My guess would be the mileage was when it was performed and they left it up to the owner to decide the interval/mileage they wanted the next one performed at.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Getting the ‘57 beetle back on the road in 2024

- Thread starter bosco659

- Start date

Hooked up the starter to my XS battery and energized the solenoid. Got a sharp click noise but the starter didn’t spin. I grabbed the starter shaft and worked it back and forth. Tried again and success! . I suppose the brushes had been sitting on the same spot on the commutator for 50+ years and had a bad connection. I’ll reinstall it tomorrow. Also found a box of parts I was looking for, including new swing axle boots!

. I suppose the brushes had been sitting on the same spot on the commutator for 50+ years and had a bad connection. I’ll reinstall it tomorrow. Also found a box of parts I was looking for, including new swing axle boots!

Picked up my spray tent too. Need to get a filter; 20” box fan and some plywood and I’m ready to paint a few bits! I wonder if my wife would mind if I tested it in the basement?

The portable spray booth is in! It actual creates a nice gentle draft and should work well. 20x20 filter and a 20” box fan move the air. Looks like the filter will clog up quickly. These parts have been painted by brush with POR15. I’ll top coat them with Tremclad.

Axle seals are in so reassembly should take place near the end of the week.

Axle seals are in so reassembly should take place near the end of the week.

Not the best day in beetle world although got some stuff done.

- had a friend turn my rear brake drums. I was lucky he was able to do it because auto shops around here don’t seem to turn drums and rotors anymore. It’s all throw away now.

- did an actual test of the spray tent. Works well to capture overspray but no fault of the tent, the paint fumes were wicked. I think I’ll need to open my roof vent back up. POR15 on tge drums with a top cost of Tremclad Hi Performance paint. I like it because it dries quickly but man does it stink!

- found I still need to buy one seal for each side of the rear axles before I can button it up. More $ and I don’t want to build up another free shipping order at this time.

- tried citric acid rust removal with the ultrasonic cleaner. I had mixed results. Some pieces cleaned right up in 30 minutes, others not so good after an hour. It does seem like a fast process. I think there isn’t a magic pill for rust removal. It’s a combination of several processes. I’ve tried about 5 of them and bottom line ended up with decent looking results.

- worst news is my LR swing arm is seized in the down position. I’ve tried jacking it and beating it (gently) with an 8 pounder but no movement. I’m soaking the joint in penetrating oil right now. Fingers crossed it’s not a huge job.

- had a friend turn my rear brake drums. I was lucky he was able to do it because auto shops around here don’t seem to turn drums and rotors anymore. It’s all throw away now.

- did an actual test of the spray tent. Works well to capture overspray but no fault of the tent, the paint fumes were wicked. I think I’ll need to open my roof vent back up. POR15 on tge drums with a top cost of Tremclad Hi Performance paint. I like it because it dries quickly but man does it stink!

- found I still need to buy one seal for each side of the rear axles before I can button it up. More $ and I don’t want to build up another free shipping order at this time.

- tried citric acid rust removal with the ultrasonic cleaner. I had mixed results. Some pieces cleaned right up in 30 minutes, others not so good after an hour. It does seem like a fast process. I think there isn’t a magic pill for rust removal. It’s a combination of several processes. I’ve tried about 5 of them and bottom line ended up with decent looking results.

- worst news is my LR swing arm is seized in the down position. I’ve tried jacking it and beating it (gently) with an 8 pounder but no movement. I’m soaking the joint in penetrating oil right now. Fingers crossed it’s not a huge job.

worst news is my LR swing arm is seized in the down position. I’ve tried jacking it and beating it (gently) with an 8 pounder but no movement. I’m soaking the joint in penetrating oil right now. Fingers crossed it’s not a huge job.

Don't discount that it could be the shock seized up.

