Meddy

XS650 Addict

Please don't tell me thats your hand holding that spider

No, I'm not that brave Peanut, In fact I think your braver, you have openly declared your phobea, I won't.

And yes, there will be a video when the bikes finished

Please don't tell me thats your hand holding that spider

I'm wondering if that washer "splayed" your fork lowers out a tad. That could give excessive stiction (friction) in the forks.....I'm not sure if I'm totally happy with this solution

This was my initial concern Jim, but the washer slipped in nicely without having to wedge it in.I'm wondering if that washer "splayed" your fork lowers out a tad. That could give excessive stiction (friction) in the forks.....

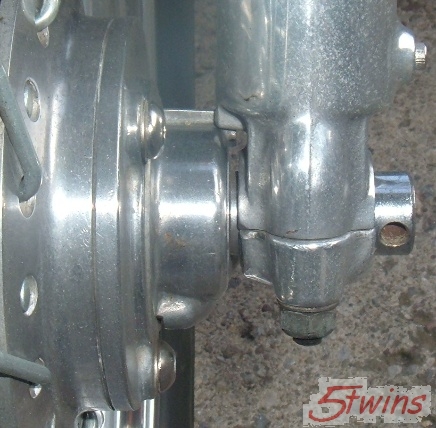

The stepped end of your axle is supposed to accomplish the proper spacing for you.

Keep in mind here our axle's sittin' on the bench.... If your wheel stack plus the extra washer fit between the lowers without interference Mick, you're golden. I'd say it's a good fix. If on the other hand, you had to spread 'em... you're gonna need a plan B.

Thanks for the pic 5T, I completely understand the concept, and what is supposed to happen and mine pretty much looks like the one in your pic including the small gap between the speedo drive and the inside of the bottom clamp, but when I tighten up the axle nut with the bottom clamp only finger tight so I can spin the axle in it the left side rotor contacts the caliper mount and locks it solid.Here's what mine looks like. The stepped part of the axle gets pulled through the leg and acts as the spacer, no added washer required .....

As 5T points out, that shouldn't happen Mick. Theoretically you could put a speedo drive in there say a quarter of an inch thinner, and the axle should just suck in to compensate for that. It shouldn't pull the lower with it. Sounds like, as 5t says, the lower is catching on the axle and being pulled in for some reason. A rather large burr on the axle maybe? But if using the washer works....is that the speedo drive housing on mine has somehow worn down where the boss contacts the recess in the lower fork leg allowing the fork leg to be pulled inboard when tightening the axle

Theoretically you could put a speedo drive in there say a quarter of an inch thinner, and the axle should just suck in to compensate for that. It shouldn't pull the lower with it.

If worse comes to worse, I guess you're going to just have to use the spacer washer, but you really shouldn't need one there. The assembly is designed to work without one.

Brace came with the bike, a period hotrod, haven't seen another quite like it.Thanks for the video Gary, I tried out your technique and both tubes were dead straight, not a bit of movement at the wheel, so that rules one thing out I guess.

That's a fairly substantial looking fork brace you have there, is that home made or can they be bought somewhere?

That's a fairly substantial looking fork brace