Ha-ha, took me a while to figure that one out...Like how the tread runs down the sidewalls...........

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1973 Super Rustbucket Resurrection

- Thread starter DogBunny

- Start date

Full disclosure, this is pretty much what I really planned on all along. Was just afraid to say so...Could make sure there's oil in there and just let 'em leak. More "rat" appeal.Just top it off every few months... or when it starts bouncin'.

only 2 weeks............they will be calling you, quick draw Magraw.....

Now, the new literature says to remove the old Kreem liner using a paint remover containing Methylene Chloride. Methylene Chloride was removed from consumer paint removers a few years ago -- I considered stocking up on it when I had the chance, but I never did, which I regret. Caswell will sell you Methylene Chloride paint remover, but you have to jump through some hoops for them, and it is expensive. Anyways, there is no way in the world that I am removing the Kreem liner. I'll apply the Caswell on top of it, as I have always done.

They also offer some new colors now. I chose Battleship Grey.

I'm not 100%, but I believe acetone will remove a Kreem liner. I had a grey liner and I tried the paint stripper. It didn't touch it. Acetone made short work of it.

Here's the link to my thread on another forum: Failed Tank Liner

MEK (Methyl Ethyl Ketone) is another solvent for some liners.Now, the new literature says to remove the old Kreem liner using a paint remover containing Methylene Chloride.

Of course, because it was good at the job, it was banned.

It isn’t banned here, at least not the last time I checked. I think acetone does the same job, although not as quickly.MEK (Methyl Ethyl Ketone) is another solvent for some liners.

Of course, because it was good at the job, it was banned.

I may have to find out if that is true.I'm not 100%, but I believe acetone will remove a Kreem liner.

I used Kreem in my Hurricane tank 30 years ago. To be honest I have not looked in it yet. Tanks the last to go on.

So, I finally did some work on the RustBucket.

This is what I worked on. That first pic was just a teaser/reminder of the patina that I'm working with. I intend to do the absolute minimum aesthetic-wise on this bike. But, since it is almost 100% complete and intact, I at least want to repair the "Swoosh" trim on the right-side cover. How I fixed a broken Swoosh, with way too much detail and way too many pictures follows.

First, let's back up and explain why it has taken me so long to do anything on this project. I began the Bonded Title application way back in the very beginning of December, 2020. Texas has been progressively making it harder and harder to get bonded titles for years. It used to be that if the state had no records of your VIN, all you had to do was go to any vehicle inspection station (there are thousands of them), and get the inspector there to visually verify your VIN. But, now, you have to go to the Sherrif's Combined Auto Theft Task Force to get your VIN verified. Each county has only one of these locations.

Well, even though the RustBucket is a Texas bike, it has been so long since it was last registered, that it pre-dates computer records. In other words, the state had no records of the VIN, so I had to go to the County Sheriff. This is a hoop that I have never had to jump through before, and I've probably gotten about 20 Texas Bonded Titles.

I applied at the beginning of December for an inspection appointment. Finally got an appointment for the end of December. Then, two days before my appointment, it was cancelled due to COVID. That inspection moratorium lasted FOUR months. The Sheriff's finally resumed inspections two days ago. I now finally have all of my bonded title paper work. I just have to pay the usual registration and taxes -- my appointment for doing that is three weeks from now.

In any case, my bike is green-lit, it isn't stolen, so I'm finally working on it.

No, I don't have a way to replace that big chunk of missing "Swoosh" from the RustBucket's right-side cover. But, I am able to repair plastic cracks and plastic mounting posts. Some time ago, I was removing a swoosh from a different side cover. I was prying off the little round "push-nuts" on the posts with an angled pick. This is a fine procedure if your badge or emblem is metal. However, never, EVER pry off push-nuts from a plastic trim piece. Don't do it! Especially when the plastic is 50 years old! The only safe way to get them off is to cut them off with a Dremel cut-off wheel. And, you want to do this with plenty of cooling water present so that you don't melt the plastic post. It's probably a good idea to make sure the Dremel is on a GFI protected circuit.

