I had similar problems using an electronic tach (multiple wraps around spark plug wire) the RPM's jumped all over the place...AS WELL AS...it would kill spark on that cylinder every now and then. I ended up going with a mechanical tach to keep it simple. I am now using the electronic tach on my generator to gauge hours used...single cylinder, no issues. I'm sure there's a solution or these wouldn't exist...but I gave up after trying various #'s of wraps and alternate wiring methods.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Winter project: upgrading time! (R6 forks and more...)

I cannot see how a tacho can read from coil +. That terminal should have pretty constant voltage.Have you tried Option 1 where the tacho is connected to the +ve of the ignition coil? This can be more stable than Option 2.

Coil - (negative, the one that is connected to the points or black box), on the other hand, has something approaching a square pulse, +12V when points are open, close to 0V when points are closed. Pretty much the same with an electronic battery ignition.

From the Carmo website:

- The unit is protected against overvoltage (defect voltage regulator/rectifier, bad battery, ...).

- The unit is protected against a defect ignition coil and reverse battery connection.

- The unit has a acceleration correction, when the bike rev's up the ignition delay will be a bit more (in proportion). Smoother acceleration.

- The unit uses digital technique, so it is more accurate and temperature changes have no influence, the curve is also optimized for more power.

- When the battery voltage changes the unit will change the control to the ignition coil so the spark power will stay the same.

- Start mode, during engine start the unit will give more current to the ignition coil for a faster start.

Nice guarantee of 3 Years and good protection circuitry - I assume the overvoltage protection has now paid off. I see the coil gets a current boost at startup so this explains the easy engine start in the video.

All good stuff!

- The unit is protected against overvoltage (defect voltage regulator/rectifier, bad battery, ...).

- The unit is protected against a defect ignition coil and reverse battery connection.

- The unit has a acceleration correction, when the bike rev's up the ignition delay will be a bit more (in proportion). Smoother acceleration.

- The unit uses digital technique, so it is more accurate and temperature changes have no influence, the curve is also optimized for more power.

- When the battery voltage changes the unit will change the control to the ignition coil so the spark power will stay the same.

- Start mode, during engine start the unit will give more current to the ignition coil for a faster start.

Nice guarantee of 3 Years and good protection circuitry - I assume the overvoltage protection has now paid off. I see the coil gets a current boost at startup so this explains the easy engine start in the video.

All good stuff!

My bike with TCI uses the +ve. A quick google search shows +ve used also for CDI, but all the points ignition diagrams I glanced seem to be using -ve coil terminal. I am not sure of the full explanation.

I came up with a depth from the machined flat surface on the face of the stator to the slip ring on the rotor of 9.6mm. give or take a .1mm just on a random motor sitting in the shop.

Bjorn

XS650 Addict

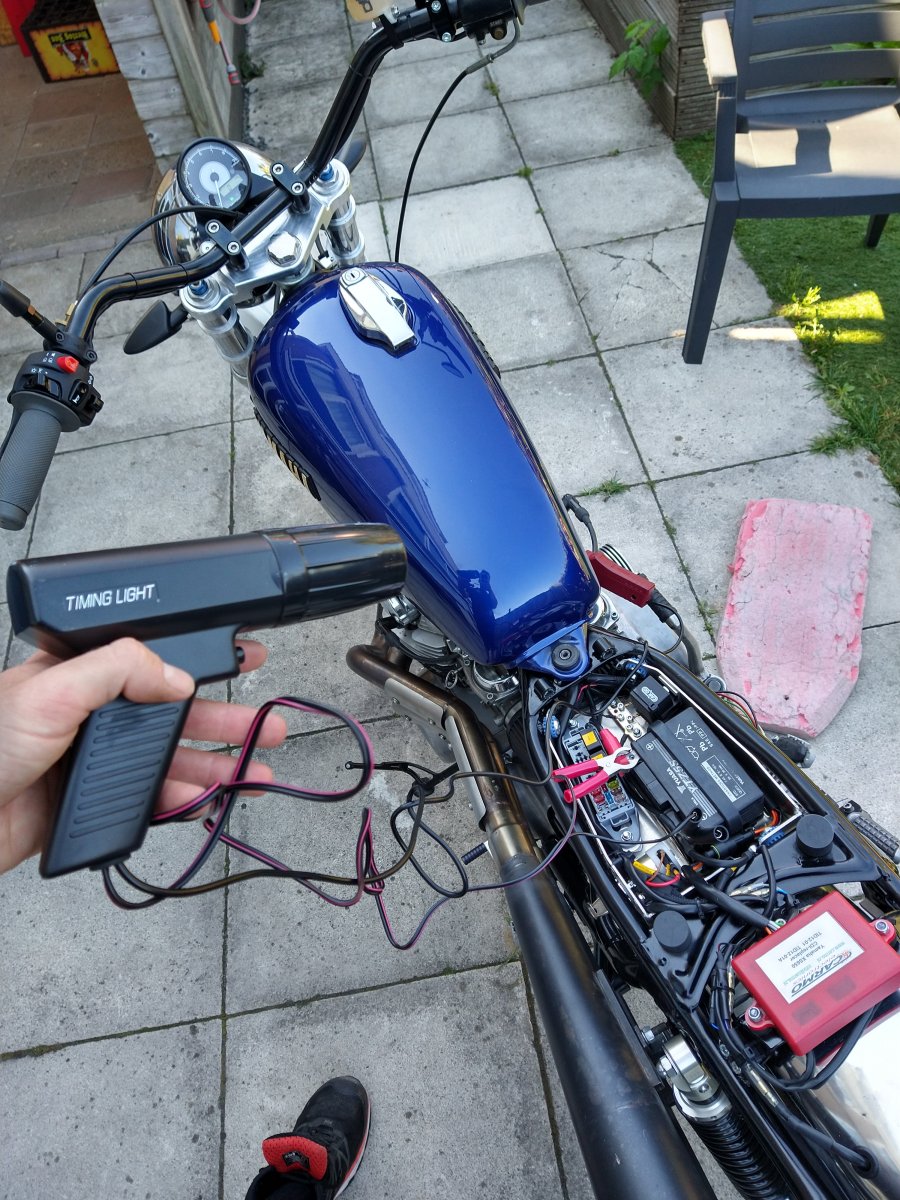

So this morning I unhooked the tacho pick up from the LHS coil lead. Here is a picture of the current situation with the tape already removed:

Put the tank back on and let it warm up.

Apart from warming up with some choke/enrichment it looks pretty normal to me. In this situation I also checked the timing with the timing light. And here I found something interesting I can't really explain. The timing light would be flashing inconsistent in a random ish pattern if it was connected to the LHS coil lead. However when I put it on the RHS lead it would be stable!

Timing seems to be ok btw, it's stable and advancing with revs.

With this in mind I swapped the tacho pickup to the RHS lead. And behold the video below, RPMs look stable and no weirdness. I might try the other methods of picking it up from the coil +.

Anyone have an idea why we see this?

Put the tank back on and let it warm up.

Apart from warming up with some choke/enrichment it looks pretty normal to me. In this situation I also checked the timing with the timing light. And here I found something interesting I can't really explain. The timing light would be flashing inconsistent in a random ish pattern if it was connected to the LHS coil lead. However when I put it on the RHS lead it would be stable!

Timing seems to be ok btw, it's stable and advancing with revs.

With this in mind I swapped the tacho pickup to the RHS lead. And behold the video below, RPMs look stable and no weirdness. I might try the other methods of picking it up from the coil +.

Here is one theory: On a dual coil like you have, the high voltage current flows from one plug to the other. Or put differently, one spark plug and HT cable has reversed current compared to the other. So if you wrap the wire the same direction on the RH as you did on the LH, the polarity of the signal would end up opposite. At least that is the conventional induction/ current/ polarity principle that applies to any winding.

I do not know how the TCI operates, but generally, battery ignition (points, boyer, newrtonics, etc) have a constant 12 V supply to the coil +, while coil - is periodically connected to ground via points or black box. When this connection is interrupted (I.e points open), the coils magnetic field collapses, and a high voltage pulse is induced in the secondary winding of the coil. With CDI, it is opposite, the CDI box discharges a strong pulse through the primary winding, rapidly building a magnetic field, and inducing a high voltage pulse in the secondary winding. It is the rate of change of the magnetic flux that determining secondary voltage, it does not matter whether the flux is increasing or decreasing.My bike with TCI uses the +ve. A quick google search shows +ve used also for CDI, but all the points ignition diagrams I glanced seem to be using -ve coil terminal. I am not sure of the full explanation.

The rev counter digital display is flickering is that only in the video or in real life also.

? Voltage supply meter ? / ? Voltage supply on bike ? / Defect meter ? does it flick not running ? / Ground ?

What is the cause and what is the effect ?

The rev counter appears to work on the right side but not left

That can be the signal in the coil lead or the pickup.

If the signal in the ignition is erratic ( fex poor ground ) then the rev counter can malfunction on ) that side.

