Your cylinder barrels look very smart. Have you sprayed them with something? Mine are showing a little corrosion in places, especially behind the oil feed-line in front. They need to be treated with sometime.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stella - 1977D survivor, back on the road.

DanielBlack

XS650 Junkie

Thank you. I attribute Stella's fine complexion to her life in the dry climate in the American SW. As far as I know, she hasn't had a full restoration.

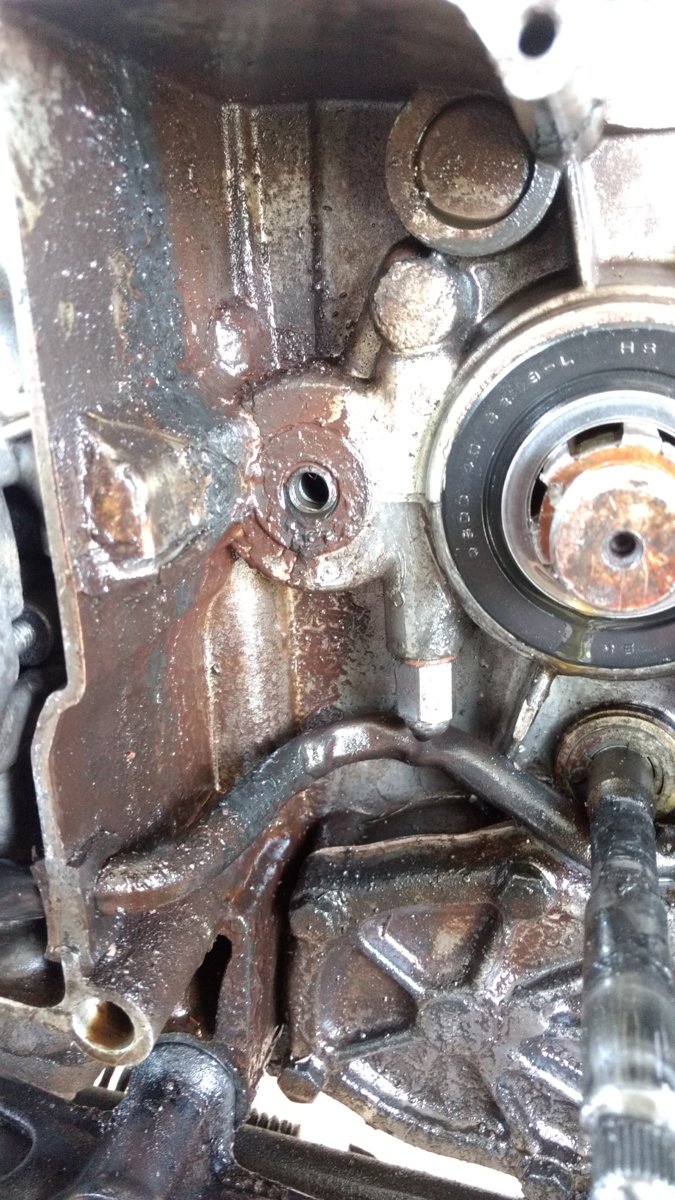

oooooohhh - yuk-ola DB. I hope you have several seals as just about everyone who has talked about this job says that they ruin more than one getting the danged thing installed.

Anyhow - delighted that Stella is running well and that you are getting to enjoy her!

Pete

Anyhow - delighted that Stella is running well and that you are getting to enjoy her!

Pete

DanielBlack

XS650 Junkie

I've got two!

Even though the clutch pushrod seal is the usual culprit here, the countershaft seal can leak like crazy too if that big nut holding the sprocket on has come loose. It needs to be really tight, like 90 ft/lbs, for that seal to work good. And even with that lock washer with the sides bent up, they still come loose.

Even though the clutch pushrod seal is the usual culprit here, the countershaft seal can leak like crazy too if that big nut holding the sprocket on has come loose. It needs to be really tight, like 90 ft/lbs, for that seal to work good. And even with that lock washer with the sides bent up, they still come loose.

Yup, I've heard that before and, while I can imagine it leaking badly, it is hard to fathom how the nut comes loose with the lock washer bent properly.

DanielBlack

XS650 Junkie

Indeed. Tightened to 90# back in October. Maybe 1250mi? Already loose.

The clutch pushrod seal might not be the only culprit, but it was most definitely part of the conspiracy.

The clutch pushrod seal might not be the only culprit, but it was most definitely part of the conspiracy.

You mean the output shaft nut is already loose after you tightened it?

Good grief!

Good grief!

DanielBlack

XS650 Junkie

Yes! I wouldn't say loose, but I barely touched it with the wrench. 90#, it was not!

wow - a bit scary....

