And at least should prevent squeaky brake . . .

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WTF pictures

- Thread starter gggGary

- Start date

And for anyone thinking this is a one off thing by some back yard wrench:

https://www.wilwood.com/BrakeKits/B...desc=GP310 Motorcycle Rear Sprocket Brake Kit

https://www.wilwood.com/BrakeKits/B...desc=GP310 Motorcycle Rear Sprocket Brake Kit

I hear you, but if you have a chopper….. the goal isn’t performance. Less is more, even where brakes are concerned.Just because somebody makes it commericially doesn't make it a good idea.

Think back to fork-extender slugs.

Still, it's like chlorine in the gene pool.

Grimly, I was not saying it was a good idea or anything of the such just that I knew they existed. I could "almost" see something like that for a belt drive rear wheel as at least would not need to worry about lubed brake pads. Now that I have typed that I actually think I did see someone selling just such a combination belt drive pulley/brake disk! Might do a search on that next!Just because somebody makes it commercially doesn't make it a good idea.

Think back to fork-extender slugs.

Still, it's like chlorine in the gene pool.

Well that only took a few seconds on Google:

https://www.ebay.com/itm/3508242690...5685073768&abcId=9316952&merchantid=137698880

And just for kicks one more:

https://viciouscycleworks.us/Item/pull_rot_bra

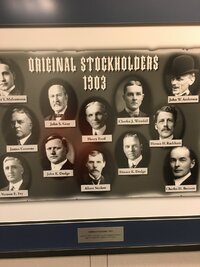

MotorCities National Heritage Area

·On October 7, 1913, Henry Ford’s entire Highland Park, Michigan automobile factory ran a continuously moving assembly line for the first time. A motor and rope pulled the chassis past workers and parts on the factory floor, cutting the man-hours required to complete one Ford Model T from 12 1/2 hours to six. Within a year, further assembly line improvements reduced the time required to 93 man-minutes.

The staggering increase in productivity resulting from use of the moving assembly line allowed Ford to drastically reduce the cost of the Model T, thereby accomplishing his dream of making the car affordable to ordinary consumers. Before then, the automobile industry generally marketed its vehicles to only the richest Americans, because of the high cost of producing the machines. Ford’s Model T was the first automobile designed to serve the needs of middle-class citizens: It was durable, economical, and easy to operate and maintain. Still, with a debut price of $850, the Model T was out of the reach of most Americans. Ford Motor Company understood that to lower unit cost it had to increase productivity. The method by which this was accomplished transformed industry forever.

Prototypes of the assembly line can be traced back to ancient times, but the immediate precursor of Ford’s industrial technique was 19th-century meat-packing plants in Chicago and Cincinnati, where cows and hogs were slaughtered, dressed, and packed using overhead trolleys that took the meat from worker to worker. Inspired by the meat packers, Ford innovated new assembly line techniques and in early 1913 installed its first moving assembly line at Highland Park for the manufacture of flywheel magnetos (pictured). Instead of each worker assembling his own magneto, the assembly was divided into 29 operations performed by 29 men spaced along a moving belt. Average assembly time dropped from 20 minutes to 13 minutes and soon was down to five minutes.

Ford rapidly improved its assembly lines, and by 1916 the price of the Model T had fallen to $360, and sales were more than triple their 1912 level. Eventually, the company produced one Model T every 24 seconds, and the price fell below $300. More than 15 million Model Ts were built before it was discontinued in 1927, accounting for nearly half of all automobiles sold in the world to that date. The affordable Model T changed the landscape of America, hastening the move from rural to city life, and the moving assembly line spurred a new industrial revolution in factories around the world. #ThisDayInAutoHeritage

And if you don't care about brands that flash drive can be had for less than $3.00 before shipping cost on Amazon!

Back in the late 90's I was on a crew that carried all the backup data for Bank of America. They were moving it from LA (Iirc?) to the Caves here in KC.

It was all magnetic tape stored in steel containers. We loaded it on DC-8's and B727's. Don't remember the number of flights it took exactly... about 20 or so I'm thinkin'. Took us 4 days of flying.

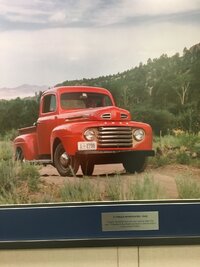

Two weekends ago I went over to the Ford Piquette Ave. Plant which was the original home of Model T manufacturing and is now an excellent museum.

Ford outgrew Piquette Ave. pretty quickly as sales began to take off in 1910 and they moved to a much larger facility at Highland Park MI where the moving assembly line was introduced a few years later spelling the end of "craftsman" manufacturing of mass-market cars.

Anyhow - I highly recommend the Piquette Ave. Plant Museum (461 Piquette Ave., Detroit MI) - the building is still largely original and they have a great collection of cars dating back to some of Henry's earlier creations well before the Model T. As noted in another thread, the other cool place is the Gilmore Car Museum in Hickory Corners MI.

I am also posting some other Model T news in the antique car thread.

Pete

Ford outgrew Piquette Ave. pretty quickly as sales began to take off in 1910 and they moved to a much larger facility at Highland Park MI where the moving assembly line was introduced a few years later spelling the end of "craftsman" manufacturing of mass-market cars.

Anyhow - I highly recommend the Piquette Ave. Plant Museum (461 Piquette Ave., Detroit MI) - the building is still largely original and they have a great collection of cars dating back to some of Henry's earlier creations well before the Model T. As noted in another thread, the other cool place is the Gilmore Car Museum in Hickory Corners MI.

I am also posting some other Model T news in the antique car thread.

Pete

Honey did you borrow my ratchet?

1st thing I thought of...Betcha that's a 10mm socket on there...

(I have to stay on this forum 24/7 to try to keep up with youse guys..)

Yeah, Ford's assembly line was inevitable, but the way he used it was brutal.

(I am a proud retired member of IBEW Local 520.)

Wow! Spectacular image of a rift valley, @gggGary.

There's a rift right across Iceland formed as the European and and N American tectonic plates drift apart.

Read somewhere that America and Europe are moving apart at about the same rate that fingernails grow. Just one of many useless facts that clutter my mind.

There's a rift right across Iceland formed as the European and and N American tectonic plates drift apart.

Read somewhere that America and Europe are moving apart at about the same rate that fingernails grow. Just one of many useless facts that clutter my mind.

Not so much a wtf picture, as a wtf article.

Hey, donkey; leave that moose alone.

https://ca.news.yahoo.com/bystander-captures-instant-karma-moment-093000756.html

Hey, donkey; leave that moose alone.

https://ca.news.yahoo.com/bystander-captures-instant-karma-moment-093000756.html

When you split the cases and see this you have to say WTF

Similar threads

- Replies

- 785

- Views

- 81K