This may be a little long and hopefully not too convoluted.

Took the rocker cover off and as I expected cam is late. No big surprise. I was convinced it would be a tooth off. It's not. Hard to see in the pic, it's not a full tooth off. I removed the cam chain adjuster so the can has all it's slack. Then set crank to TDC. Moving the cam each direction by hand until the slack is gone backs the mark of equal a amount from where it should be.

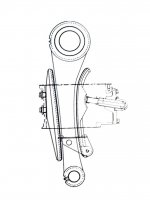

Looked at rockers. They show a bit of wear, I can feel that slight flat spot with my finger. I do think they are a contributing factor but no smoking gun. For all 4 or even 2 to wear at the same time to the point of causing a severe compression drop is a stretch.

The discoloration on the rocker is a reflection.

Looked at the cam, no flat spots on it. Looks OK. Camera makes it loose worse than my eyes.

Thinking cap and more coffee time.

I'm convinced that late cam timing is causing the problem. Increasing the valve clearance from 3 to 6 nd getting back to the compression I had before the Ozark to me proves that. I'm thinking the combination of the chain stretch and the wear on the rockers is the cause. New cam chain and better rockers it should be good to go.

What kept bugging me is how did all this happen at once on a engine that had just been sitting. I then had a eureka moment where it all came together, even the cause of this mess.

Think about it .003 increase in valve clearance increased the compression from 25 to 125. I don't think .003 at the valve tip can be that much in relation to cam timing. If someone wants to figure it out go ahead. I think I would get a headache trying to. Anyway the cam chain stretch must have been right at the tipping point of causing this. What changed to tip over the apple cart. When I said in the beginning of this thread all all I had done to it was clean and service it. Service had consisted of cleaning carbs and oil change, neither should cause this. Well I did one other thing which could. Didn't mention it because I didn't think it was relevant. I noticed on the trip back my base gasket was seeping a little oil. What is the recommended thing to do with a seeping base gasket. Re-torque the head. I had done it at 500 smiles, figured it was due. I'm thinking re-torquing compressed the head and base gasket just enough to tip over the apple cart. Any more compression of the gaskets is the same as chain stretching. I know the amount of chain stretch would be half of compression.

My plan is to replace the cam chain, base gasket and rockers. I have a used set of rockers that look great.

Now what caused the cam chain to stretch, rockers to wear and base gasket to leak plus an odd clutch problem. One of two things. One could be my brothers spirit, would not put that past him. The other is oil. Last summer I switched from all VR1 to 1500ML of 20W50 Wally World oil with the rest VR1, then adding VR1 as needed for make up. I'm going to blame Wally World. Switching back to 100% VR1 fixed the clutch issue.

That's my story and I'm sticking to it. Unless someone shoots holes in it.

I did put the adjuster back in and set it. From the face of lock nut to the end of the adjuster measured 10.53 mm. Just thought I would throw this out there. This is a 256 adjuster. Be interesting to hear from other guys with them what theirs measure.