Those are very durable machines. Have you visited XJBikes.com. Support (including parts) there is extremely good.FINALLY have the valves set and started it up last night. Sounded good but I just idled for about half a minute.

Will swap the tensioner parts this weekend (monday off!)

Hope to get a test ride in now that rear tire is also new.

also plan to vinyl wrap the tank just to see how it will look when painted.

Busy weekend cause I just picked up another project bike. 82 XJ650. I already have an 83 XJ650 ( you can see the red one in the background of the pic)

I reworked the 83 last year so this will be familiar. I got it so cheap and with spare carbs, original seat, original fender, riding gear, 2 helmets I could not say no. Bike is hacked up some with different seat, turn signals, tail light and bars (cables are a bit of a mess) Besides his wife was about to give birth and wanted it out of the garage

View attachment 259532

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1978 XS650 Special Project

- Thread starter Melnic

- Start date

Oh yes, That's where I got tons of advice on the 83Maxim last year ThxThose are very durable machines. Have you visited XJBikes.com. Support (including parts) there is extremely good.

My 83 Maxim is VERY SMOOTH running. Syncing carbs on that YICS motor even using the tool I got is more involved. Gotta pull the tan, use the YICS blocking tool.

XS650 is much easier.

I like the sound of a twin better though.

Waiting for weather to clear up I have been test painting some metal plates with different colors and testing my painting methods.

I vinyl wrapped the tank today with my son helping me hold the vinyl sheets. This looks worse up close w/ wrinkles and it only temporary till I do the painting in warmer weather but it gives me a good idea on how I want the paint to go. I will also put the sideways U pattern on the side panels.

One thing is the tank emblem. To use the big YAMAHA emblem from '78 or one that is more like the 1971 XS650 which this paint scheme is copied from.

I vinyl wrapped the tank today with my son helping me hold the vinyl sheets. This looks worse up close w/ wrinkles and it only temporary till I do the painting in warmer weather but it gives me a good idea on how I want the paint to go. I will also put the sideways U pattern on the side panels.

One thing is the tank emblem. To use the big YAMAHA emblem from '78 or one that is more like the 1971 XS650 which this paint scheme is copied from.

You just mock it up and post pictures. We will TELL you which way to go.Waiting for weather to clear up I have been test painting some metal plates with different colors and testing my painting methods.

I vinyl wrapped the tank today with my son helping me hold the vinyl sheets. This looks worse up close w/ wrinkles and it only temporary till I do the painting in warmer weather but it gives me a good idea on how I want the paint to go. I will also put the sideways U pattern on the side panels.

One thing is the tank emblem. To use the big YAMAHA emblem from '78 or one that is more like the 1971 XS650 which this paint scheme is copied from.

View attachment 260161

That’s a nice looking Special!

Roads dry enough to ride in the neigborhood.

Took both those bikes out today and its 40F outside.

Both bikes running lean enough to bog some. The XJ stopped bogging when I turned on some of the fuel enrichment, The XS the FE is not so easy to just give "a little" Feels like mid range is lean at this cold temperature. Debating on if I'll touch the jets/needle or just wait for warmer weather.

Had a duh moment w/ the 83 XJ650 as while warming up it died on me. Would start w/ some carb start sprayed into the back of the filter, then checked bowl levels (its easy on that bike w/ the drains). Bowls half full....... Hmm, duh, forgot to turn on the manual petcock LOL Started right up after I turned it to RES then let the bowls fill back up.

LOL Started right up after I turned it to RES then let the bowls fill back up.

Took both those bikes out today and its 40F outside.

Both bikes running lean enough to bog some. The XJ stopped bogging when I turned on some of the fuel enrichment, The XS the FE is not so easy to just give "a little" Feels like mid range is lean at this cold temperature. Debating on if I'll touch the jets/needle or just wait for warmer weather.

Had a duh moment w/ the 83 XJ650 as while warming up it died on me. Would start w/ some carb start sprayed into the back of the filter, then checked bowl levels (its easy on that bike w/ the drains). Bowls half full....... Hmm, duh, forgot to turn on the manual petcock

So its a warm 70F and took the bike into the neighborhood. For the first 10 minutes I feel it was very lean. I warmed up the bike about 3 minutes before riding. It was hesitating and popping. I used a colortune and I turned it from blue to yellow and stopped there (that is the border of Rich).

I have stock Jetting and am currently running Uni Filters with the black on the inside and red on the outside. I oil/gas soaked/squeezed the black filter.

Suggestions?

I have stock Jetting and am currently running Uni Filters with the black on the inside and red on the outside. I oil/gas soaked/squeezed the black filter.

Suggestions?

78/79 BS38’s fitted with Uni Pods and using the stock exhaust system would benefit with a one size up on both main jets and pilot jets.

Possibly even two up on the mains.

Possibly even two up on the mains.

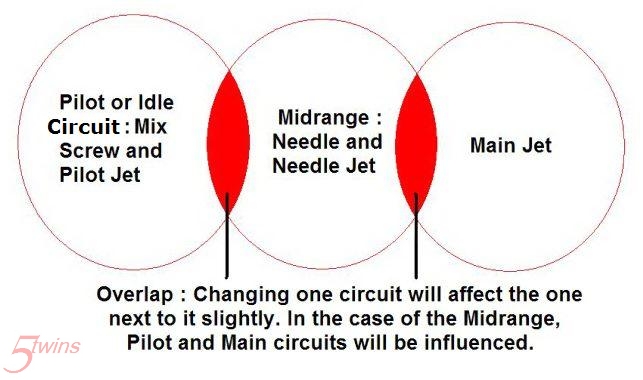

If you increase the main jet size at all, even one size, on the '78-'79 carb set, you're going to have to lean the needles a step as well. The upper midrange is borderline too rich to begin with from the factory. Any main jet size increase pushes it over the edge and will result in break-up if pushed hard. But when you lean the needle, it also leans the idle to lower midrange transmission area and can create a flat spot there, hence the need to increase the pilot jets a size as well. The stock pilots are usually OK if the needle isn't leaned a step, but as I said you usually can't increase the mains without needing to lean the needles a step too. The 3 circuits in your carb overlap a bit. If you change one, it affects the area of the one next to it that is right next to it. Changing the main also affects the upper midrange, changing the pilot also affects the lower midrange. Changing the needle clip position affects both the lower portion of the main and the upper portion of the idle circuit .....

Here is a pic example of moving that clip up the needle to the 2nd position which in effect lowers the needle leaning the mixture.

so, I think its lean at between 1/8-1/4 throttle as Im accelrating. Would that not be a pilot/needle thing?

My idle is rich already so does that not point to the needle? I think I should pull the tops off the carbs and then look at where the needle clips are right now. What is the stock position of the needles in a 78?

My idle is rich already so does that not point to the needle? I think I should pull the tops off the carbs and then look at where the needle clips are right now. What is the stock position of the needles in a 78?

In the middle, or the #3 slot (from the top) .....

While it's apart, check the needle to make sure it's the right one (5O2). The way these bikes get changed around, there's no telling what's in there. Also make sure to assemble it correctly with the washers and spacer ring in the right spots or the needle won't sit at the proper height. XSE 2Timer's photo shows the correct assembly sequence (spring, metal washer, e-clip, and finally the thick plastic spacer ring on top).

While it's apart, check the needle to make sure it's the right one (5O2). The way these bikes get changed around, there's no telling what's in there. Also make sure to assemble it correctly with the washers and spacer ring in the right spots or the needle won't sit at the proper height. XSE 2Timer's photo shows the correct assembly sequence (spring, metal washer, e-clip, and finally the thick plastic spacer ring on top).

Does this guide have a number cast into it? I’m just comparing it to the one supplied by XS650Direct which has A0147 or L0147 cast into the aluminum between the bolt lugs.Looks like things are unchanged.

Thread depth is about 8-10mm

Removed the top mount, coils, condenser and neutral switch

I"m cleaning all the bullet connectors as I pull them off cause I know I won't be wanting to do that as I'm putting things back together.

Tomorrow I'll be loosening the rear wheel and pull the chain off.

Unless there are interruptions, should have it pulled and onto the stand this weekend.

Primary coils were 4.3ohms

Orange wire to caps were 13.3K on both (I have NGK resistive caps installed)

Parts from each section are going in zip lock bags. then into a cardboard box.

If fasteners can be put back on the bike (like the ones holding the foot peg brackets) I do so. Otherwise they get re assembled onto their part and put in the bag.

Idea for me is that when I"m done putting it back together, all bags should be empty.

View attachment 256417View attachment 256418

Found a pic I took back before I put it inDoes this guide have a number cast into it? I’m just comparing it to the one supplied by XS650Direct which has A0147 or L0147 cast into the aluminum between the bolt lugs.

A0147 is on the Mikesxs that I put in.

K thx. This is from the XS650DIRECT website. Looks like the same casting. Holes look crooked, probably to get bolts perpendicular to the mounting face.Found a pic I took back before I put it in

A0147 is on the Mikesxs that I put in.

AgainK thx. This is from the XS650DIRECT website. Looks like the same casting. Holes look crooked, probably to get bolts perpendicular to the mounting face.

View attachment 260585

The machining matches the angle of the flat face as what is needed. The round cylinder shape in the casting should have been made to follow that angle but they did not. There is enough metal to angle the threaded holes but it makes it look off

They've (somewhat) fixed 'em then. The ones Mikes was selling... the ones that caused me to make my own.... weren't. They were both cast AND machined wrong. The holes were way off of square.Again

The machining matches the angle of the flat face as what is needed. The round cylinder shape in the casting should have been made to follow that angle but they did not. There is enough metal to angle the threaded holes but it makes it look off

Mikes guide in back.

That was a very bad product they were selling back then.They've (somewhat) fixed 'em then. The ones Mikes was selling... the ones that caused me to make my own.... weren't. They were both cast AND machined wrong. The holes were way off of square.

Mikes guide in back.

View attachment 260613

Following, studying and thankful for the pics and information regarding the chain guides.

Also thankful that this guide concluded to be a decent original XS front guard is to good have.