So, as I'm sure you've guessed, using the angled pick tool, I broke a mounting post. I should have taken a picture before I began the repair, but I didn't.

Not only did the post break, but the tip of the swoosh cracked. It is just barely hanging on by a thread.

Now, at this point, there are two ways to proceed. One way would be to mount the Swoosh using the good posts, and simply gluing the cracked section directly to the side cover. This would be the Easy Way. But, it wouldn't be the Cowboy Way. I like to explore what is possible, so I chose to see if I could replace the post and repair the crack.

I found this minuscule screw in my Big Bin O' Tiny Nuts and Bolts, and I cut the head off of it.

Intact posts are hollow, as you can see from the post on the right. There was enough of that hole left for me to insert the screw after I enlarged the hole a little. I know had a perfectly centered new post that was stable enough to apply Epoxy. I also added a piece of glass cloth to reinforce the crack in the Swoosh. The glass cloth is over-sized so that I can handle it. It will be trimmed after the epoxy sets.

I think my original idea was to use a nut of some sort, maybe a tiny speed nut, on the tiny screw, but I didn't think I would ever find anything that small that would work, so the plan changed.

This is what I like. I used it plain and runny on the glass cloth. I needed to thicken it on the post repair, so I added the 405 filler. BTW, the West System is specifically designed for wooden boats, so their various fillers all turn the clear epoxy brown, or wood-colored.

The almost-finished post after a second application of epoxy. The epoxy was thickened, but still runny enough to shape itself to the screw with surface tension. I had to periodically flip the piece upside-down while the epoxy set to get it to stay where I wanted it, because it ran just a bit.

I've done a bit of final trimming using an abrasive Dremel bit.

Almost done. I still had to do a little bit of final Dremeling while fitting the new push-nut.

https://www.amazon.com/gp/product/B07M6JPG68/ref=ppx_yo_dt_b_asin_title_o06_s00?ie=UTF8&psc=1

Onward to the push-nuts, AKA starlock washers, AKA internal tooth washers, AKA push-on speed clips, etc., etc. There are lots of fairly spendy options for these, but I foresee a lot of Swoosh and other emblem fastening in my future, so I bought these. 100 pieces for $7.

Problem is, these are advertised as M4, but I don't know how the heck they are measuring them -- they are way too small for an M4 stud, or screw, or rod, or post.

https://www.amazon.com/gp/product/B07JD8H2DX/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

So, I went up to these M5 starlocks. These were specifically advertised as having a 4.3mm I.D. Again, I don't know how the heck they are measuring them, but the I.D. was a lot bigger than 4.3mm , and these were unusable. I got my money back from Amazon, got to keep them, and I went back to the M4 starlocks that I bought the first time.

The trick now was to enlarge the I.D.s of those M4 push-nuts using the Fred Flintstone Tool Kit available to me.

Using a drill bit as a holder...

... I chucked them up into a BFDM.

https://www.harborfreight.com/titanium-high-speed-steel-numbered-drill-bit-set-60-pc-61690.html

And I incrementally enlarged the I.D. using a second drill motor and the above Harbor Freight numbered drill bit set, a marvelous bit of kit that I don't know how I ever got along without.

This was pretty tedious. Thank goodness for quick-change key-less drill chucks.

The factory put little rubber "gaskets" under the push-nuts. I made new cork-rubber gaskets using my old gasket cutter.

https://www.amazon.com/Mayhew-66002-8-Inch-2-Inch-Imperial/dp/B000X35UQ8

My gasket cutter kit is a knock off of this one. I bought it way, way back, in order to make the gaskets for my ThermoDipSticks. The mandrel can hold two different cutters at the same time, so you can cut a complete circular gasket in a single step. I think I only paid $60 for my kit. I haven't seen the knock-offs offered for sale in years.

Repaired post at the bottom, Swoosh installed with all new push-nuts and gaskets.

All better now.

Another view.

The little crack.

The fitment gap is exaggerated in this enlarged picture. It's good enough for the RustBucket, and I did it the Cowboy Way.

