Oh, and I also put on a new RK 530 Chain/new sprockets (front/rear) same stock ratio for now.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'79 Special Cafe Build Project Begins (20 years late?)

Up next, new steel brake line, new high performance front brake rotor, which just arrived, and will address my leaking petcocks while the tank is out to paint.

Quick question, so I have noticed a very slow weep/leak coming from the front caliper (at the threads on the bleeder valve)... this started after I bled the brakes a while back. Initially I thought perhaps it was brake fluid that was excess on the threads, so I kept a little towel there, but after a few weeks, it still is leaking a drop or so a day. It doesn't seem to be hindering the caliper's operation, or the feel on the brake lever, so not likely bringing air back in...but I'd like to stop the leak. I have it down pretty tight, but that metal feels really soft and I don't want to over tighten the valve... perhaps I already did and that's causing the leak?

Is there a torque value I should stick with (I didn't see one mentioned in my manual) or should I just crank it down further? What are other ways to address this? I don't think having teflon tape on there is a good idea...thoughts?

Thanks!

Quick question, so I have noticed a very slow weep/leak coming from the front caliper (at the threads on the bleeder valve)... this started after I bled the brakes a while back. Initially I thought perhaps it was brake fluid that was excess on the threads, so I kept a little towel there, but after a few weeks, it still is leaking a drop or so a day. It doesn't seem to be hindering the caliper's operation, or the feel on the brake lever, so not likely bringing air back in...but I'd like to stop the leak. I have it down pretty tight, but that metal feels really soft and I don't want to over tighten the valve... perhaps I already did and that's causing the leak?

Is there a torque value I should stick with (I didn't see one mentioned in my manual) or should I just crank it down further? What are other ways to address this? I don't think having teflon tape on there is a good idea...thoughts?

Thanks!

scabber

XS650 Guru

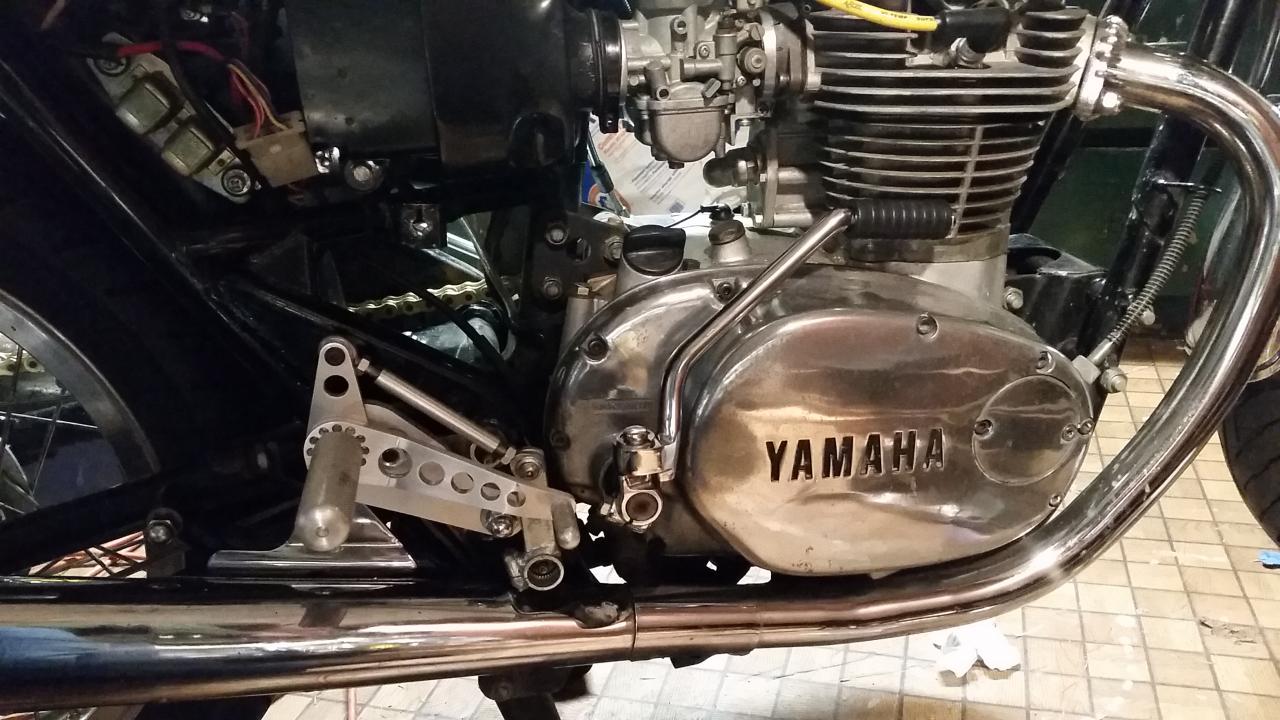

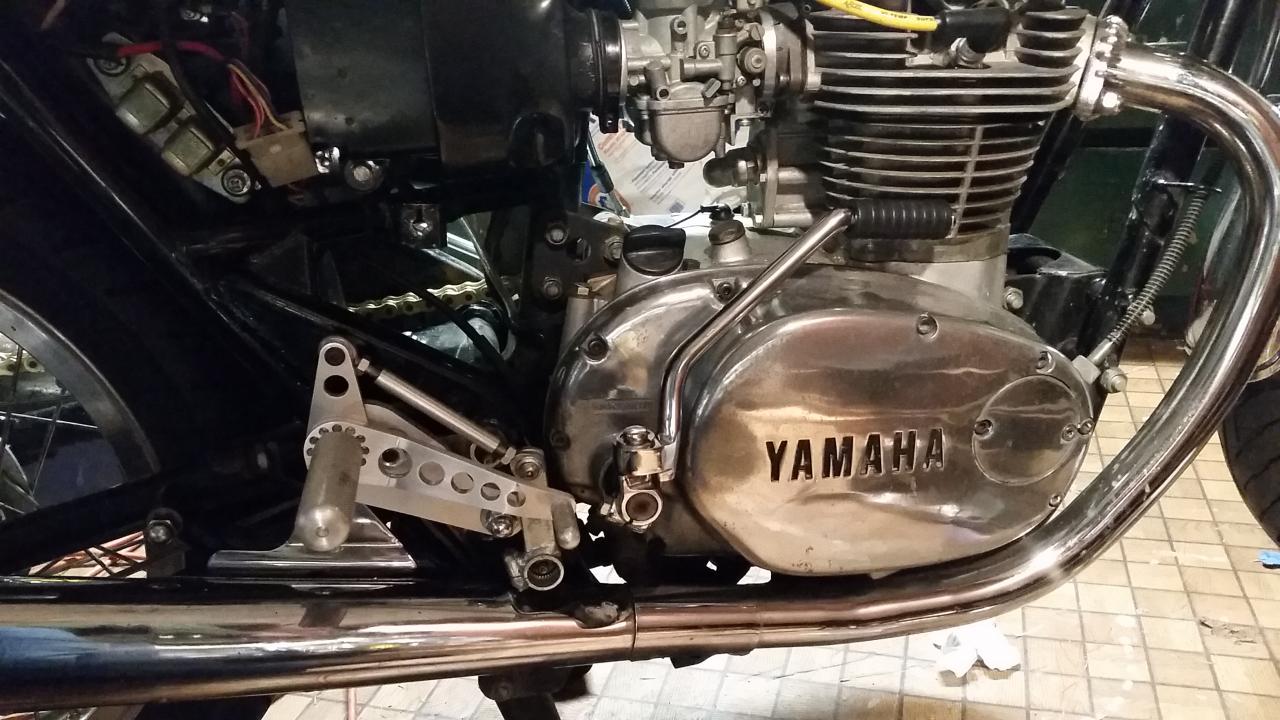

Looks like you have been busy. The new seat and rear sets look good. Now all we need is some better weather.

Looks like you have been busy. The new seat and rear sets look good. Now all we need is some better weather.

Seriously...would love to get some dry days around here...although I can't do much until I get my parts back from paint...so on second thought, the weather can do what it wants for now.

Couldn't wait to get the new front brake rotor on and brake line...having a free morning, I took advantage of it and got it done.

The new rotor is so much lighter, and was a simple install. Cleaned up the caliper, and added the shims that were supplied with it...also connected the new steel brake line, bled the MC and also addressed the leaking bleeder valve...simply cleaned up the base, and no leaks!

All works great...but can't really tell how it all feels until I can ride this thing!

More to come.

The new rotor is so much lighter, and was a simple install. Cleaned up the caliper, and added the shims that were supplied with it...also connected the new steel brake line, bled the MC and also addressed the leaking bleeder valve...simply cleaned up the base, and no leaks!

All works great...but can't really tell how it all feels until I can ride this thing!

More to come.

pereiracycles

XS650 Enthusiast

Is that the XS Performance rotor? How thick is it?

Is that the XS Performance rotor? How thick is it?

Yes, it is. It is significantly lighter, I think half the weight of stock, and is 3.5mm thick vs. 7mm of the stock rotor.

pereiracycles

XS650 Enthusiast

Yes, it is. It is significantly lighter, I think half the weight of stock, and is 3.5mm thick vs. 7mm of the stock rotor.

Good to know. I swapped my fork for one from an R6 and the blue dot caliper lands right over the stock rotor, but that rotor is too thick. Was hoping to find something used, but am not having luck so this might be the way to go. Can you tell me the offset of the rotor?

Thanks!

I don't know the offset off hand, but the rotor is not nearly as offset as the stock rotor. It came with spacers for the brake caliper to shift over, approx. 6mm. So if your caliper lands right on the stock location of the stock rotor, then with performance rotor, it too would need the spacers (supplied), and the width sounds like it would work.

pereiracycles

XS650 Enthusiast

Shoot, that would put my caliper into the spokes. Back to the drawing board. Good luck with your project. It is looking good. Thanks again.

Not sure if it's viable, but you could look into putting a spacer on the rotor itself?

Time for an update...I'm still waiting on paint, so not much to do but wait, wait, wait. However, I have taken the time to address a few issues I can:

With the rearsets in, one of the issues that most are familiar with is that the stock kicker won't clear them without doing some modification. I was leaning towards the heat/bend idea, but saw some bikes have used the RD400 bent kicker instead. I checked out ebay, and lost to another bidder, and then found a new/repro kicker on Yambits... ordered, and arrived this week! The fit is great, although there was a little slop in the play, which I fixed with a thicker washer (If people want pics of this, I can supply).

At anyrate, the kicker fits well, and clears the foot peg perfectly. It doesn't however clear the brake pedal. (I knew that was going to be a problem when I ordered it) Reading up on possible solutions, many people drill out the position holes on the rearset assembly so that the brake pedal can rotate up, but still engages the brake once set back down... I was debating this idea, but hate to drill out the new rearsets...what to do?

So instead, I decided that really, all that is needed is a quick disconnect of the brake assembly (extension bar) and that should solve my issue. So I took the bolt connecting the rod to the rearset and drilled a hole for a hitch pin clip.

Here it is mounted on the bike:

Since the bolt takes the force when pressing on the lever, I don't think the hitch pin will be an issue for strength... and the brake lever functions as designed. If I need to use the kicker (Using electric starter primarily for now), then I simply pull the pin, rotate the brake pedal, and use the RD400 kicker like this:

then reconnect the brake pedal--takes less than 5 seconds to put back...and I'm off. It's not a perfect solution, but not bad. We'll see how it holds up over time.

I've also spent the better part of last weekend cleaning/refurbishing my leaking vaccum petcocks from my XS750 tank. I got a rebuild kit, tore apart the petcocks, cleaned, buffed and reassembled it...hopefully they'll work much better now... the gaskets were all hard, and the O-rings on the diaphrams weren't sitting well--which I am assuming was the primary reason they leaked. I won't really be able to tell if they are cured until I get the tank back, but I'm optimistic.

I did notice that one of the petcocks had a broken screen on it's filter...looking online, I am seeing prices of $45+ for just one, WTF!?? So I went to a salvage yard, and happened to find one, SCORE! $5 bucks later, and I'm a happy camper.

And now more waiting.

With the rearsets in, one of the issues that most are familiar with is that the stock kicker won't clear them without doing some modification. I was leaning towards the heat/bend idea, but saw some bikes have used the RD400 bent kicker instead. I checked out ebay, and lost to another bidder, and then found a new/repro kicker on Yambits... ordered, and arrived this week! The fit is great, although there was a little slop in the play, which I fixed with a thicker washer (If people want pics of this, I can supply).

At anyrate, the kicker fits well, and clears the foot peg perfectly. It doesn't however clear the brake pedal. (I knew that was going to be a problem when I ordered it) Reading up on possible solutions, many people drill out the position holes on the rearset assembly so that the brake pedal can rotate up, but still engages the brake once set back down... I was debating this idea, but hate to drill out the new rearsets...what to do?

So instead, I decided that really, all that is needed is a quick disconnect of the brake assembly (extension bar) and that should solve my issue. So I took the bolt connecting the rod to the rearset and drilled a hole for a hitch pin clip.

Here it is mounted on the bike:

Since the bolt takes the force when pressing on the lever, I don't think the hitch pin will be an issue for strength... and the brake lever functions as designed. If I need to use the kicker (Using electric starter primarily for now), then I simply pull the pin, rotate the brake pedal, and use the RD400 kicker like this:

then reconnect the brake pedal--takes less than 5 seconds to put back...and I'm off. It's not a perfect solution, but not bad. We'll see how it holds up over time.

