Time for a bit of an update.

I have been doing stuff but made an adjustment to my phone and could not send photos from it to my email. All fixed now but took a while to find out what I had done.

After the disaster of Boxing day the bike was repaired, new pistons and the pipe repaired turns out the wrong pistons were installed in the bike at its last motor strip, the pistons used were out of hours and you can see what happened.

Since the meeting at Pukekohe was the last classic meeting (the track is being closed) my mate thought he would run the bike without mufflers thinking that if they ban him so what.

Two surprises the bike was not that loud and had noticeably more horsepower. The lack of noise was not a huge surprise as the end of the stingers were placed inside the baffle cone for that very reason, but the extra power was. At present we are running without mufflers until told to do so.

We obviously got the muffler design wrong. The bike is running well and has been reliable. Some things we are looking at doing when the crank is rebuilt next is to make it a cross plane as loss of rear wheel traction is a problem when the bike comes on the pipe. Hopefully going away from the big bang motor will improve traction.

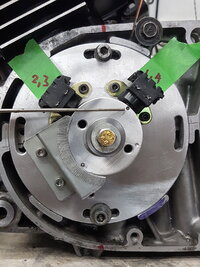

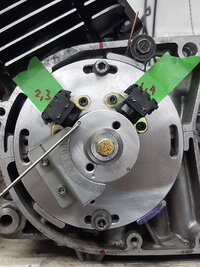

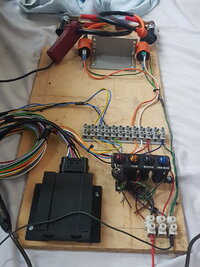

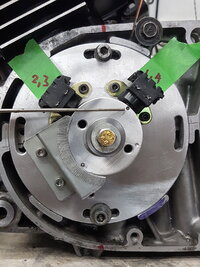

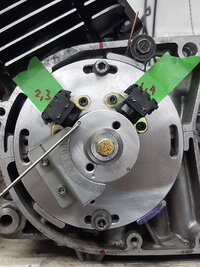

The crank is no problem but a new ignition will be required, I have been making a new rotor with two magnets and a backing plate to hold two pick up coils. They will feed into an Ignitech ignition so we will need to run a battery. The battery can also power the rain light and the gear position indicator which at the moment runs off a small 9V dry cell. The new ignition can still use the coils we have that are for CDI and can still be a wasted spark so we don’t need to mount new coils.

The rotor is keyed onto the tapered shaft, the 2 magnets 180 degrees apart are held in place by welding wire pins and the holes will be seal with epoxy, the 2 x 6mm holes are for mounting the rotor puller. The dot on the face is an error.

The pick ups are 90 degrees apart.

How the cross plane crank and ignition works.

Crank configuration:

Pistons 1 and 4 are 180 degrees offset, pistons 2 and 3 are 180 degrees off set.

Piston 1 is 0 degrees piston 2 is + 90 degrees piston 3 is +270 degrees piston 4 +180 degrees

For this explanation assume firing at TDC. This is a wasted spark ignition system.

Condition 1

Piston 1 is TDC , piston 2 is 90 degrees BBDC, piston 3 is 90 degrees BTDC, piston 4 is BDC.

Plugs 1 & 4 spark, cylinder 1 ignites, cylinder 4 has no compression and does not ignite.

Condition 2

Piston 1 is 90 degrees BBDC , piston 2 is BDC, piston 3 is TDC, piston 4 is 90 degrees BTDC

Plugs 2 & 3 spark, cylinder 3 ignites, cylinder 2 has no compression and does not ignite.

Condition 3

Piston 1 is BDC , piston 2 is 90 degrees BTDC, piston 3 is 90 degrees BBDC, piston 4 is TDC

Plugs 1 & 4 spark, cylinder 4 ignites, cylinder 1 has no compression and does not ignite.

Condition 4

Piston 1 is 90 degrees BTDC , piston 2 is TDC, piston 3 is BBDC, piston 4 is 90 degrees BBDC

Plugs 2 & 3 spark, cylinder 2 ignites, cylinder 3 has no compression and does not ignite.

I hope you find this of interest.

In addition to this I would like to fit larger reed blocks (I have them on the shelf) and bore the carbs they are rather asthmatic (28mm) before buying larger ones.

Of interest to other RD 350 owners is that US spec ported new cylinders are being made by China now. I have read they have also fixed the casting so that the liners do not slip out of the castings as well. There are old and new cylinders on the market at the moment, you can tell them apart apparently but I am awaiting photos. This is good news because fixing the Indian spec cylinders is a ton of work.

In other news

There are changes coming to the modern sidecar class as well the type of motors allowed is changing and they are proposing allowing two strokes up to 500cc. I went to see my mate a few weeks ago and he had these 250's on his bench….