Nicely done!!

I'm still diggin' the pinstripes.

I'm still diggin' the pinstripes.

Great job saving that plastic emblem! I can attest to how brittle they are. I tried cutting those push nuts off with my Dremel and still managed to break a couple. What a hassle getting your title straightened around. I’ve never been brave enough to buy a non titled bike!

Nicely done!!

I'm still diggin' the pinstripes.

Yes, we know why Jim likes the pin-stripes...

The pin-striping is a combination of professionalism and old-school weirdness, the likes of which I have never seen. The artist definitely was practiced, used the proper tools, knew what he was doing, and was proud enough of his work to sign it. But, who pin-stripes cross-hatching? Has anyone ever seen that? And how about the little orange dots added at the end of the long strokes? Also done on the side covers and headlight. An unusual detail, and a strange third color choice.

The sheriff's inspection was free, the DMV bond application was $15, and the insurance company's bond was $100, so the bond adds $115 over a normal title transfer. I was pretty sure of the provenance of this bike, so buying it wasn't a huge risk.Great job saving that plastic emblem! I can attest to how brittle they are. I tried cutting those push nuts off with my Dremel and still managed to break a couple. What a hassle getting your title straightened around. I’ve never been brave enough to buy a non titled bike!

Preparing the rear wheel for new rubber.

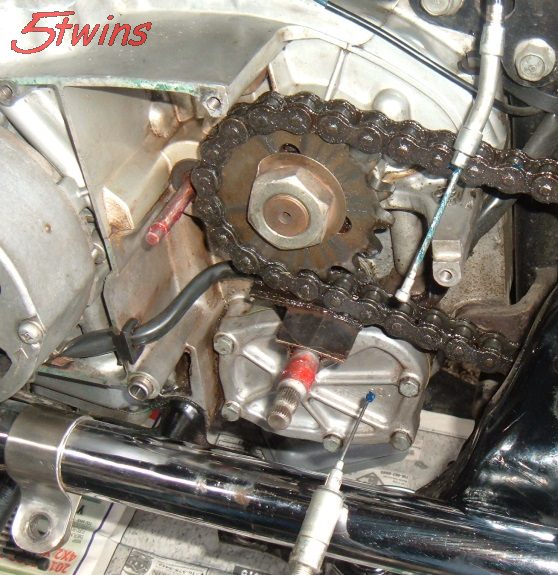

The wear on this sprocket makes more sense if you know that it is aluminum. What makes less sense is that the folding tab "lock-washers" appeared to be original and unmolested. It's correct, stock 34 tooth, 530 size. Is it possible that 1973 bikes came with aluminum sprockets???

Credit goes to 5twins for this. It's easy to pop off sealed bearing covers that are plastic in order to re-pack the wheel bearings. Steel covers are trickier. I've done this a couple of times, and you get better with practice. You need a super-thin prying tool. I like a teeny, soft steel screwdriver that you hammer flat to a knife edge. Works better than an actual knife. Pry from the center. You WILL distort the cover.

Re-grease using a grease gun and a grease needle to get under the bearing cage. Again, thanks to 5twins.

BTW, has anyone else noticed that the factory used brown grease? It makes it look like the bearing has become rust contaminated.

Here I have replaced the steel cover after getting it back in shape using large sockets as hammering dollys. When you tap it back onto the hub, you have to be very careful that you don't tap it in too far, or it will rub on the bearing cage. Easy to do, and then you have to start over.

Note that the grease seal also got distorted when I pried it off. A steering bearing race, shown at the top of the pic, makes a prefect dolly for getting the grease seal straight.

The finished, serviced wheel bearing. Who's to know?

Tires just arrived today.

https://www.amazon.com/gp/product/B0059HJKQ4/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

This grease needle is only $3.40.

Last edited:

Is it possible that 1973 bikes came with aluminum sprockets???

My low mileage XS2 was as original as could be, right down to its tires, and it had a steel sprocket.

