Bike wont start?, Running rough?

First: What have you just done? What have you changed? Has anything odd or different happened? Any new strange noises? Just bought it? Heard it running? Riden it? Been sitting?

new purchase? been sitting? before you even kick it over…

freaking yet?...dont worry, be happy…its all cheap insurance and helps you get to know your new friend, look after her and she’ll return the favour

cold set

before running do a cold set..

.

still wont start?

ignition problems

- a very interesting site for TCI ignitions , covers this way better than i ever could

only now should you contemplate looking at your carbs, this is the second to last step, the last being synchronisation

...these carb readings are worth the effort, esp this for the CV carbs and this for VM34-36 ... read and reread until youre dreaming the stuff

...go here for dell'orto carbs

...this isnt finished...carb syncing to follow...feel free to rip this to pieces, neither complete nor perfect...so, at it - fix it for me...i will be interested to see what you think ive done wrong

First: What have you just done? What have you changed? Has anything odd or different happened? Any new strange noises? Just bought it? Heard it running? Riden it? Been sitting?

- just bought it, well, don’t believe anything the PO has told you, ignore it

- already your ride, you will already have a connection with this old girl, listen to your instinct, trust yourself? Ok…consider these anyway…

- 3 things all motors require - power, fuel, air

new purchase? been sitting? before you even kick it over…

- get a manual

- check tank..rusty? empty, clean it properly, including petcocks tank cap-seal and air vent

- replace inline filter, if none put one in

- check and clean air filter, replace if necessary

- drain carbs, if the fuel stinks or smells odd, remove and clean, thoroughly…if it smells normal, you might be lucky, can be worth the chance in the short term but you wont get away with it forever

- if your inlet manifolds have vacuum barbs, check the rubber caps for cracks and fit

- if carbs are off, check the rubber intake mounts, they get hard and crack, replace with good ethanol resistant ones, don’t forget the boots connecting to the air filters, they get old and brittle too, replace if necessary carb guide

- check your throttle and clutch cables, if not teflon lined clean and lubricate, if teflon lined check they slide freely, if not replace

- while the lhs side case is off, check the clutch worm drive, don’t lose the ball bearing, clean the worm well, the worm-case can crack and expand when you pull the cable preventing proper operation, pack with grease-don’t forget the ball bearing, don’t reinstall the side-cover yet

- do a compression and or leakdown test, see below...

both cylinders should be within 10% of each other

under- 100 psi poor

100/125 psi good

125/150 psi excellent

both cylinders should be within 10% of each other

under- 100 psi poor

100/125 psi good

125/150 psi excellent

- drain the oil, smells of petrol? the carbs have been leaking-floats are holed or not set properly or the float needle seat is compromised or the float needle o-ring is damaged, check and clean the filter screen as well

- check the oil, look for pieces of black plastic from the cam chain guide, it will need replacing, also alu pieces, normally cam chain hitting the case, sounds awful, hopefully it hasn’t reached the bearings, large bits may be 5th main gear or 3rd pinion gear dogs, crank bearing cage pieces have been found, also broken clutch primary springs

- check the suction-side sump filter, these break- oil filter thread

- check the pressure-side side filter, it can be washed, I prefer to change it

- fill with oil

- get help, bike on main stand, rotate rear wheel while going through the gears, 1 at a time, gives a feel for possible gearbox problems

freaking yet?...dont worry, be happy…its all cheap insurance and helps you get to know your new friend, look after her and she’ll return the favour

- ready to go?..uh uh…not yet mate

cold set

before running do a cold set..

.

- is your battery charged

- rotate engine counterclockwise to tension cam chain, adjust the tensioner so its flush, lock the backing nut...recheck when hot

- remove the lhs side-cover, bike out of gear, remove a plug, if you have a TDC finder….install it, if not, a plastic straw or knitting needle will do-put it in the hole so you can feel where the piston is, rotate the flywheel ccw, 17mm socket-for control-feeling for TDC, you will probably need to go round several times to get the feel, if you go over don’t rotate back, go around 1 more time so the tension is on the back of the chain

- now set the tappets, remove covers, rotate crank feeling for the top of the compression stroke, where both tappets are loose on the cam

- set tappets - model...inlet...exhaust

...XS1-B.....0.003"(0.076mm)...0.006"(0.15mm)

...XS2-650..0.006"(0.15mm)....0.012"(0.30mm)

...XSB........0.0024"(0.06mm)...0.004"(0.10mm)

...XSC-on...0.0024"(0.06mm)...0.006"(0.15mm)

- rotate for the compression stroke on the other side and set those tappets too

- install new plugs, gapped, N7Y champion or BP7ES ngk ... 0.027-0.031" (0.7-0.8mm)