DanielBlack

XS650 Junkie

When I did my clutch seal , I also checked my sprocket nut and I literally spun it off with my fingers. I've got a feeling it's something that's going to require ongoing checks. Good luck with your seal replacement Daniel.

DanielBlack

XS650 Junkie

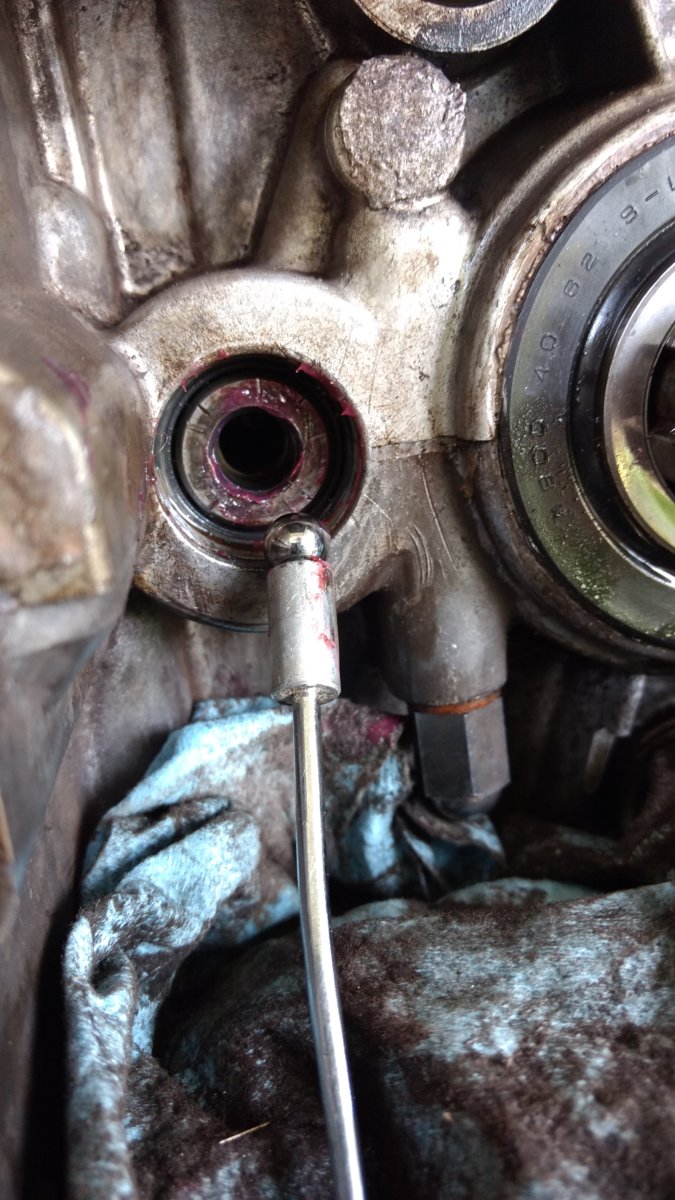

Complete! I had the first attempt halfway in and remembered the gasket maker. Damn. The second went in just as easy.

Thanks to the PO ahead if me, the sharp edge on the case had already been taken care of.

Packed with grease to catch debris.

The old bushing came out with the first bit.

Like a telescopic pick-it-up magnet tool, this one has a flexible stick.

New bushing and seal. Long pushrod replacing the two short rods and one ball bearing. There used to be a millimeter or so of side-to-side play. Now there is practically no play.

Thanks to the PO ahead if me, the sharp edge on the case had already been taken care of.

Packed with grease to catch debris.

The old bushing came out with the first bit.

Like a telescopic pick-it-up magnet tool, this one has a flexible stick.

New bushing and seal. Long pushrod replacing the two short rods and one ball bearing. There used to be a millimeter or so of side-to-side play. Now there is practically no play.

Very nice and tidy - great work DB!

Very nice work there Daniel, and great photos as well. When I went to drill out my bushing, the drill bit spun the bushing in the case but wouldn't bite into it at first. I was afraid of pushing it into the case. I'm glad yours came out easy.

That's a good job to have behind you.

That's a good job to have behind you.