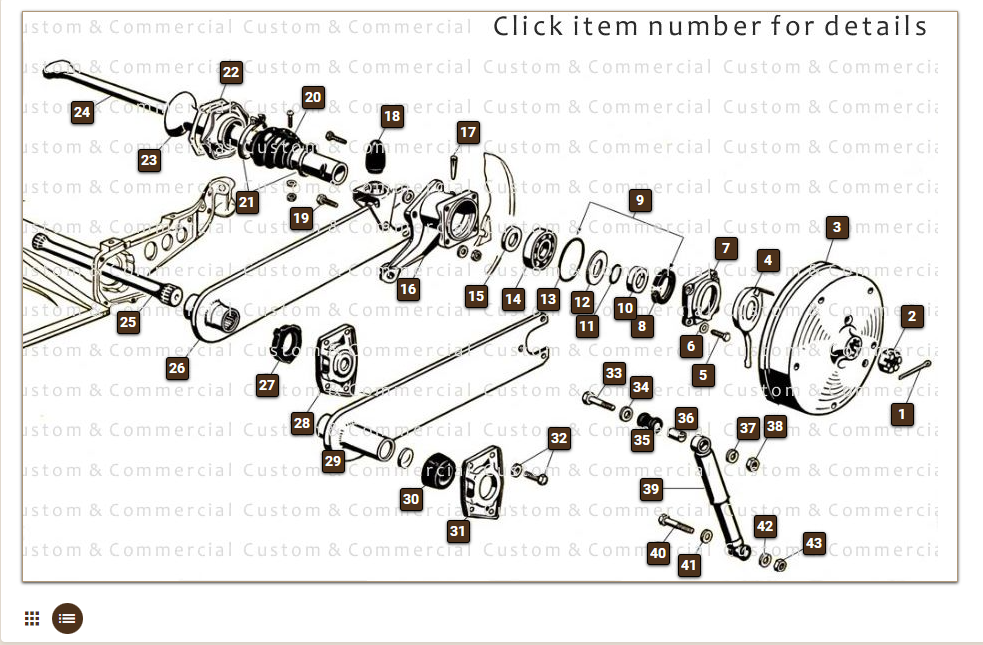

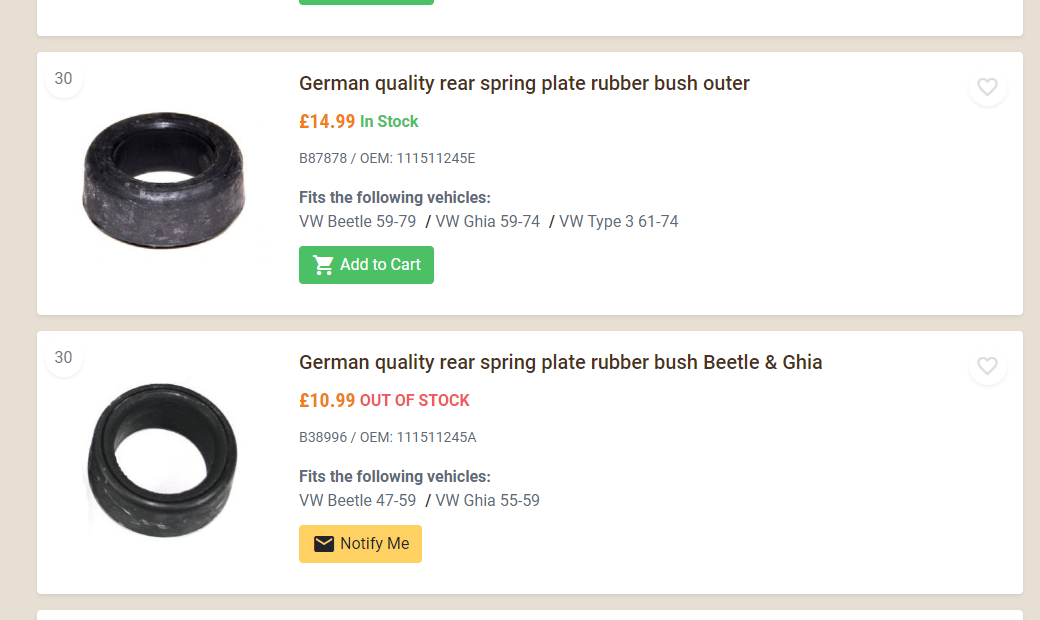

Anything's possible, but I've never seen the torsion bar pivot seize up. Iirc, the bushing out there is a rubber doughnut (for road noise reduction). Can't really envision that seizing.

Found it... yes, that's bushed with a big rubber doughnut.

https://www.customandcommercial.com...rear_axle_parts/beetle_rear_swing_axle_parts/

https://www.customandcommercial.com...rear_axle_parts/beetle_rear_swing_axle_parts/

Last edited:

Thx Jim. I did remove the shock and no go.Don't discount that it could be the shock seized up.

Anything's possible, but I've never seen the torsion bar pivot seize up. Iirc, the bushing out there is a rubber doughnut (for road noise reduction). Can't really envision that seizing.

The gap between 31 & 29 isn’t huge. Long shot but if it sat for 50+ years in this position, could rust have formed between these bits “seizing“ it up? It’s quite a large surface area. I’ll remove the cap tomorrow and report my findings. Looking at the exploded diagram it seems very simple with little to go wrong.

The gap between 31 & 29 isn’t huge. Long shot but if it sat for 50+ years in this position, could rust have formed between these bits “seizing“ it up? It’s quite a large surface area. I’ll remove the cap tomorrow and report my findings. Looking at the exploded diagram it seems very simple with little to go wrong.

Most of my VW experience is from the 70's, so take it with a grain of salt... but yeah, seems like it's pretty straight forward work on the torsion bars and bits for 'em.

Went out to tackle the siezed arm. Put the jack under the shock mount and got a bit of movement. Did the penetrating oil overnight help? Popped off the cap on the swing arm and the rubber bushing was I good shape. Tried the hack again and got better movement. I noticed when I jacked the car under the tranny, the left side was always higher than the right. Then the light went on. The left front suspension was also seized. When I jacked the left swing arm the right front suspension would compress and less force was being applied to the swingarm. On the rhs, when I jacked it, since the left front was siezed, all the force was applied to the swingarm and it compressed more. Dunno if the explanation makes sense. Anyway, good news bad news…. Now I know I’m in for some work on the front.

I’m keeping all fingers crossed the LF problem is a seized shock.

I’m keeping all fingers crossed the LF problem is a seized shock.

Last edited:

Just as a side question. Are you planning on removing the front suspension parts? Namely the front torsion bars.

Not sure of the 1957 but know some VW's have what looks like maybe 3/4 inch wide and 1/8 thick flat bars stacked up in the tubes for front suspension. What I'm looking for is how thick the bars are. I believe some models use different thicknesses, or maybe more than one thickness in one stack.

Might sound odd but there are some older California Sidecars that use sections of those VW torsion bars for their torsion bars.

Not sure of the 1957 but know some VW's have what looks like maybe 3/4 inch wide and 1/8 thick flat bars stacked up in the tubes for front suspension. What I'm looking for is how thick the bars are. I believe some models use different thicknesses, or maybe more than one thickness in one stack.

Might sound odd but there are some older California Sidecars that use sections of those VW torsion bars for their torsion bars.

Hopefully I won’t have to dismantle the front end but if I do I can measure the bars and let you know. Might be after Christmas.Just as a side question. Are you planning on removing the front suspension parts? Namely the front torsion bars.

Not sure of the 1957 but know some VW's have what looks like maybe 3/4 inch wide and 1/8 thick flat bars stacked up in the tubes for front suspension. What I'm looking for is how thick the bars are. I believe some models use different thicknesses, or maybe more than one thickness in one stack.

Might sound odd but there are some older California Sidecars that use sections of those VW torsion bars for their torsion bars.

One of 4 done. Still need to fab brake lines. Quick paint of swing tubes done too. Problem is the Honda comes home tomorrow and I must equally divide my time between the two projects. Something tells me the Honda will get a bit more attention for a week or so.

Last edited:

Well, it took a few days to get that way....but takes a looong time.

I can’t imagine doing a complete restoration. Not for me anyway at this point in my life.Well, it took a few days to get that way....

I can’t imagine doing a complete restoration. Not for me anyway at this point in my life.

Oh c’mon now, you know you want to!

My OCD would be kicking into high gear about now.

Your brakes came out great!

Looking good there, Bosco!Pretty pleased with the results but takes a looong time.

If I may comment...constructively I hope. The rust removal /parts cleaning process is what's killing your timeline. The process of degrease/scrape/wire brush/ electrolysis/more wire brush/more electrolysis/Evaporust etc is far too lengthy. The solution is to simply degrease and sandblast. The part is then ready for paint. Even the smallest Princess Auto /Harbor Freight blast cabinet will make a world of difference, IMO. This is of course provided that your compressor can keep up with the demand.

I think I may have mentioned it previously, but I use a homemade blast cabinet (a plywood box with a glass lid and a pair of gloves through the side), a CTC or Princess Auto blast gun and Black Diamond coal slag from Tractor Supply at $13 a bag, which I re-use ad infinitum. Should give it a try, even if you only use a self-contained blast gun from Princess.

My compressor isn’t a toy but doesn’t deliver enough cfm to keep up with a blast cabinet. If space would allow I’d have a sandblast cabinet and large compressor. I have just enough power in the garage to run a 5hp motor @ 220v, so that isn’t a problem. The brakes are the only part of this project that I plan on for significant rust removal. I know the processes I’m using are lengthy but they have also been cost effective. Hopefully I won’t run into any more surprises.

The engine and components are clean. The tin shrouds are oily and dirty but no need to remove rust there.

This whole rust removal task has been a great learning experience for me.

Your comments and suggestions are appreciated.

The engine and components are clean. The tin shrouds are oily and dirty but no need to remove rust there.

This whole rust removal task has been a great learning experience for me.

Your comments and suggestions are appreciated.

Last edited:

Similar threads

- Replies

- 8

- Views

- 289