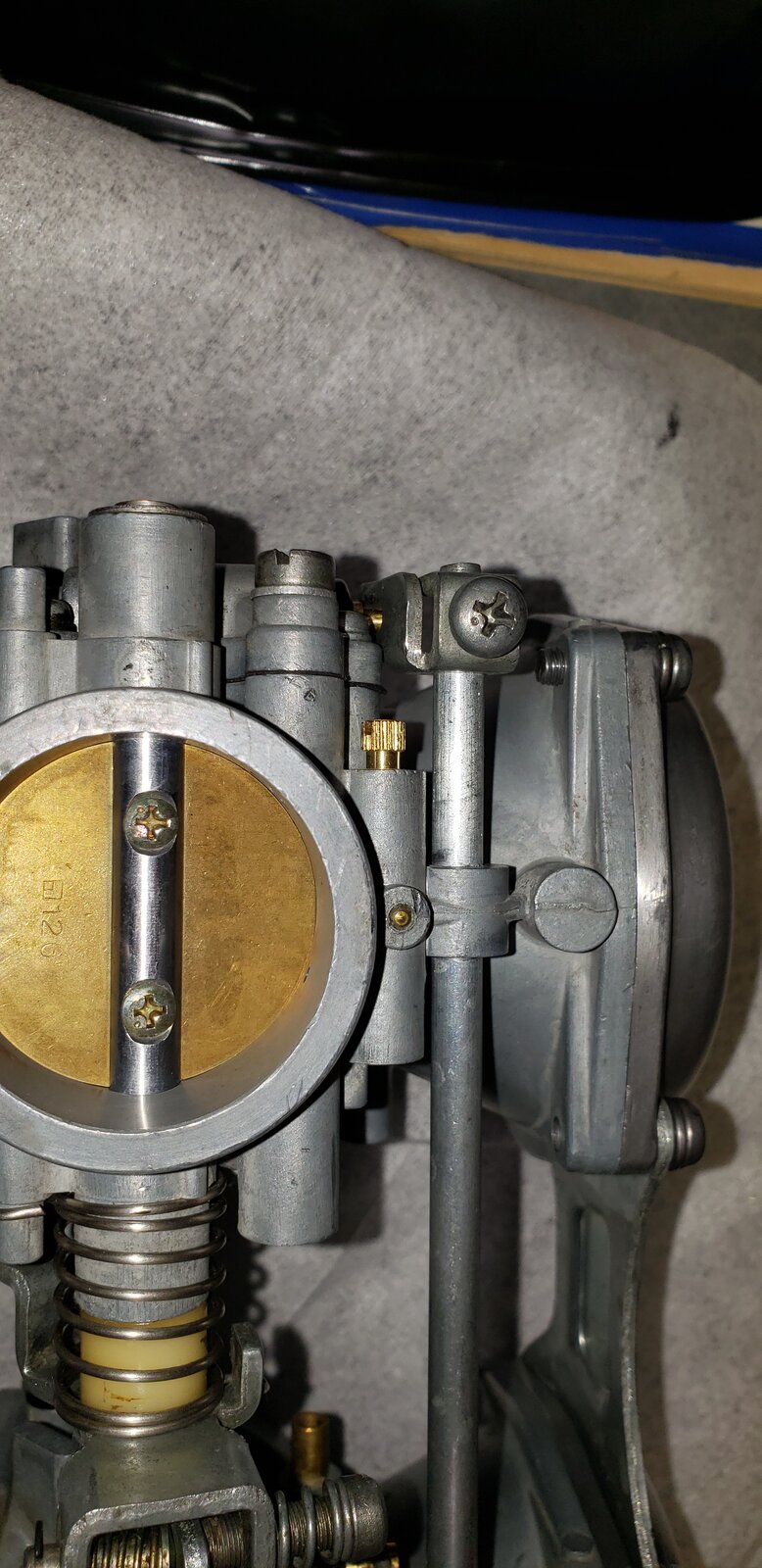

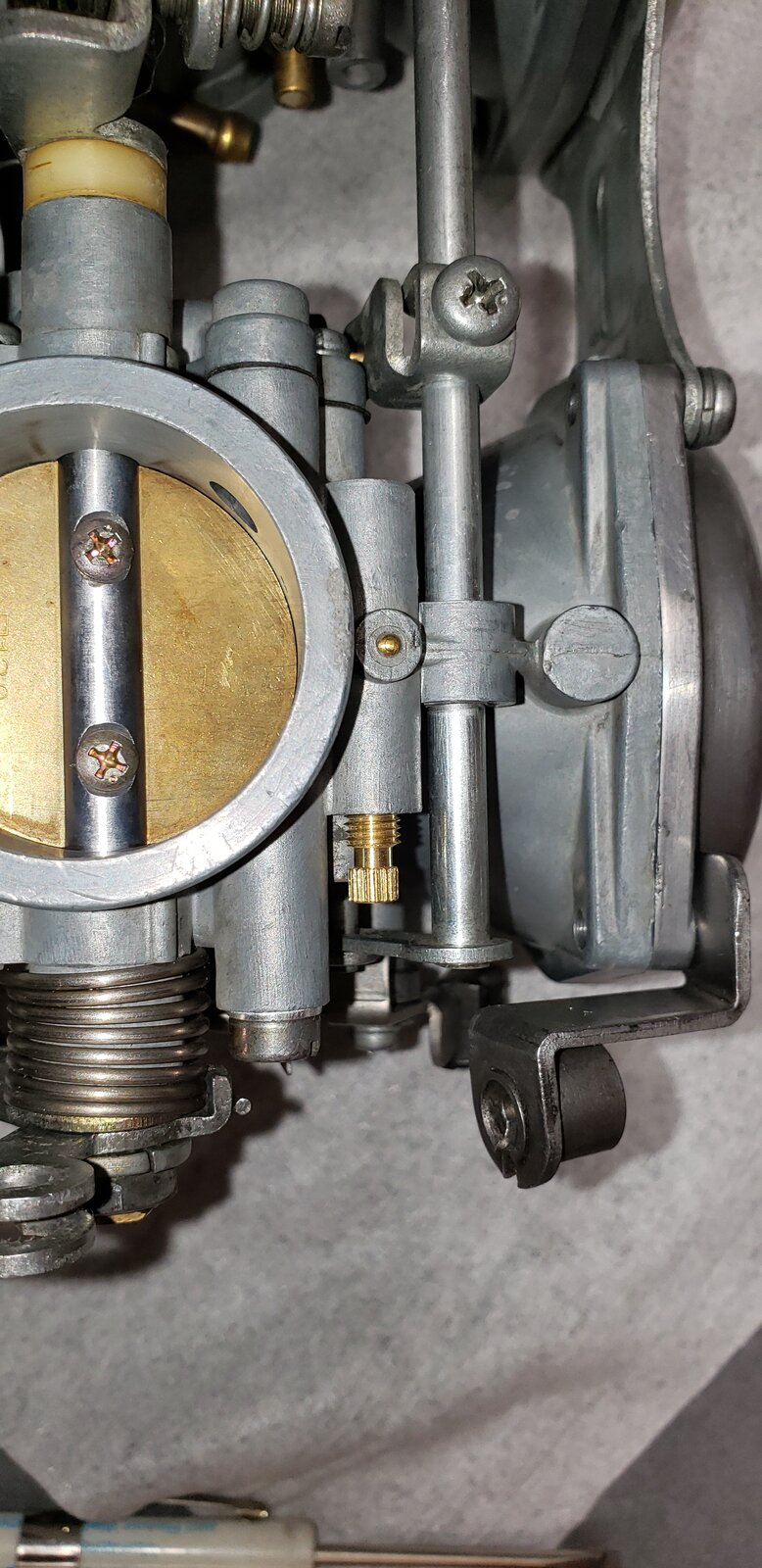

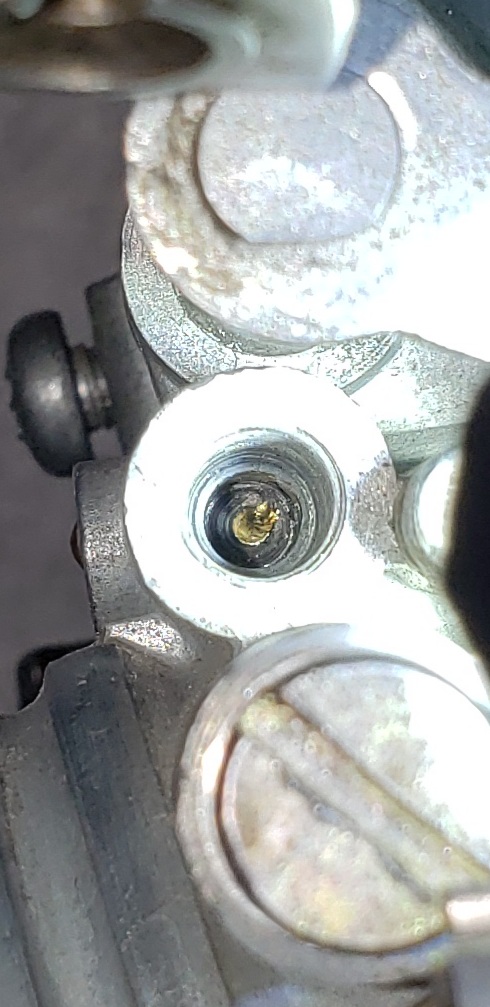

5T, yes, further detective work has found that either screw turns in properly just like your photo, into the right carb only. Attached are photos of right and left carb with screws installed, backed out 1.5 turns. The depth of the hole is identical at 19 mm but the left carb seat is compromised and the tip of the needle is not going down deep enough into the wee centre hole as it appears the seat is mashed. Photos of right and left seat also attached. Perhaps that bent tip screw damaged this seat when used by the PO?

Sucks because these carbs are otherwise in much better condition than the original '74 carbs. Any more ideas? Perhaps just use one of the other screws to turn down through this mess, or perhaps install the carbs and see how it goes?

Sucks because these carbs are otherwise in much better condition than the original '74 carbs. Any more ideas? Perhaps just use one of the other screws to turn down through this mess, or perhaps install the carbs and see how it goes?