I've also spent the better part of last weekend cleaning/refurbishing my leaking vaccum petcocks from my XS750 tank. I got a rebuild kit, tore apart the petcocks, cleaned, buffed and reassembled it...hopefully they'll work much better now... the gaskets were all hard, and the O-rings on the diaphrams weren't sitting well--which I am assuming was the primary reason they leaked. I won't really be able to tell if they are cured until I get the tank back, but I'm optimistic.

I did notice that one of the petcocks had a broken screen on it's filter...looking online, I am seeing prices of $45+ for just one, WTF!?? So I went to a salvage yard, and happened to find one, SCORE! $5 bucks later, and I'm a happy camper.

And now more waiting.

- - - then reconnect the brake pedal--takes less than 5 seconds to put back...and I'm off. It's not a perfect solution, but not bad. We'll see how it holds up over time. - - -

Hi Brassneck,

most likely that'd be 5 seconds plus however long it takes to pick up those fiddly little parts after you dropped them in the street?

What I'd do would be to put a 90º hinge-up end on the brake pedal so it'd click up out of the way when you kicked and you could flip it down again with your boot toe when the engine starts.

That's a great idea...do you happen to have a source for the hardware?

That's a great idea...do you happen to have a source for the hardware?

Hi Brassneck,

alas, no.

Me, I would look at how a fold-down footpeg worked and carve myself a miniature version out of bar stock.

You may get lucky trolling the net to find one.

Hi Brassneck,

alas, no.

Me, I would look at how a fold-down footpeg worked and carve myself a miniature version out of bar stock.

You may get lucky trolling the net to find one.

Ya, I took a look around but didn't see anything. The concept is perfectly simple, and there's plenty of examples for the foot peg, but of course that's not an issue. I think if I were to fabricate something, the mechanism would itself be as big as the pedal itself, and with the limited room I have with the kicker, likely defeats the point...if it were low profile, that would be ideal.

Well, good idea, but I'll stick with this until I find a better plan.

Thanks for the comment nonetheless.

Been a while since I updated...and not a whole lot to tell. I've been patiently waiting for the tank/seat to come back from paint....and just got word, I get them back tomorrow! Feels like Christmas Eve...very excited!

Meantime, I suppose I haven't been too idle. I've been cleaning up all the grounds, cleaning up connections and getting things more "tidy".

Oh, and I've played a little with some pin-striping tape on the headlight... not sure I'll keep it as it depends if it works with the new paint job on the tank/seat. Will know more tomorrow!

Meantime, I suppose I haven't been too idle. I've been cleaning up all the grounds, cleaning up connections and getting things more "tidy".

Oh, and I've played a little with some pin-striping tape on the headlight... not sure I'll keep it as it depends if it works with the new paint job on the tank/seat. Will know more tomorrow!

angus67

Welder's penetrate deeper!!

looks fantastic. considered a fork brace? Perhaps a upgrade in head bearings?

may also consider a voltmeter to keep tabs on the charging. When the charging goes dead, you have very little time to get to were your going.

Personally, I would keep the clubmans. I think clip-ons look too modern on these bikes.

may also consider a voltmeter to keep tabs on the charging. When the charging goes dead, you have very little time to get to were your going.

Personally, I would keep the clubmans. I think clip-ons look too modern on these bikes.

Thanks Angus,

I appreciate the feedback. I am growing to like the clubmans And may just stay with them. and funny you mention a voltmeter...picked one up off eBay last week...the hard part is figuring out where to mount it discretely. It's a small LED unit...so I'll be playing around with conspicuous locations.

I appreciate the feedback. I am growing to like the clubmans And may just stay with them. and funny you mention a voltmeter...picked one up off eBay last week...the hard part is figuring out where to mount it discretely. It's a small LED unit...so I'll be playing around with conspicuous locations.

Brassneck...you my friend, are doing some fantastic work!

I really like the quality and tastefulness of what you've done (especially as opposed to some of the other hack jobs...sheesh!).

At any rate, I see you're in Seattle, I'm in Olympia and am a pretty hardcore XS-650 lover myself.

Perhaps we could swap parts, contacts, lies, etc...some time?

Drop me a note sometime if you'd like.

Vincent

I really like the quality and tastefulness of what you've done (especially as opposed to some of the other hack jobs...sheesh!).

At any rate, I see you're in Seattle, I'm in Olympia and am a pretty hardcore XS-650 lover myself.

Perhaps we could swap parts, contacts, lies, etc...some time?

Drop me a note sometime if you'd like.

Vincent