Well.....while I sort out my cam and rocker woes....I'll can get back to our feature presentation with a few more pics of what I got up to Sunday.

Pulled the head and jug off....turns out it doesn't take a real long time to get pretty filthy in there...gonna have to give those gasket surfaces a good clean.

At this point I realized the reason Jim's top-end thread is so great (and why I had a similar experience last year w/ my rebuild) is because he's starting with perfectly clean parts and leaving out the part that !*#$& sucks. Here's some very unglamorous pics of me stuffing the open motor w/ shop towels and scraping gasket remnants off the cases with a plastic scraper blade and Permatex gasket remover. It probably took 20 minutes or so and one of many grimy scraping jobs of the day.

Ok....new BBK gasket on my nice new clean mating surface.

Here are a couple that I thought were interesting showing the stock OEM jug next to the BBK.

Next one is pre-installing my Hoos cam-chain front guide (with some crappy HW

). Centered within the tunnel to < 0.5mm tolerance which seemed plenty when I mocked up and eyed the width of the chain on the guide.

Forgot to take a pic, but I then pre-installed the pistons in the bores with the jug upside-down from the bottom. Lots of posts here and in the manual for ring gap orientation, so won't rehash that. Made sure to install the interior circlips on each piston as well.

Ok, so something I did find that was a little surprising....I don't know if it was just my kit, or play in my studs....but I actually had a bit of trouble getting the BBK jug onto the motor. It seemed to hang up on the threads. Whether it was the tolerances of the kit, or maybe my threads were splayed out from years of use, I don't know. It could move by hand but was just really snug and would bind every time I tried to push it down (almost felt like it was sort of cocking left, then right). I think the 8 individual points of movement amplified this 'cocking' effect. In any case, I ended up adding some assembly lube to the studs (although grease may have been better) and very lightly tapping left/right to get it on. I was concerned about this damaging something but I could feel it sort of 'wiggling' down the studs each time I tapped it, so I just stuck with it. It ended up taking longer than you might think, but it got on there eventually and I hand threaded a nut on each stud successfully, so I didn't damage any threads.

At this point I used whatever ridiculous combination of handy items (dead-blow handle and random block of wood) to position the jug so that I could get the wrist pins in. While I don't show it here, be sure to put those shop towels back into the motor when installing the other circlip...it's tempting fate otherwise...

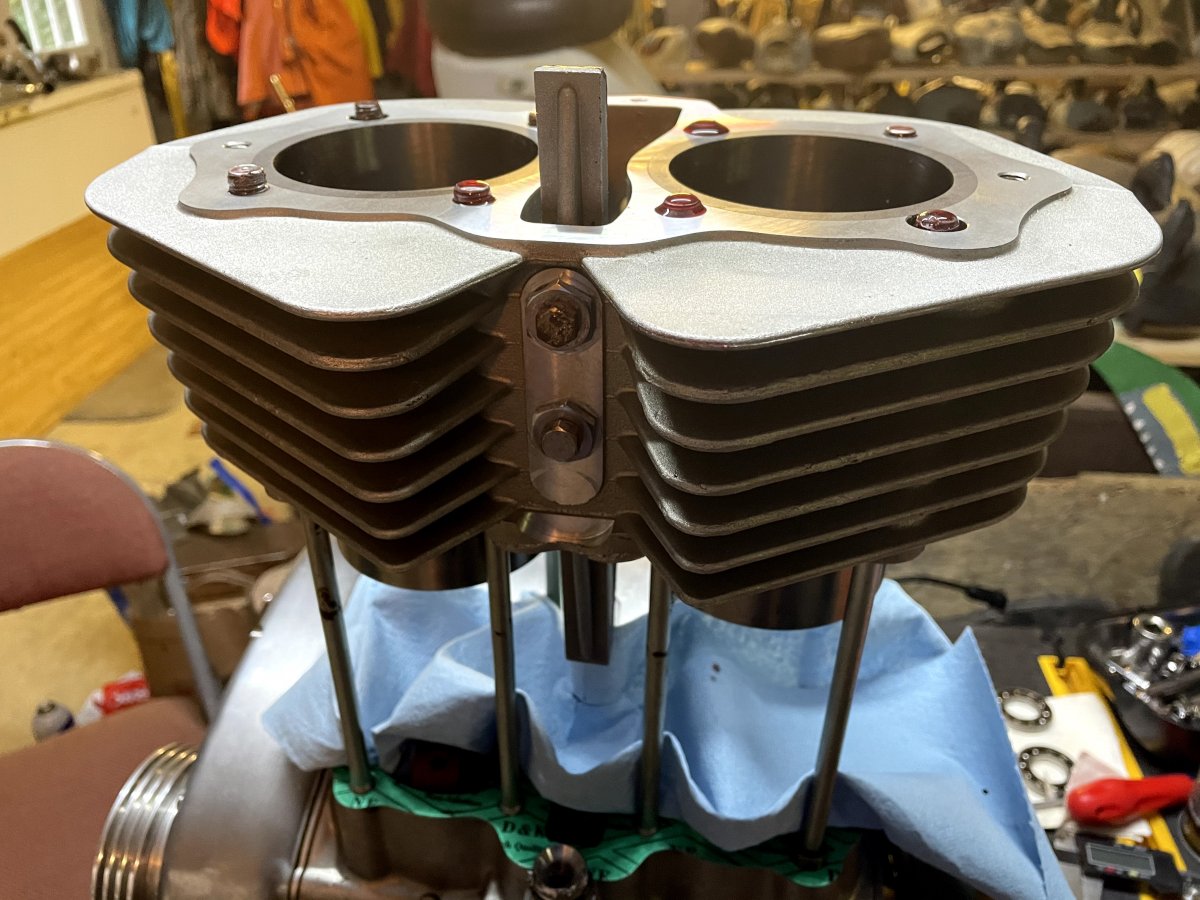

And with that, BBK jug and pistons installed.

@jim

@jim