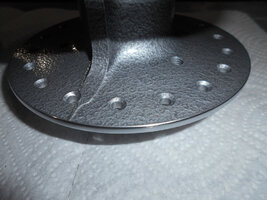

Today I polished the hubs and other bits and painted the centers my usual gray hammered finish. Perfect conditions for that.

New 19" rims, spokes, tires, tubes, and bearings & seals are here. After I get the wheels spoked and tires mounted and balanced I`ll measure and order the spun aluminum moon discs. The correct tires will let me finally figure out the ground clearance so I can lay out the frame (sorta).

I also finished stripping a lower case to use for mock up. Cylinder studs were a real SOB!

View attachment 256993View attachment 256994View attachment 256995View attachment 256996

Another thought is if I put the lower motor mount in the center of the bottom rail what might be on the motor that would extend below the rail with the motor installed?? Looks like tomorrow I need to make a lower case for mock up purposes.

Another thought is if I put the lower motor mount in the center of the bottom rail what might be on the motor that would extend below the rail with the motor installed?? Looks like tomorrow I need to make a lower case for mock up purposes.

Sorry I must have got that confused with the NHRA.

Sorry I must have got that confused with the NHRA.