-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done to your XS today?

- Thread starter I am Carbon

- Start date

-

- Tags

- maintenance

Bob Wegman

XS650 Enthusiast

I removed the engine from my XS frame today. Need to clean the frame and paint it. Engine needs a good outside cleaning and maybe a refresh of the top end, etc, etc. We shall see where this ends up.

Yamaha Graveyard

XS650 Enthusiast

At that point you should be good for another 40 yearsGetting my new to me XS in reliable riding condition.

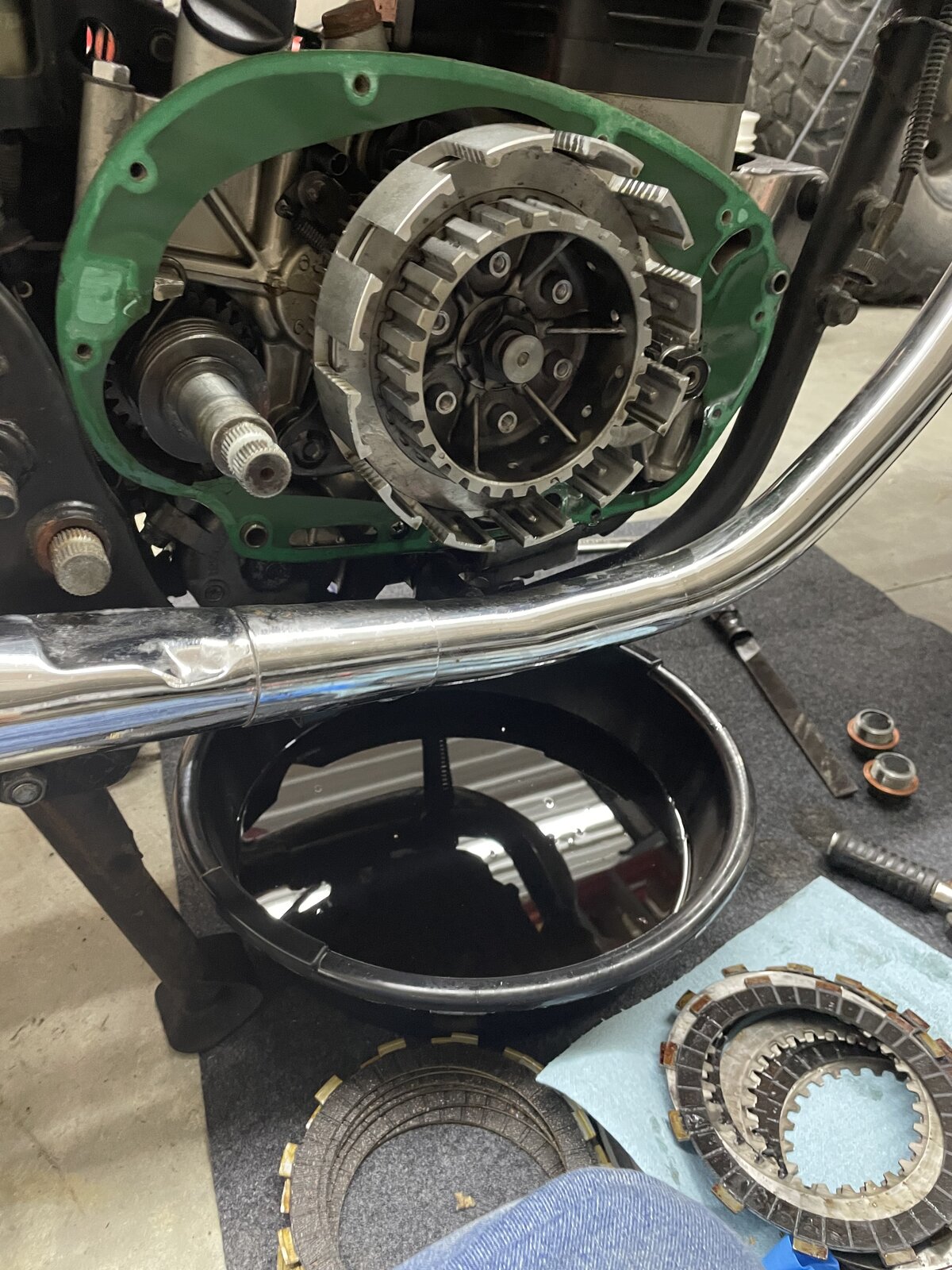

Replaced my sprockets, chain, clutch push rod bushing and seal, clutch cable and lever.

View attachment 227999

View attachment 228000

View attachment 228001

View attachment 228002

Haven't got the rear wheel on yet to ride it but the friction comparison between the old clutch cable and new one is a night and day difference. The lever slop is also substantially improved. I suspect the cable friction may have contributed to my clutch slipping issues but regardless I've already got a new clutch in hand so I'm still going to replace the clutch friction plates and springs next. At that point I'll at least know what I'm dealing with.

Yamaha Graveyard

XS650 Enthusiast

Awesome scooter! you guys on the other side of the pond, Oooo we! What are the forks and trees off and who's rear brake it that rotor and caliper?THE WELSH FLAT TRACKER

A good clean and polish today. Hoping the weather will be good enough for a run out on Sunday

View attachment 228004

View attachment 228005

Mate, that's looking awesome, even the wife likes itTHE WELSH FLAT TRACKER

A good clean and polish today. Hoping the weather will be good enough for a run out on Sunday

View attachment 228004

View attachment 228005

@Yamaha Graveyard @OldfartaussieAwesome scooter! you guys on the other side of the pond, Oooo we! What are the forks and trees off and who's rear brake it that rotor and caliper?

Thanks for the kind words.

Front end is off a Ducati (dont know model; from breakers) including caliper & rotor.

Front (and rear) wheel is off Husqvarna (Again from breaker).

Rear now has Cognito Moto hub custom built locally.

Rear brake caliper: Brembo / Rotor is:

Full build renovation is here: https://www.xs650.com/threads/welsh-flat-track-revival.60449/

Build sheet here: https://www.xs650.com/threads/welsh-flat-track-revival.60449/page-8 #158

My wife also likes it but was p*ssed when she noticed its a single seat!

Last edited:

Oh, c'mon Ads, there's plenty of room for two on the seat - just that there's no rear pegs . . .My wife also likes it but was p*ssed when she noticed its a single seat!

j343my

XS650 Enthusiast

Did the old squeeze the spring in a vice trick to try to get the starter to work on my '84 today. It worked as far as the starter will start the bike now, but it still sounds like its grinding. Is that normal or did I not do something properly?

Well, that's hard to say. Did you test it with a fishing scale to see if, indeed, it did get tighter, and now has maybe 6 lbs or better of friction before it spins? Even "fixed" though, these starters still aren't the greatest. Best to get the bike tuned well so it starts quickly and easily. That way you minimize the strain on the starter.

j343my

XS650 Enthusiast

I did test it. I got over 6 lbs before it spins.Well, that's hard to say. Did you test it with a fishing scale to see if, indeed, it did get tighter, and now has maybe 6 lbs or better of friction before it spins? Even "fixed" though, these starters still aren't the greatest. Best to get the bike tuned well so it starts quickly and easily. That way you minimize the strain on the starter.

The bike is tuned well and fires up on the first kick usually, so it shouldn't be too much strain on the starter.

I own two XS650s and I've never started one with the starter before today so I didn't know what to expect. I don't know if they are always a bit grindy.

NewToXs

XS650 Enthusiast

I put my new clutch plates in today and new springs. The old plates definitely needed replacement but think the springs were ok. The springs were still in spec but the new springs are stiffer. I may wind up swapping the old springs back if the pull is too much.

It's hard to tell from the pic, but it appears the clutch basket may have developed some grooves where the fiber plates ride. If you have occasion to have to go back in there, dress them smooth with a file.I put my new clutch plates in today and new springs

NewToXs

XS650 Enthusiast

No grooves. What you see is polish marks, you can’t feel them running your finger across them.It's hard to tell from the pic, but it appears the clutch basket may have developed some grooves where the fiber plates ride. If you have occasion to have to go back in there, dress them smooth with a file.

That looks pretty good to me - well done! I wouldn't try to squeeze an extra row of holes. In principle, the holes should sweep the entire friction area under the pads.

How do you avoid swarf in yer coffee, or don't you mind?

How do you avoid swarf in yer coffee, or don't you mind?

Yes, one last hole near the outer edge would be good, just don't get it too close to the outer edge. As it stands now, your pattern isn't covering the whole swept area of the disc. That means the holes won't cover and scrape clean the whole pad surface. You might also consider enlarging the middle holes in each "swirl". For best cooling, you want to create as much extra surface area as possible. You will do that by making the holes the same size as the disc is thick. Here's how I do mine. I made my pattern up to use 5mm holes so I can't really enlarge the 1st and last hole in each "swirl", so I just enlarge the middle ones. These discs are 7mm thick when new and since I'm dealing with used ones, I use a 6.9mm drill bit to enlarge the holes .....

Supplementary iron! Thanks Raymond, it worked out well.That looks pretty good to me - well done! I wouldn't try to squeeze an extra row of holes. In principle, the holes should sweep the entire friction area under the pads.

How do you avoid swarf in yer coffee, or don't you mind?

This is a 7mm disc with 5.5mm holes, do you think I can enlarge them to 7mm without being too close together? The added outer and inners I could leave at 5.5mmYes, one last hole near the outer edge would be good, just don't get it too close to the outer edge. As it stands now, your pattern isn't covering the whole swept area of the disc. That means the holes won't cover and scrape clean the whole pad surface. You might also consider enlarging the middle holes in each "swirl". For best cooling, you want to create as much extra surface area as possible. You will do that by making the holes the same size as the disc is thick. Here's how I do mine. I made my pattern up to use 5mm holes so I can't really enlarge the 1st and last hole in each "swirl", so I just enlarge the middle ones. These discs are 7mm thick when new and since I'm dealing with used ones, I use a 6.9mm drill bit to enlarge the holes .....

View attachment 228176

I can see from your pic that the inner hole you have now is perfect, right at the edge of the swept area, so you needn't add a hole there, just on the outside. I'm not sure if enlarging them would make them too close together. Maybe you could "draw" them larger with a Sharpie to see. Or if you are concerned about it, maybe just enlarge every other hole?

Similar threads

- Replies

- 32

- Views

- 1K