Yeah, I figure the aluminum sprocket can't possibly be original, but the "lock-washers" sure looked original and unmolested. Maybe someone had access to a factory lock-washer tab folder-overer. I'd sure like to see that tool...

I love those grease needles. Here, I've used it to inject grease into my clutch cable elbow .....

Just recently, I started cleaning and greasing the lips on my wheel seals. It just dawned on me that they rotate with the wheel around the spacer that fits into them. Seemed like a good idea to fill their seal lips with grease.

Just recently, I started cleaning and greasing the lips on my wheel seals. It just dawned on me that they rotate with the wheel around the spacer that fits into them. Seemed like a good idea to fill their seal lips with grease.

Looks like your using Bel-Ray grease in cartridges. I'm going to stop buying the tubs, and I'm going to get a dedicated grease gun for the Bel-Ray.

Good point on the spacers. They are always greasy where they fit into the seal. The pressed-on dust covers, on the other hand, appear to be designed to not actually make contact with anything, and are always clean.

Good point on the spacers. They are always greasy where they fit into the seal. The pressed-on dust covers, on the other hand, appear to be designed to not actually make contact with anything, and are always clean.

No, actually I use Kendall Super Blu. My dealer turned me onto it years ago. It's a very good general purpose grease and very waterproof. This makes it popular with boaters, for their boat trailer wheels (since they're always backing them into the water) .....

I hear you about dedicated grease guns. Once you start a tube in a gun, there's no changing it to something else without making a real mess, lol. So, I just buy more grease guns. I finally built a rack on the wall for them. My new favorite is the one on the left. It's a flex hose type with a pistol grip. You can operate it one-handed. It's got the Kendall Super Blu in it .....

I hear you about dedicated grease guns. Once you start a tube in a gun, there's no changing it to something else without making a real mess, lol. So, I just buy more grease guns. I finally built a rack on the wall for them. My new favorite is the one on the left. It's a flex hose type with a pistol grip. You can operate it one-handed. It's got the Kendall Super Blu in it .....

In 2020, there was a thread on Grease guns. Decent thread, but it only lasted for 17 posts:

http://www.xs650.com/threads/grease-guns-wtf.57798/

I'm sticking with what I said back then: after lots of frustration, I finally shelled out for a decent grease gun from Napa. All of the other auto parts store grease guns are toys. And, what's up with all of the liquid that separates out of an opened cartridge over time??? (I don't expect the blue Bel-Ray or the blue Kendall to separate.)

http://www.xs650.com/threads/grease-guns-wtf.57798/

I'm sticking with what I said back then: after lots of frustration, I finally shelled out for a decent grease gun from Napa. All of the other auto parts store grease guns are toys. And, what's up with all of the liquid that separates out of an opened cartridge over time??? (I don't expect the blue Bel-Ray or the blue Kendall to separate.)

Rear rim, outside. This is the worst spot. Big chrome flake.

Rear rim, inside. Not that bad. This is the worst spot. I've seen WAY worse.

Exact same spot after wire wheel.

Put wheel on truing stand. Very true. No loose or bent spokes.

Steel brake lining in the hub good, just cleaned it up a bit with 220 grit silicon carbide sandpaper. Brake shoes good, used same sandpaper to de-glaze them.

Greased the splined brake plate lever camshaft. It was very dry.

Took the opportunity while the rear wheel was out of the frame to remove and grease the splined rear brake pedal pivot shaft. No convenient zerk fitting on it like on later years. It was very dry. In the process, I broke the threaded plastic part of the rear brake light switch. Found a replacement switch and made better.

Found a rear sprocket with good teeth and the appropriate patina to replace that badly worn aluminum sprocket. Re-used the old bolts and lockwashers.

My new rear tire on my beautiful RustBucket. The rear inner tube looked good enough to me, so I reused it. The rim strip looked good, so I flipped it over and reused it. As previously mentioned, I reused the wheel bearings and seals.

Did all this work, and the only new part was the tire (and fresh grease). And, two parts got replaced with used parts, the rear sprocket and the brake light switch.

Similar threads

- Replies

- 61

- Views

- 2K