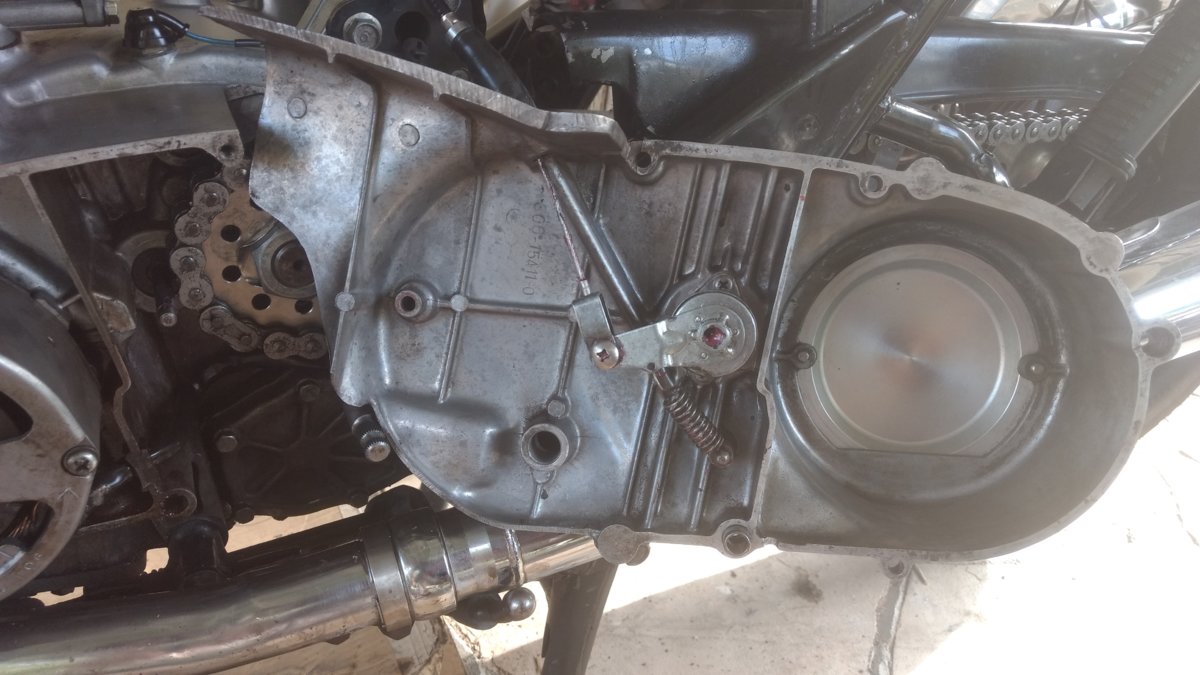

Yes, very nicely done. Yes, any sealer will probably work fine on the sprocket. Your last pic above nicely illustrates the problem. Many times the seal isn't the culprit here. Oil runs out along the splined shaft. To keep it in there, you need to seal the back of the sprocket against the bushing in the seal and the back of the nut and washer to the front of the sprocket. Making the nut really tight helps but so does a little gasket sealer on those contact areas.

DanielBlack

XS650 Junkie

Permatex Motoseal on the sprocket/bushing interface.

The sprocket/washer.

Washer/nut. It didn't look like that much as I was at it. Hmm.

Torqued to 80+#. My wrench goes up to 80, so I went until it clicked and just a bit more.

Clutch worm cleaned up, greased, reassembled.

She's all buttoned up, the bulk of the oil and grease cleaned off the bottom again. Ready for a spin.

The sprocket/washer.

Washer/nut. It didn't look like that much as I was at it. Hmm.

Torqued to 80+#. My wrench goes up to 80, so I went until it clicked and just a bit more.

Clutch worm cleaned up, greased, reassembled.

She's all buttoned up, the bulk of the oil and grease cleaned off the bottom again. Ready for a spin.

Daniel - you do really nice work!

I'm comin' down tomorrow so you can do mine while I sit on my duff and enjoy the warm Arizona sun! I'll bring along the BEvERages and the All-Dressed Chips (I don't think you have that delicacy in the US).

Cheers,

Pete

I'm comin' down tomorrow so you can do mine while I sit on my duff and enjoy the warm Arizona sun! I'll bring along the BEvERages and the All-Dressed Chips (I don't think you have that delicacy in the US).

Cheers,

Pete

Daniel, thanks for that little photo essay. I wasn't really clear how the whole gasket sealer thing worked with the sprocket and sprocket nut. That really cleared it up for me. I also still have a little dripping action on my output shaft seal. Even after REALLY tightening up the sprocket nut. Im going to have to try the Yamabond on there.

Btw, look how nice and clean you got that. Nice!

Btw, look how nice and clean you got that. Nice!

Daniel - you do really nice work!

I'm comin' down tomorrow so you can do mine while I sit on my duff and enjoy the warm Arizona sun! I'll bring along the BEvERages and the All-Dressed Chips (I don't think you have that delicacy in the US).

Cheers,

Pete

You need to come back Pete, I need a re-do chance to meet you! All Dressed up Chips? I had to look it up!

I thought it must be some kind of poutine thing. Haha

Similar threads

- Replies

- 785

- Views

- 81K