Noidea

XS650 Addict

Hey all been a while since i posted on here but ive been around reading old threads finding answers through other people problems for the most part. Now I got my own set of questions that I haven’t found in other threads. (Please link me to others if I overlooked them)

Ive got a 73 motor Hughes CDI kit with Vm34s at “baseline”spec

180 Main

22.5pilot

22mm float height

Middle slot on needle

Air jet removed

Unibpod filters

Pandonium ya mama exhaust

Main question I have is should my top throttle adjustment be screwed out this much to maintain idle at 1200?

I see in the carb guide theres a section on cable adjustment Stating

“Bear in mind that the carb-top cable adjustors are used to set lift synch; if they must be turned out to eliminate cable slack, the cable assembly is too long.”

It won’t really idle without throttle unless i have it at this setting. On the cable itself the adjuster is also maxxed out. Can someone send the thread the grizld speaks about in the guide using a cable adjuster to take up slack?

My throttle stop screws obviously don’t do much in this situation since the slide is set higher than the stop screw can go which makes me wonder if I’m cheating my idle. Ive read and continue to reread the carb guides both bs version and vm as well as the sudco guides. Didnt see much there fir it besides that those screws are for throttle sync. It does run ok i still need to tune it properly justworkin on a proper idle as i should.

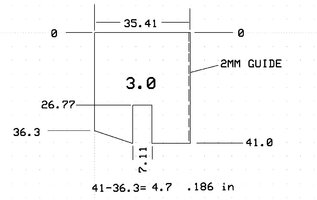

Alsooooo anybody have any ideas of way to use this empty space seeing as I’m not running points or a mechanical advance anymore?

Ive got a 73 motor Hughes CDI kit with Vm34s at “baseline”spec

180 Main

22.5pilot

22mm float height

Middle slot on needle

Air jet removed

Unibpod filters

Pandonium ya mama exhaust

Main question I have is should my top throttle adjustment be screwed out this much to maintain idle at 1200?

I see in the carb guide theres a section on cable adjustment Stating

“Bear in mind that the carb-top cable adjustors are used to set lift synch; if they must be turned out to eliminate cable slack, the cable assembly is too long.”

It won’t really idle without throttle unless i have it at this setting. On the cable itself the adjuster is also maxxed out. Can someone send the thread the grizld speaks about in the guide using a cable adjuster to take up slack?

My throttle stop screws obviously don’t do much in this situation since the slide is set higher than the stop screw can go which makes me wonder if I’m cheating my idle. Ive read and continue to reread the carb guides both bs version and vm as well as the sudco guides. Didnt see much there fir it besides that those screws are for throttle sync. It does run ok i still need to tune it properly justworkin on a proper idle as i should.

Alsooooo anybody have any ideas of way to use this empty space seeing as I’m not running points or a mechanical advance anymore?