I posted in this thread a while ago about the steel plates I got to use as a top for a smallish welding/fixture table. Well I finally got around to making a stand so I thought I'd show you guys what I've been up to.

The top is only about 32" x 42", but 1-1/4" thick so it weighs about 525lbs. They were used as machine bases and are flat to within a few thousands.

They were used as machine bases and are flat to within a few thousands.

Here's a picture with the temporary stand I made for the two top pieces when I first got them.

I flipped the plates upside down and built the new base for the table using 2" square tubing. It took a lot more work to get this far than I thought it would! I'm somewhat of a perfectionist so that didn't help!

It has 3/8" plates that the corners of each top piece bolt to. Each piece can be individually leveled using set screws. The stand also has swivel leveling feet to level the whole thing. The top has a 2.5" overhang all the way around to make it easier to clamp things to it.

Here are a couple of shots of it pretty much done. I just need to add a shelf on the bottom and actually level the top pieces on the base. I might also add a few tool holders.

My 5" Wilton (Snap-on branded) Vise! Great Craigslist score!

Putting the table to use:

The top is only about 32" x 42", but 1-1/4" thick so it weighs about 525lbs.

Here's a picture with the temporary stand I made for the two top pieces when I first got them.

I flipped the plates upside down and built the new base for the table using 2" square tubing. It took a lot more work to get this far than I thought it would! I'm somewhat of a perfectionist so that didn't help!

It has 3/8" plates that the corners of each top piece bolt to. Each piece can be individually leveled using set screws. The stand also has swivel leveling feet to level the whole thing. The top has a 2.5" overhang all the way around to make it easier to clamp things to it.

Here are a couple of shots of it pretty much done. I just need to add a shelf on the bottom and actually level the top pieces on the base. I might also add a few tool holders.

My 5" Wilton (Snap-on branded) Vise! Great Craigslist score!

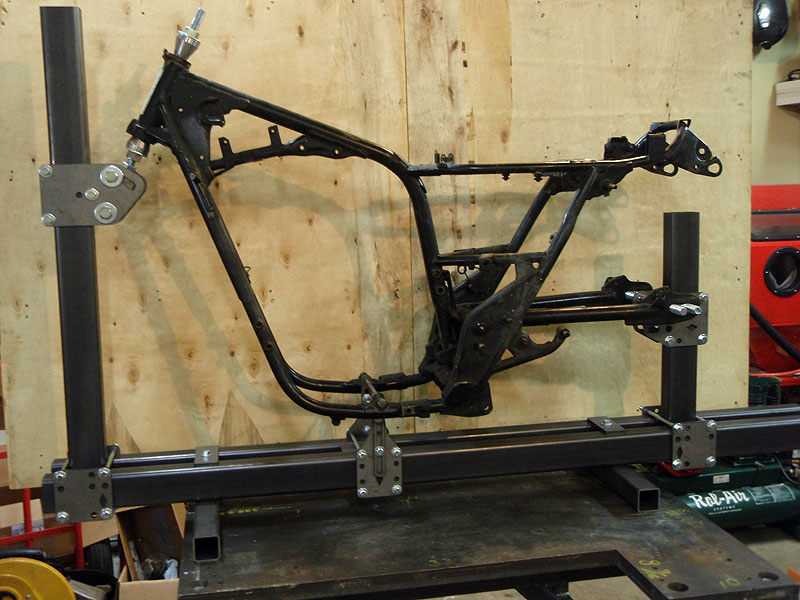

Putting the table to use:

Here's the thread in the shops section:

Here's the thread in the shops section: