Just about ready to test ride.

I"m really happy about how the Timing turned out. I think it was 5Twins? that said to target the right F mark?

After the static timing, the dwell was where suggested at 22.5

I only had to move the rotation of the disk to get the right side to the right hash mark, the left was spot on w/o doing anything.

Engine is idling excellent. I adjusted the idle mixture a tad leaner doing it by ear. I could stand to use my colortune though I feel that is best done when the weather is warmer.

I need to block off a couple hours for a test ride in case I want to address an issue.

Today I tightened up a loose engine mounting bolt

Adjusted Timing

adjusted idle mixture

Sync'd carbs (only needed 1/16 of a turn)

Put the points and Alternator cover plates back on

I'm really happy where the timing came out on the adjustment. With that stretched chain, the timing was all the way CW to get the timing right w/ a wide points gap. Now I'm smake dab in the middle of the adjustments for the timing and on the wide side of the spec for the points gap/dwell but still looking good.

I have to believe that now I have the timing chain replaced, the valves timing are where they should be for the crankshaft timing. That has to make an improvement. Test ride will see.

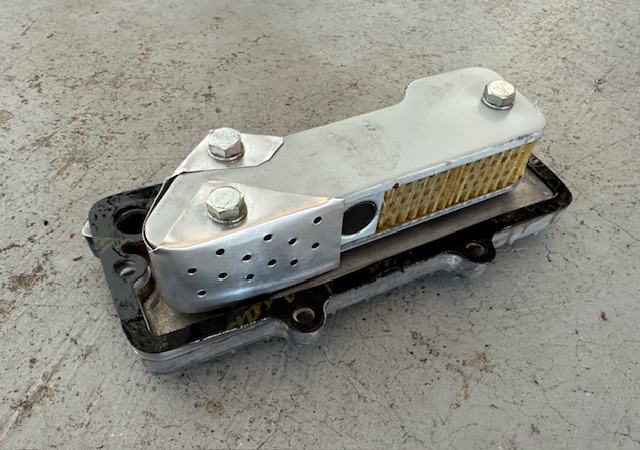

Oh, and I did something a little experimental today if anyone can spot it?