So the 'easy' refurbishment isn't so easy after all. My recently acquired machine (following a 23 year chase; see previous posts) needs more attention than originally thought. After many years of being a 'display' item in a man-cave all seals were shot; carbs are gunked, and electrical sparks are iffy!

A thorough service and look over has become a full refurbishment. So the build begins.

Already stripped down to a rolling chassis; I have replaced all the original left hand seals one of which was leaking (main crank). Engine oil replaced with classic 20/50 which is my preferred oil for older motors.

Image below is before seal were changed.

Cleaned up all the electrical parts on this side, also and fitted new brushes to specification.

I am having trouble tightening (to torque) the securing bolt on the end of the rotor however. Its well seated on the shaft with the wood-ruff key in the correct position. Any tips on that one would be welcome? Motor runs OK but a bit fluffy on idle.

So to check the static timing. Crank marks are in place as required. I removed the points covers expecting to see 'points' or and electric ignition system on the end of the cam shaft but..... Nothing!

Whats going on?! Sparks is not my strong suit to be honest so any help with this would be grateful.

Below are the rest of the electrics on the bike:

The bike seems to run OK when revved; but when idling is a bit lumpy.

I think the carbs need a full going over and setting up carefully.

Wheel bearings and all service areas have been lubricated, including cables.

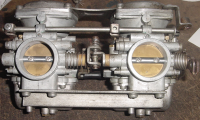

Finally the carburetors are off for a thorough clean and rebuild. Cleaning is going well, but I cannot identify which carb type I have to order the rebuild kits. There are no model marks on the bodies. Any spotters to help please?

I know there are a few questions contained here; but all help is willingly and gratefully received.

I will keep this post going as the build develops.

Cheers

Adam

A thorough service and look over has become a full refurbishment. So the build begins.

Already stripped down to a rolling chassis; I have replaced all the original left hand seals one of which was leaking (main crank). Engine oil replaced with classic 20/50 which is my preferred oil for older motors.

Image below is before seal were changed.

Cleaned up all the electrical parts on this side, also and fitted new brushes to specification.

I am having trouble tightening (to torque) the securing bolt on the end of the rotor however. Its well seated on the shaft with the wood-ruff key in the correct position. Any tips on that one would be welcome? Motor runs OK but a bit fluffy on idle.

So to check the static timing. Crank marks are in place as required. I removed the points covers expecting to see 'points' or and electric ignition system on the end of the cam shaft but..... Nothing!

Whats going on?! Sparks is not my strong suit to be honest so any help with this would be grateful.

Below are the rest of the electrics on the bike:

The bike seems to run OK when revved; but when idling is a bit lumpy.

I think the carbs need a full going over and setting up carefully.

Wheel bearings and all service areas have been lubricated, including cables.

Finally the carburetors are off for a thorough clean and rebuild. Cleaning is going well, but I cannot identify which carb type I have to order the rebuild kits. There are no model marks on the bodies. Any spotters to help please?

I know there are a few questions contained here; but all help is willingly and gratefully received.

I will keep this post going as the build develops.

Cheers

Adam

Last edited: