Yes, great video and for you new comers, you can definitely hear the difference in sound as the grit wears down.

2 things: One of my Dad's old tricks was to put a soft spring under the valve that will lift it about an inch. This makes it easier to pull off the seat with the lapping tool as the compound can have an adhesive effect as the seats grind in tighter and smoother together.

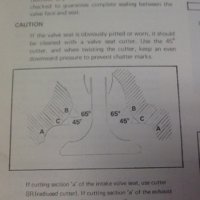

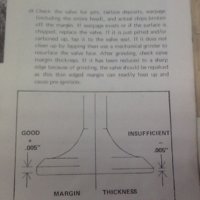

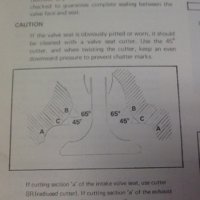

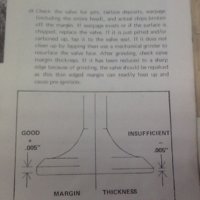

Two: Attached are a few Picts from the xs1-B book that came with my 72. It shows the seat widths and angles that can easily change with mileage and excessive lapping. These figures and angles may have changed thru the years, but they seem pretty basic and straight forward.

I bought a head on eBay, dismantled and lapped the valves and found the contact area was much greater than 2mm. If the contact area is too large, it reduces the seat pressure per square inch. This will lead to burnt valves.

Three: Sorry, sounds like the Spanish Inquisition, anyway, I'm gonna wait to see how my original head and valves look in a week or two and choose the best one.

Lastly, "No one expects the Spanish Inquisition!", my local Japanese bike shop, (and there are several where I live), said that they send their heads to a shop nearby. I spoke to the shop and they said they don't lap, they cut. I'm thinking I'll let them do my head because they'll cut the valves and seats to spec. I will give them my specs. I'm living on a budget also, but for a $100, I know it will be correct and have some confidence that I can maybe get another 60K miles before my next top-end tear down.

That's all I got for now. If anyone has any other specs from newer shop manuals, I'd love to see them.