Gunnar

XS650 Enthusiast

Thanks Vlad! Go Eastern Europe!

This is a very helpful diagram! Going to try to figure it out this weekend!

I also just got a torque wrench, I knew they were gentle. There was no resistance at all and the next thing I found head popped off. I was also, making sure I screw them equally as well.

Thanks 650Skull, I will definitely check if I have bent it. It's aluminum, so I assume it's easy to do.

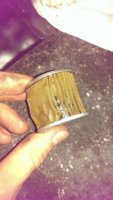

Here are pictures of oil filters that I took out. My mechanic friend says they scream trouble because these metal chunks came from a piston and I need to check the pressure in the chamber. is that true?

This is a very helpful diagram! Going to try to figure it out this weekend!

I also just got a torque wrench, I knew they were gentle. There was no resistance at all and the next thing I found head popped off. I was also, making sure I screw them equally as well.

Thanks 650Skull, I will definitely check if I have bent it. It's aluminum, so I assume it's easy to do.

Here are pictures of oil filters that I took out. My mechanic friend says they scream trouble because these metal chunks came from a piston and I need to check the pressure in the chamber. is that true?