This morning, I put the saddle on the knee and bolted on the guide plates.

After inserting the gibs, I found my next challenge. The gibs stick so far out the back of the saddle that the rear gib adjusters don't engage the threaded hole. There are two adjusters per gib in a push-me/pull-you arrangement, when they are both tightened the gib adjustment is locked in place.

Both adjusters are supposed to be nearly flush like the second picture if the gib is the correct thickness and length. In order to get them into that range, I calculated that a shim of between 0.009" and 0.011" (depending on which of the three gibs) is required to get them into the correct position. I have 0.010" shim stock on order for pick-up tomorrow morning from my favorite hardware store.

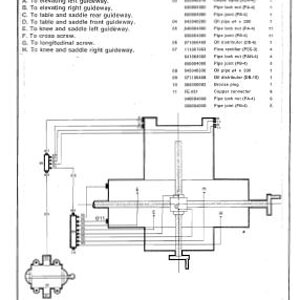

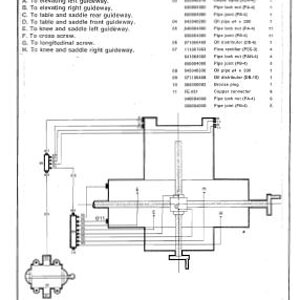

The other thing I found is that half of the lube points for the one-shot lube system are on top of the saddle and UNDER the table. I was planning on putting the saddle on, followed by the table and THEN figuring out the lube lines but that won't work so I started looking into the lube system. Here's what I have to start with. The lube system came in a five-gallon bucket and appears to be all there. I say appears as I found another diagram in a different version of the manual and neither one matches exactly what I have but they are both close.

Since I was ordering shim stock from McMaster, I added a roll of 4mm nylon tubing and some compression sleeves in the hopes that I can use the pump (assuming it still works), the distribution blocks, meters and fittings and only have to replace the aluminum tubing with the nylon. Fingers crossed. At least I've ID'd all the lube points so that's something. Only one is left in question, one diagram shows two points on one end of the saddle and the other shows one on each end. My saddle has all three, so I'll have to figure out which ones I really need by checking all the drillings and see how they are interconnected.

After inserting the gibs, I found my next challenge. The gibs stick so far out the back of the saddle that the rear gib adjusters don't engage the threaded hole. There are two adjusters per gib in a push-me/pull-you arrangement, when they are both tightened the gib adjustment is locked in place.

Both adjusters are supposed to be nearly flush like the second picture if the gib is the correct thickness and length. In order to get them into that range, I calculated that a shim of between 0.009" and 0.011" (depending on which of the three gibs) is required to get them into the correct position. I have 0.010" shim stock on order for pick-up tomorrow morning from my favorite hardware store.

The other thing I found is that half of the lube points for the one-shot lube system are on top of the saddle and UNDER the table. I was planning on putting the saddle on, followed by the table and THEN figuring out the lube lines but that won't work so I started looking into the lube system. Here's what I have to start with. The lube system came in a five-gallon bucket and appears to be all there. I say appears as I found another diagram in a different version of the manual and neither one matches exactly what I have but they are both close.

Since I was ordering shim stock from McMaster, I added a roll of 4mm nylon tubing and some compression sleeves in the hopes that I can use the pump (assuming it still works), the distribution blocks, meters and fittings and only have to replace the aluminum tubing with the nylon. Fingers crossed. At least I've ID'd all the lube points so that's something. Only one is left in question, one diagram shows two points on one end of the saddle and the other shows one on each end. My saddle has all three, so I'll have to figure out which ones I really need by checking all the drillings and see how they are interconnected.