I’m hoping someone can offer some help in clearing the hurdle I’ve stumbled at today.

When trying to disassemble my YZF R6 calipers I’ve come across a problem I thought I’d enquire about before I mess something up.

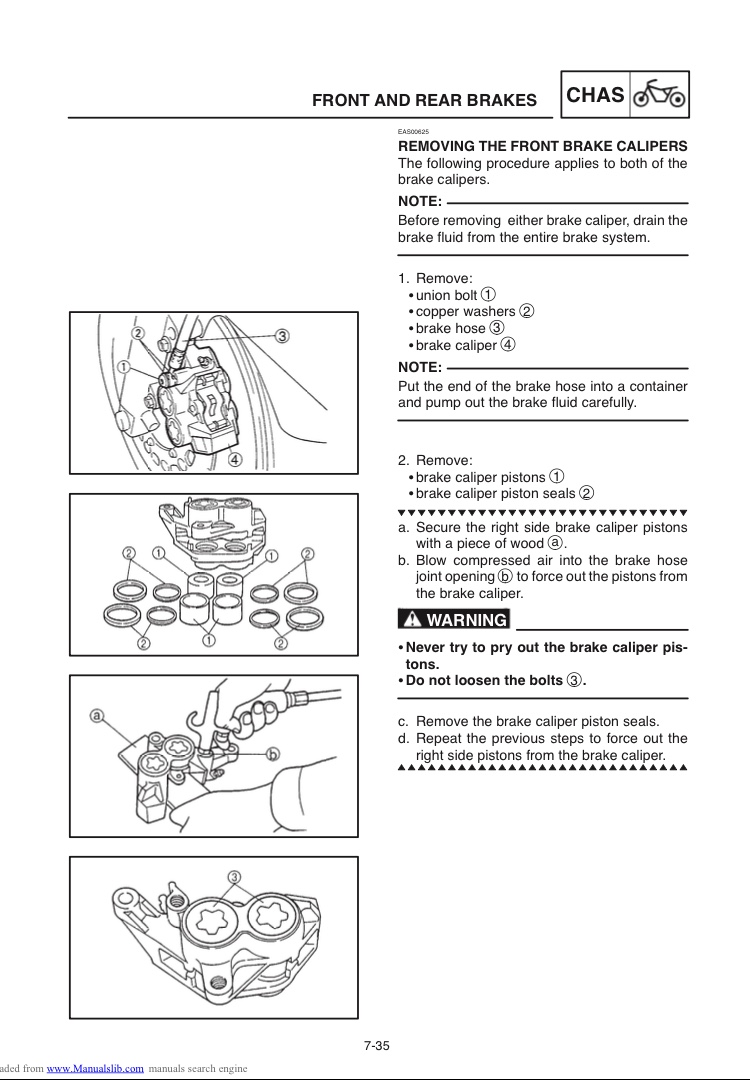

So obviously I’ve followed the guidance in the service manual.

My first problem is that not all of the pistons were forced out by the air blasted into the caliper, meaning that it’s difficult to create a decent seal to pop the remaining pistons out.

I hope this post makes sense? If anybody can offer any guidance I’d be hugely appreciative as I’m a little stuck at the moment.

Daniel.

When trying to disassemble my YZF R6 calipers I’ve come across a problem I thought I’d enquire about before I mess something up.

So obviously I’ve followed the guidance in the service manual.

My first problem is that not all of the pistons were forced out by the air blasted into the caliper, meaning that it’s difficult to create a decent seal to pop the remaining pistons out.

I hope this post makes sense? If anybody can offer any guidance I’d be hugely appreciative as I’m a little stuck at the moment.

Daniel.

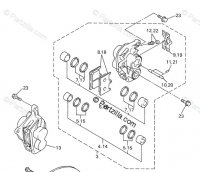

Attachments

Last edited: