManyXS1Bs step by step thread.

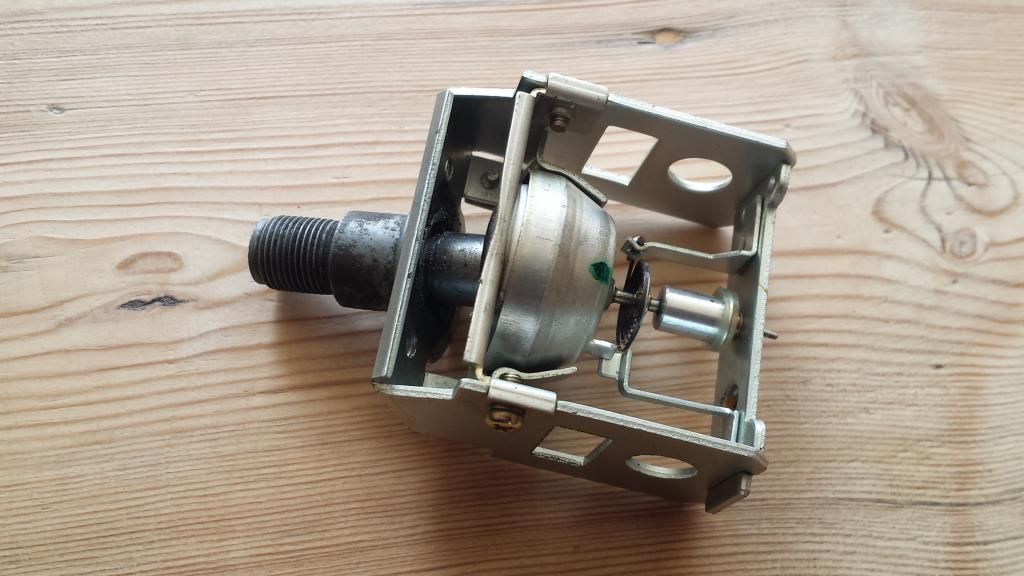

An iron magnetic disc rotates inside a metal cup. They don't touch but the faster the iron disc rotates the more it causes the cup to turn against the force of a hairspring. When the spinning stops the cup returns back to the zero position.

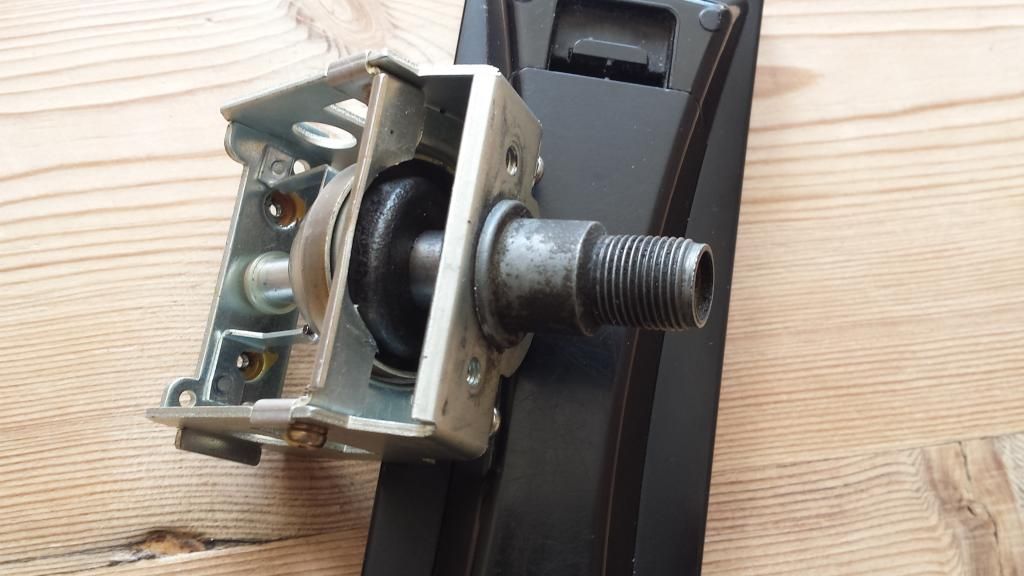

I couldn't see anything wrong but when I wiggled the threaded neck it wobbled and fell out. I guess it was supposed to be an interference fit. It wouldn't fit back in so I filed down the bent over edges until it fitted back in flush. I used a set of "diamond" files from a "we sell everything sort of shop" (£4)

Put a bit of grease on first where I was about to file so that filings wouldn't fly over onto the magnet and wiped off with paper tissues as I went. Used cotton buds and a dremel to clean all the grease and muck off I could get to and reassembled by putting a fillet of superglue around the cleaned edge figuring I could dremel it off again.

(It was a lot cleaner than the photos shown here.)

Re-assembled and it, so far, seems to work. Not sure if there was muck in between the cup and the disk or the disk was not being held centrally but hey, its fixed, I hope.

The guage was pretty easy to pry open provided you're patient and at least on mine (XS650B) any damage is hidden by a large rubber ring.

Hope this helps someone else.

Dave

What I was less pleased about was the tacho needle leaping all over the place to the extent that I was sure it would be seriously damaged. After a lot of sucking of teeth I went to look on eBay only to find pretty poor stuff for sale, untested. The only decent one went for £130.

So I figured I'd pull it apart. What can I lose? Its broken already. At least I'll get to see the inside.

Pulled it apart and then found http://www.xs650.com/forum/showthread.php?t=31305 TwoManyXS1Bs step by step thread.

An iron magnetic disc rotates inside a metal cup. They don't touch but the faster the iron disc rotates the more it causes the cup to turn against the force of a hairspring. When the spinning stops the cup returns back to the zero position.

I couldn't see anything wrong but when I wiggled the threaded neck it wobbled and fell out. I guess it was supposed to be an interference fit. It wouldn't fit back in so I filed down the bent over edges until it fitted back in flush. I used a set of "diamond" files from a "we sell everything sort of shop" (£4)

Put a bit of grease on first where I was about to file so that filings wouldn't fly over onto the magnet and wiped off with paper tissues as I went. Used cotton buds and a dremel to clean all the grease and muck off I could get to and reassembled by putting a fillet of superglue around the cleaned edge figuring I could dremel it off again.

(It was a lot cleaner than the photos shown here.)

Re-assembled and it, so far, seems to work. Not sure if there was muck in between the cup and the disk or the disk was not being held centrally but hey, its fixed, I hope.

The guage was pretty easy to pry open provided you're patient and at least on mine (XS650B) any damage is hidden by a large rubber ring.

Hope this helps someone else.

Dave