- if you have points, check the advance mechanism, pull the rod, clean and lubricate it, check the weights, make sure they move freely and arent loose, check the springs-the weights should snap back fully, if not shorten the springs-even better replace… video atu

- static set the points…key on, use a small 12v bulb, key off, use an ohm meter, first one set of points, then the other

- set them at the highest point of the points cam lobe 0.012-0.016" (0.30-0.40mm) against the points rubbing block

- rotate crank counterclockwise, the light or meter will show when the points open…keep in the same field of vision, next to the timing marks, easier observation, allows you to get the timing almost spot-on, recheck when running with a timing light…for greatest dwell angle set for smallest gap possible…advance with larger gaps, retard with smaller gaps

- time the rh cylinder-upper points set by rotating the complete backing plate

- time the lh cylinder-lower points set by moving the half plate only

- points opening before ‘F’ are advanced-opening early

- points opening after ‘F’ are retarded-opening late

- timed, motor running, BTDC 15° @ 1200rpm

still wont start?

- flat battery

- this is not necessarily the carbs, its easy to waste time on them when youre really chasing an electrical problem, check for spark by rotating for closed points, open them manually-you should see the spark, a good one should be blue and about 6mm

- no spark…condenser, replace…dirty electrical connections...kill switch, coils, plug-cap-lead, TCI

- burnt points...condensor

- kicking back...atu

- weak spark…coil, leads, plug caps

- intermittent spark…broken power feed to points, check behind the points plate…coil, test when hot...broken solder connections in the TCI, resolder…dirty electrical connections, check them, clean, use dielectric grease to seal them-1 at a time

ignition problems

- fuses, kill switch, batt terminals, ignition switch, dirty connections

- worn, burnt or pitted points

- worn points rubbing block

- points plate off centre or not seating correctly

- worn points cam

- broken points wires

- points or atu cover seals leaking

- condenser kaputt

- coil kaputt

- TCI kaputt, TCI pickup kaputt

- side stand relay-if fitted

- atu return springs too long or weak

- atu shaft not lubed or worn bearing surfaces

- atu shaft pin broken-shouldn’t rotate more than 40°

- a very interesting site for TCI ignitions , covers this way better than i ever could

only now should you contemplate looking at your carbs, this is the second to last step, the last being synchronisation

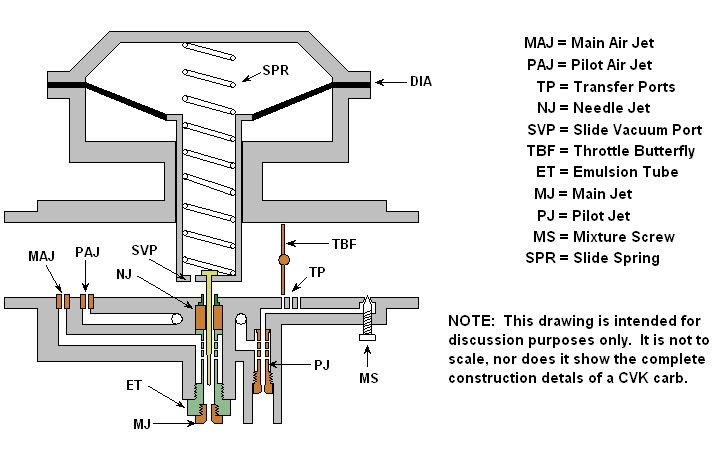

- as far as the carb is concerned there are 4 main operating functions that affect fuel delivery at various stages... ...0-100% throttle...pilot air screw/jet , 6-50%...slide cutaway, 20-85%...needle jet/jet needle, 33-100%...main jet

- most problems stem from blocked primary circuits, thus affect your idling, your bike wont idle when these are blocked

- fuel must come out the 3 tiny holes in the throat...use a small guitar string bent in an L to gently probe the 3 holes as you spray - cover the other holes with your fingers to increase spray pressure...when spray comes out the 3 holes they are clear

- set the mixture screws...see the table at the end of the carb guide p 27 ...hat-tip weekendrider

- set each side at operating temps for light-black/grey 1/3 the way up the electrode

- set each side mix screw independently for plug color...rhs runs 25 degrees hotter, requires more fuel

...these carb readings are worth the effort, esp this for the CV carbs and this for VM34-36 ... read and reread until youre dreaming the stuff

...go here for dell'orto carbs

...this isnt finished...carb syncing to follow...feel free to rip this to pieces, neither complete nor perfect...so, at it - fix it for me...i will be interested to see what you think ive done wrong

i love forums, you cant get away with forgetting anything...

i love forums, you cant get away with forgetting anything...