My first job was as a factory labourer, but during my lunch hours taught myself to weld and ended up on the bench. Mostly furniture, balustrading, shop fittings and so on, oxy and stick. I worked at this for five years, then off and on for the next five years before joining the RAAF. I ended up a damn good welder, could weld pretty well anything but never tried aluminium until a couple of years ago. Sadly lack of practice and health problems have seen my skills deteriorate, I very rarely weld now, just the odd job here and there, but I can still stick weld 1.5mm thick steel. The trade has changed a lot since I left it 50 years ago, back then mig and tig were unheard of, everything was welded with oxy or stick.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding thread

- Thread starter G_YamTech_314

- Start date

Made a new tail for my WP17 out of a pen blank.

Nice custom back cap!

Some food grade weld porn with my Wledtech WP17F fitted with a CK PYREX 18 cup and gas lens. If you’re wondering how much gas I use with that monster cup, the answer is all of it with back flushing as well.

TJZ662

XS650 Addict

18? Woah lol that’s alot of gas. Nothing beats back up gas, I do love using heat sinks as well to avoid distortion. I pretty much always use a 10 or 12 furrick cup, unless a crazy long stick out is needed

OSome food grade weld porn with my Wledtech WP17F fitted with a CK PYREX 18 cup and gas lens. If you’re wondering how much gas I use with that monster cup, the answer is all of it with back flushing as well.

View attachment 221515View attachment 221516View attachment 221517View attachment 221518

I've been wanting to try the Furrick cups and lenses but haven't been able to talk myself into forking over the $$ for yet. I have a whole pile .5" thick aluminum chunks of various shape for sinks. I think you can see the corner of my big one poking out from under the stainless plate there.18? Woah lol that’s alot of gas. Nothing beats back up gas, I do love using heat sinks as well to avoid distortion. I pretty much always use a 10 or 12 furrick cup, unless a crazy long stick out is needed

TJZ662

XS650 Addict

I get them off of weldmonger.com they come with Ck lenses. I don’t think you can get better ones. Not really sure. Those Pyrex cups though sure brightening everything up!

I actually had some issues with the pyrex cups filtering out certain waves of UV and my lens turning off if I didn't have enough stick out. I had to adjust the sensitivity of of my hood as well. I only had the issues with the 2X4 auto lens in my Huntsman hood but not my Jackson EQC hood.I get them off of weldmonger.com they come with Ck lenses. I don’t think you can get better ones. Not really sure. Those Pyrex cups though sure brightening everything up!

TJZ662

XS650 Addict

Honestly I couldn’t tell the difference between similarly priced auto lenses. I have a Jackson insight which is pretty standard quality. It wasn’t until I tried a friend’s Lincoln Viking and a speed glass that I realized how crappy most standard priced auto lenses are. I still use a fixed lens out in the field but man oh man would I like to spurge and get a quality lid

My Jackson EQC was a pretty pricey hood at the time (12 years ago) I dont even think they make that one any more. But it has been one helluva sweet hood. My Huntsman has a viking insert in it, its ok.... I have an ancient fibremetal pipeliner 2x4 flip front (bottom chopped) with passive glass that I use for stick and outdoor welding. I think its probably older than I am, I stole it from my dad in the 90's and it was old then. Most likely from the late 60's or early 70's. I've replaced the headgear in it 2 twice but its a battle hardened war hood. I got my ass chewed by a union fitter on a job site once because it had a Pipefitters local 533 sticker on it, and I wernt in it (dad was). I promptly peeled it off.Honestly I couldn’t tell the difference between similarly priced auto lenses. I have a Jackson insight which is pretty standard quality. It wasn’t until I tried a friend’s Lincoln Viking and a speed glass that I realized how crappy most standard priced auto lenses are. I still use a fixed lens out in the field but man oh man would I like to spurge and get a quality lid

As a newb welder (with iffy vision too), I started with an Eastwood labelled auto-darkening helmet. Welded a bit with bi-focals under the lid, changed to a cheater set-up - still couldn't get clarity on the pool desired. About a year ago, I decided to get a Viking 3350 - boom!

The difference was amazing - literally night and day - and with 2.0 cheaters, I can actually see what I'm doing

The difference was amazing - literally night and day - and with 2.0 cheaters, I can actually see what I'm doing

Yeah the 3350 is great hood, we have one at the shop for communal use. I tried cheaters once and felt like it threw off my depth perception, but ive got perfect vision so I'm not sure they were really needed.As a newb welder (with iffy vision too), I started with an Eastwood labelled auto-darkening helmet. Welded a bit with bi-focals under the lid, changed to a cheater set-up - still couldn't get clarity on the pool desired. About a year ago, I decided to get a Viking 3350 - boom!

The difference was amazing - literally night and day - and with 2.0 cheaters, I can actually see what I'm doing

Last edited:

Interesting to hear about depth perception - I have a cheap motorcycle helmet and if I use the built in sun visor my distance/speed perception goes to pot. Must be something about the optical clarity of the visors, welding and motorcycle.

TJZ662

XS650 Addict

Well yeah man. If you can’t see you can’t see

I was using the exact same Pyrex for the last few days while doing some carbon pipe...then I rolled the pipe and watched in horror as the torch fell to the floor...it was all in slow motion!!!Some food grade weld porn with my Wledtech WP17F fitted with a CK PYREX 18 cup and gas lens. If you’re wondering how much gas I use with that monster cup, the answer is all of it with back flushing as well.

