- here is a clutch modification done by fellow xsler peter von sphinx feat. herbert claeren...he is running a long-stroke 880ccm motor...this is designed to deal with the xstra loads of high performance motors and sidecars

- my winter get away will be to create one similar with a billet basket im waiting for-strong, doesnt get the chattering wear...the process will be the same, the xsact ammount removed will depend on the dimensions of the parts used...i will also be fixing a high ratio primary drive gear-4 teeth less-to the basket and the opposing-4 teeth more-gear to the crank

- this should be possible for all clutch variants but careful measurement first is cheap insurance

- i will combine this with an hydraulic clutch operator

- also need to allow about 2.5mm for separation

- 4.4mm gained from turning approx 2.0mm from the inside surface of the boss and approx 2.5mm from the inside surface of the pressure plate

- 2.5mm gained by removing 1.5mm from the bottom of the boss and1.0mm from the outside of the pressure plate

- removing the 2.5mm from the boss underside requires filing the friction plate dog spaces in the basket

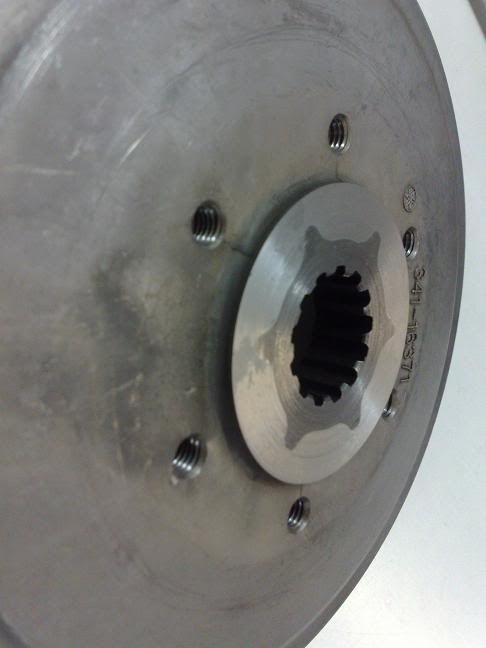

- use the pressure plate with the teeth and make sure that the teeth locate into the boss splines at all times

...2.0mm removed

...side view

...1.5mm from the bottom

...file to fit

...so

...2.5mm thinner

...1.0mm for clearance

...complete

...XJ900 springs

- my winter get away will be to create one similar with a billet basket im waiting for-strong, doesnt get the chattering wear...the process will be the same, the xsact ammount removed will depend on the dimensions of the parts used...i will also be fixing a high ratio primary drive gear-4 teeth less-to the basket and the opposing-4 teeth more-gear to the crank

- this should be possible for all clutch variants but careful measurement first is cheap insurance

- i will combine this with an hydraulic clutch operator

- 8 friction plates @ 3.0mm...24.0mm

- 7 steel plates @ 1.4mm...9.8mm

- 33.8mm...original 7-6...29.4mm......4.4mm difference

- this is the xstra ammount of space required inside the mechanism- also need to allow about 2.5mm for separation

- 4.4mm gained from turning approx 2.0mm from the inside surface of the boss and approx 2.5mm from the inside surface of the pressure plate

- 2.5mm gained by removing 1.5mm from the bottom of the boss and1.0mm from the outside of the pressure plate

- removing the 2.5mm from the boss underside requires filing the friction plate dog spaces in the basket

- use the pressure plate with the teeth and make sure that the teeth locate into the boss splines at all times

...2.0mm removed

...side view

...1.5mm from the bottom

...file to fit

...so

...2.5mm thinner

...1.0mm for clearance

...complete

...XJ900 springs

Last edited: