It might be worth noting that not all motorcycle frame designs use the swingarm bolt as a pinch bolt to draw the frame together at the pivot. IMO flexing at the pivot is the main reason for the bolt breaking at the threaded section. The 500 thumpers have the same design issue.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swingarm Play (pivot bolt damage)

- Thread starter jetmechmarty

- Start date

On my tracker frame I first put zerks in the swingarm, I later welded them closed and instead put zerks in the ends of the pivot bolt and cross drilled it where the bushings are. Much easier to access.

It’s an interesting discussion and fine by me if it continues. However, since I’ve been riding this thing this long, I’m going to go with the bronze I have on hand.

I remain suspicious of the bronze bushings not receiving grease due mostly from the difference in grease tracks between the OE and the aftermarket bushings.

I remain suspicious of the bronze bushings not receiving grease due mostly from the difference in grease tracks between the OE and the aftermarket bushings.

Marty I‘m curious how much play there was and how did you notice it was there? Did you need to disassemble the suspension to notice the play?It’s an interesting discussion and fine by me if it continues. However, since I’ve been riding this thing this long, I’m going to go with the bronze I have on hand.

I remain suspicious of the bronze bushings not receiving grease due mostly from the difference in grease tracks between the OE and the aftermarket bushings.

I could feel it in the corners. Pumping it full of grease fixed it……. for a minute. On the center stand, I could grab the back of the tire and feel it without a doubt. It was obvious. Disassembled, it’s less obvious, but the pivot bolt has play in it.Marty I‘m curious how much play there was and how did you notice it was there? Did you need to disassemble the suspension to notice the play?

Arctic, to answer your question, that particular kit was not designed to take thrust loads on a bushing flange and a thrust plate (AKA grease seal), preventing lockup with an inner bushing ("tube") long enough to maintain clearance between nylonor bronze outer bushing flange and torque plate. One more time: Thrust load in that particular kit, which Mike's sold back in the early 90's, is taken up by sealed needle thrust bearings which replace the OE thrust plates. There are no thrust plates for a longer "tube" to engage. The fatter, shorter tube in the kit engages the needle thrust bearings. The needle thrust bearings can survive no more pressure than what is applied by tightening the swingarm axle to 25 ftlbs. 25 ftlbs is not enough to stabilize the frame at the swingarm pivot. Needle bearings in that locatiion provide no advantage over bronze bushings anyway. To sum up, the kit is not defective, it's simply wrong for frames in which the swingarm pivot requires adequate pressure to avoid excessive flexing.

Just to throw another grease solution out there....

The stock steel pivot tube already has grooves cut inside it for a grease path, at least mine did. Since it has plenty of meat to it, I went ahead and cut channels around the outside of it too.

Just the two zerks on the bolt... and grease makes it's way out to the bushings pretty easy now.

The stock steel pivot tube already has grooves cut inside it for a grease path, at least mine did. Since it has plenty of meat to it, I went ahead and cut channels around the outside of it too.

Just the two zerks on the bolt... and grease makes it's way out to the bushings pretty easy now.

Something to consider when you put it all back together Marty. The newer frames seem to have a bit more clearance across the mount bosses than the earlier frames. You actually want an interference fit across the pivot tube, otherwise the majority of your bolt torque is used up just sucking the frame together against the pivot tube.... which I'm guessing yours wasn't.

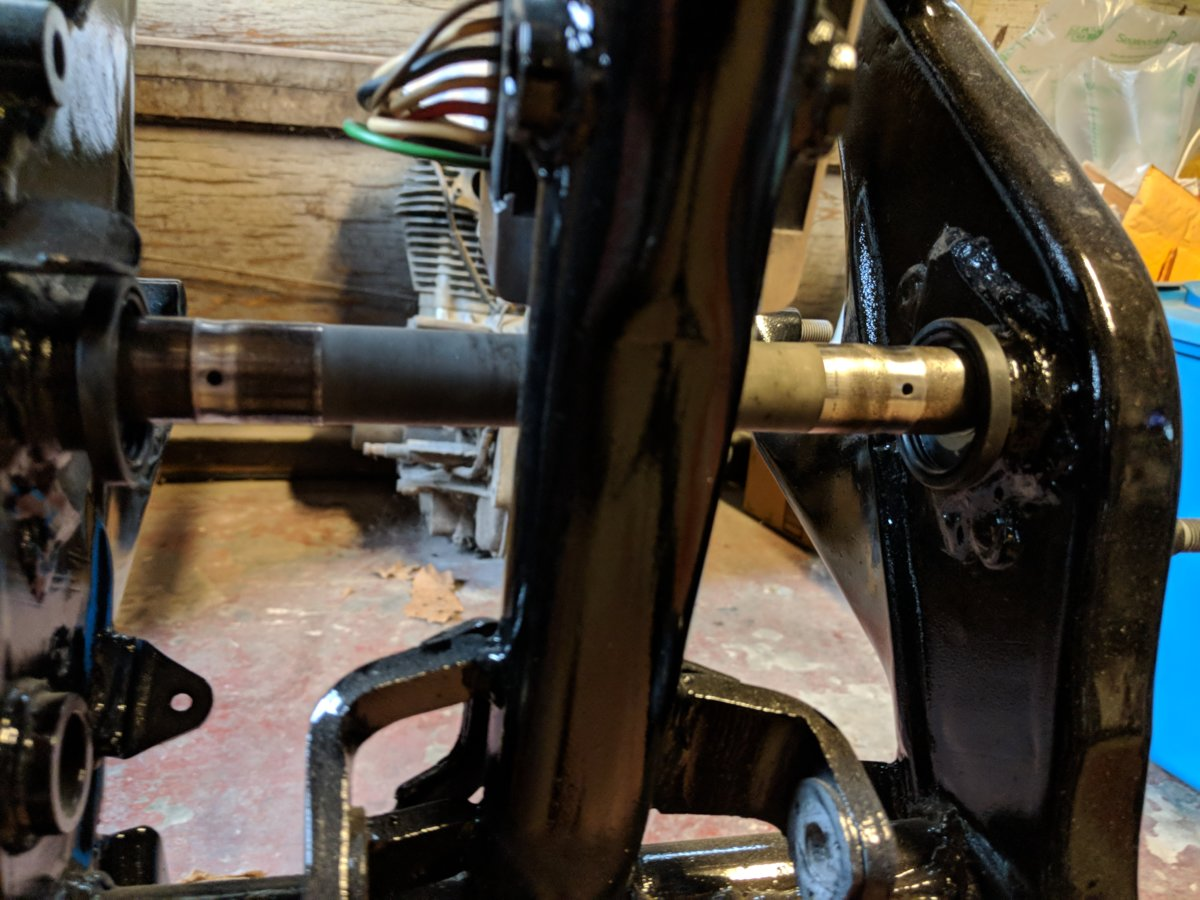

Use a washer with an ID the same as the bolt on the outside (outboard) of the grease seals as a shim to take up the slack so you get an interference fit. Here it's installed without the through bolt... just an interference fit holding the seals and pivot tube.

That washer was about .065" thick iirc.

Use a washer with an ID the same as the bolt on the outside (outboard) of the grease seals as a shim to take up the slack so you get an interference fit. Here it's installed without the through bolt... just an interference fit holding the seals and pivot tube.

That washer was about .065" thick iirc.

Marty, 5twins and Jim have both posted good procedures for ensuring grease feed. I've followed Jim's drill, and it works great. Look for it in Yamadude's thread of Dec. 24, 2017.

Yes, I have the Yamadude thread bookmarked.

I have .010 inch clearance on each end and a .040 inch grease track on each end. It’s going to have to warm up outside before I can paint it black.

What's on there now, primer? I never saw it that color.

Yes, your pivot sleeve mod should allow grease to enter the grease "swirls" in your new bronze bushings easily. I'd still put the extra holes through the center though.

Yes, your pivot sleeve mod should allow grease to enter the grease "swirls" in your new bronze bushings easily. I'd still put the extra holes through the center though.

Yeah... zinc chromate or phosphate. Every hanger I ever worked in had cans of it at pre-pick stations. Occasionally a can would randomly fall in my lunch box. Weird huh? I still have a few cans laying around.What's on there now, primer? I never saw it that color.

I'm guessin' Marty's lunch box was as unlucky as mine was.

Even better than that! I got a professional job, but they weren’t motorcycle mechanics.Yeah... zinc chromate or phosphate. Every hanger I ever worked in had cans of it at pre-pick stations. Occasionally a can would randomly fall in my lunch box. Weird huh? I still have a few cans laying around.

I'm guessin' Marty's lunch box was as unlucky as mine was.

You aren't kidding! I have over 1/8 in of play, or 0.129". I sourced a washer locally that is 0.113". With the grease seals, it's going to be a very tight fit. I should probably try to order thinner washers. I bet this thing was never right.Something to consider when you put it all back together Marty. The newer frames seem to have a bit more clearance across the mount bosses than the earlier frames.

Well, look at it this way... let's say it took 20ft-lbs of torque to close that gap (actually, it's probably quiet a bit more for that much gap)... anyway, say it was torqued to 30ft-lbs. Only 10ft-lbs of that went to clamping the pivot tube... the other 20lbs went into just sucking the frame in enough to touch the tube.

If it were me, I'd rather too tight than too loose.With the grease seals, it's going to be a very tight fit. I should probably try to order thinner washers.

That's how I feel about it as well.If it were me, I'd rather too tight than too loose.

That's exactly what I'm thinking! Two 1 mm thick washers would about do it. Otherwise, using what I have goes on the right side.So, which side do you put the shim on? Not the sprocket side I assume? 1/8" is about 3mm. That could really throw the sprocket alignment off.

Similar threads

- Replies

- 97

- Views

- 22K

- Replies

- 785

- Views

- 82K

- Replies

- 11

- Views

- 1K