View attachment 221515View attachment 221516View attachment 221517View attachment 221518

Those are a little pricey, I got one of those magnetic torch holders for the work bench. That's an awful big cup to walkI was using the exact same Pyrex for the last few days while doing some carbon pipe...then I rolled the pipe and watched in horror as the torch fell to the floor...it was all in slow motion!!!

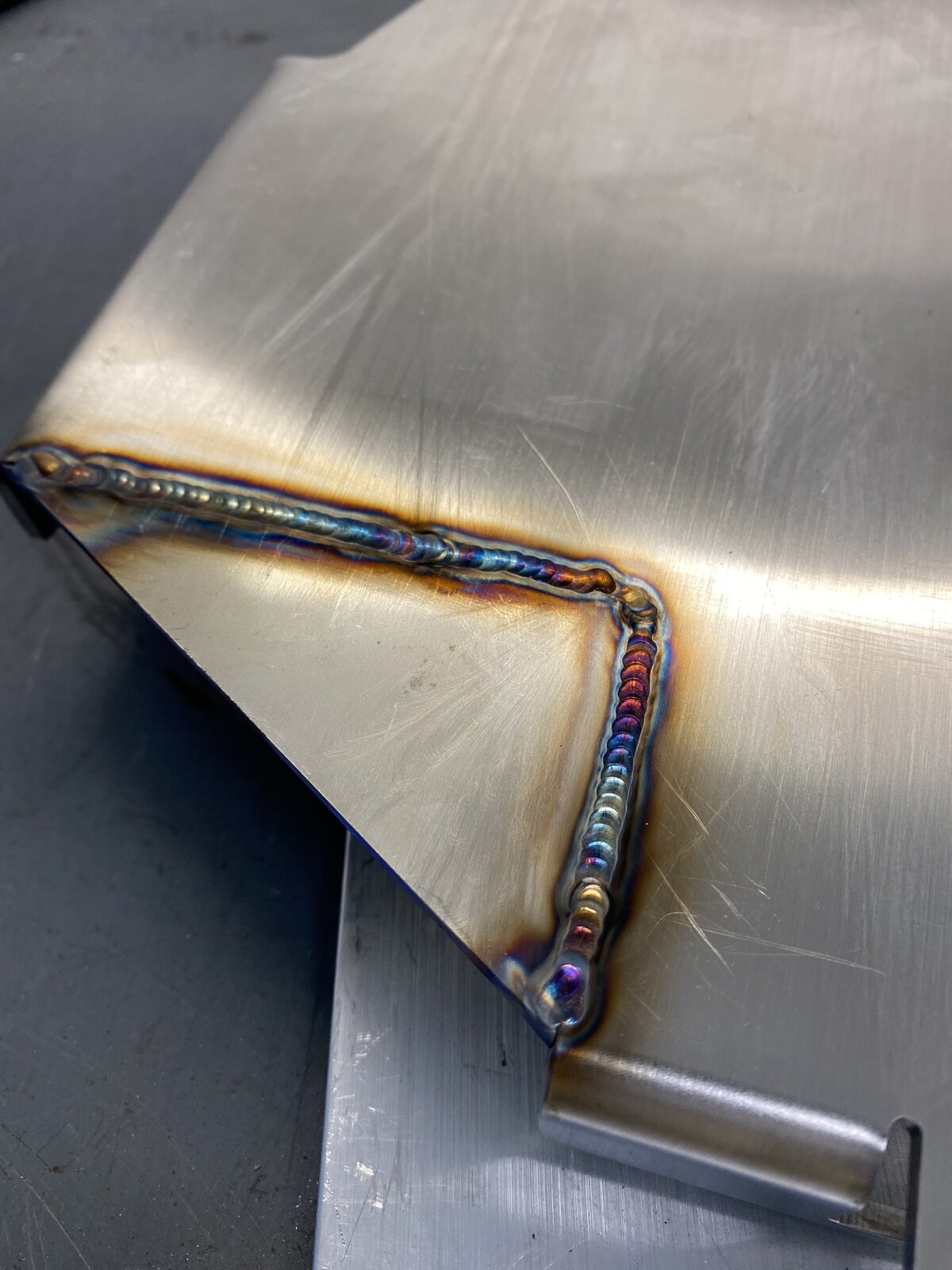

After finally getting my stick welding cert, I got to move on to TIG! My first class I spent the entirety just figuring out how to move the cup (I need to move my whole body to find the groove lol). Today I got to try adding filler rod. It was my first time ever doing this, and I didn’t do great, but it was an absolute blast. A true art form and I look forward to progressing and learning more!

A skill that will always be in high demand. Good luck.It's honestly a quite enjoyable field, however, my bosses are dicks and I don't get the opportunity to weld frequently. When I do it's only 10% of my day, and takes seconds. They like to rush the process and it's stressful. Thinking of going back to school and developing my future to be more than a laborer. Idk... The road is long, but I'm moving fast down that road, so who knows where it will take me. It's never a bad skill to have, that's for sure.

After finally getting my stick welding cert, I got to move on to TIG! My first class I spent the entirety just figuring out how to move the cup (I need to move my whole body to find the groove lol). Today I got to try adding filler rod. It was my first time ever doing this, and I didn’t do great, but it was an absolute blast. A true art form and I look forward to progressing and learning more!

View attachment 228033

Looking good Jessee! I know you are a pipe fitter, at one time in my life , I was the guy who used to follow the pipe fitters around and burn rod for 8 hours a day. I never came out from under my hood and leathers. I always envied guys who welded aluminum for a living. Such nice clean work and no chipping slag!

Similar threads

- Replies

- 53

- Views

- 2K