Squishman

XS650 Addict

Thanks rsor. I was trying to find it in the PDF manual link that Yamadude posted. Also couldn't find the size online.

I may have those. I'll check.Yes, it's 36mm. Another size you may want to get is 27mm, for the oil drain plugs and rear axle. Front axle is a 22mm.

Keep in mind that there is some "overlap" between SAE and metric sizes.I may have those. I'll check.

Thx. I have the 36 on order from Amazon. And I have the other two already. 27 is a deep socket.Keep in mind that there is some "overlap" between SAE and metric sizes.

Off the top of my head, I think I use my 1 7/16 socket in place of the 36mm, and the 1 1/16 for the 27mm

Those larger metric sockets can be pricey. I got my SAE 3/4 drive jumbo socket set from Harbor freight years ago for pocket change.

Its $75 now.

View attachment 264269

.

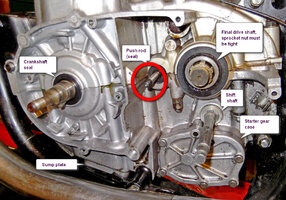

Do you think it's possible that your gasget maker application could solve it if its just a minor leak at the primary drive seal?The early models actually spec it a little tighter, 94 ft/lbs. That's what I use and it seals well. I started out using about 72 ft/lbs I think. I didn't get drips but there were always oil streaks on the sprocket emanating from the shaft. Upping the torque to 94 eliminated them ......

View attachment 264224

Since the leaks in that area are from oil running out between the shaft and the sleeve spacer, I now take some additional steps to seal it. I put gasket sealer on the back of the sprocket where it contacts the sleeve, and also on the back of the lock washer and the nut .....

View attachment 264225

View attachment 264226

Was your sprocket loose? If not that seal is fairly easy to replace if needed.Do you think it's possible that your gasget maker application could solve it if its just a minor leak at the primary drive seal?

As I mentioned before, you said there's less than 2k on the motor since the PO went through it. Do you have any reason to suspect he put the motor back together with old wore out seals?Do you recommend putting in a seal anyway?

No reason at all.As I mentioned before, you said there's less than 2k on the motor since the PO went through it. Do you have any reason to suspect he put the motor back together with old wore out seals?

Like I mentioned, it wasn't loose, just seemed not torqued. I wonder if that was enough "loose" to cause a leak. It could very well be he did torque it, then for whatever reason it became that way. Yes, the washer was folded.Getting the lock tab and nut aligned correctly before tightening is futsy it's easy for that slotted washer to get out of place creating a "false" tight. Don't be afraid to get it tight and be SURE to fold down a lock tab or that sprocket will come loose. And most of the time that what the leak is a loose sprocket, not a bad seal.

View attachment 264355

I've always thought of these leaks as "self-oiling chain" lol.

When I ordered the kit, I asked him if he could add another push rod seal and then send me an invoice for the extra part. He said "I'll take care of it". I said, terrific, thanks! Well, he sent me a whole extra pack, so I have 2 of each! What a guy!When you order a new one, buy two. It’s not uncommon to booger one up upon the install. Plus always good to have an extra on hand.

Happy daysWhen I ordered the kit, I asked him if he could add another push rod seal and then send me an invoice for the extra part. He said "I'll take care of it". I said, terrific, thanks! Well, he sent me a whole extra pack, so I have 2 of each! What a guy!

Good info 5twins! The push rod seal looked dry, except for the grime under the cover. The back of the sprocket had a small amount of clean oil on it. So, that is encouraging that it might just need re-torquing. Btw, the bike had 7k on it when the previous owner built it up, under 1300 miles since then. So it is a relatively low mileage machine.Your sprocket nut was too loose if you could get it off with just channel locks. You'll notice as you torque it that the nut doesn't move much to go from, say, 50 up to 80 or 90 lbs. That means it doesn't have to move much to loosen up. Even with the lock washer folded up against the nut, it can still come loose. I wouldn't change the seal now, I'd just properly torque the nut first. That'll likely cure your leak.

If you do the clutch pushrod seal, check the bushing under it that supports the rod too. They are often worn and even a new seal may not work if the bushing is worn too much. The original was 8mm long. MikesXS sells a 10mm long replacement which is better, but you can use a 12mm long one, and that's even better still. You can also get them much cheaper from McMaster-Carr. As you can see, my original was worn noticeably thinner compared to the new ones .....

View attachment 264505

View attachment 264506

View attachment 264507