There is mention of strobe light displaying different

2 problems described on the left side not there at the right side.

The timing light would be flashing inconsistent in a random ish pattern if it was connected to the LHS coil lead. However when I put it on the RHS lead it would be stable!

If one would work on that .? Thinking out loud Shifting the spark plug cap ( perhaps also plugs ) right to left and left to right

See if anything moves.

? Voltage supply meter ? / ? Voltage supply on bike ? / Defect meter ? does it flick not running ? / Ground ?

What is the cause and what is the effect ?

The rev counter appears to work on the right side but not left

That can be the signal in the coil lead or the pickup.

If the signal in the ignition is erratic ( fex poor ground ) then the rev counter can malfunction on ) that side.

There is mention of strobe light displaying different

2 problems described on the left side not there at the right side.

The timing light would be flashing inconsistent in a random ish pattern if it was connected to the LHS coil lead. However when I put it on the RHS lead it would be stable!

If one would work on that .? Thinking out loud Shifting the spark plug cap ( perhaps also plugs ) right to left and left to right

See if anything moves.

Bjorn

XS650 Addict

I do not know how the TCI operates, but generally, battery ignition (points, boyer, newrtonics, etc) have a constant 12 V supply to the coil +, while coil - is periodically connected to ground via points or black box. When this connection is interrupted (I.e points open), the coils magnetic field collapses, and a high voltage pulse is induced in the secondary winding of the coil. With CDI, it is opposite, the CDI box discharges a strong pulse through the primary winding, rapidly building a magnetic field, and inducing a high voltage pulse in the secondary winding. It is the rate of change of the magnetic flux that determining secondary voltage, it does not matter whether the flux is increasing or decreasing.

My knowledge stops here haha. I don't think I understand all the principals involved to fully grasp what going on.

On the other hand, bike seems te be running .... And tach is working fine on this side

Bjorn

XS650 Addict

The rev counter digital display is flickering is that only in the video or in real life also.

? Voltage supply meter ? / ? Voltage supply on bike ? / Defect meter ? does it flick not running ? / Ground ?

What is the cause and what is the effect ?

The rev counter appears to work on the right side but not left

That can be the signal in the coil lead or the pickup.

If the signal in the ignition is erratic ( fex poor ground ) then the rev counter can malfunction on ) that side.

There is mention of strobe light displaying different

2 problems described on the left side not there at the right side.

The timing light would be flashing inconsistent in a random ish pattern if it was connected to the LHS coil lead. However when I put it on the RHS lead it would be stable!

If one would work on that .? Thinking out loud Shifting the spark plug cap ( perhaps also plugs ) right to left and left to right

See if anything moves.

I don't think I can follow you Jan?

When you talk about the ground of the coil, looking at my schematic the coil grounds thru.... The sparkplugs right? What are you referring to?

Looking at the last video there is no flickering of the tacho? If you were referring to the older videos, yes it was there. Also in real life otherwise I would see a problem

I will try the shifting the splugs and leads.

Will also measure the distance between the rotor and the pick up.

I don't think I can follow you Jan?

When you talk about the ground of the coil, looking at my schematic the coil grounds thru.... The sparkplugs right? What are you referring to?

Looking at the last video there is no flickering of the tacho? If you were referring to the older videos, yes it was there. Also in real life otherwise I would see a problem

I will try the shifting the splugs and leads.

Will also measure the distance between the rotor and the pick up.

Maybe I got that wrong sorry about that .

Need to check Carmo better .But the DC system is o top down system

12V to 0 V Like a water hose in the garden

On a stock points bike the coil primary winding's have upside and the downside through the points ( If i remember right. )

If there is a problem with the ground through the points it is like if a fat man has stepped onto the garden Hose.

Restricting the flow and the same for the current trough the primary winding.

So when the point open there is nothing happening Because there was no current to begin with.

And no magnetic field.

So the coil has there 3 wires + in and ground minus via Points and One to spark plugs.

On the coil is the upside Red and the Downside Yellow going into the TCI

What happens inside the TCI is not certain but for a spark the Yellow one or the red must stop the current trough the primary winding

I believe that somewhere there must be a " Perfect " Ground or it will be like the fat man standing on the garden hose.

Restricting primary current and so the secondary spark.

But since the bike runs fine and the meter is working perhaps all is fine.

And some minor difference left to right. But still worth checking Now so it wont manifest itself some rainy night.

Bjorn

XS650 Addict

Weird, I just put on the connector to the old R/R, with the tacho pickup still on the RHS. Now it's all wonky again.....

I'm still curious as to whether you rotor is OEM or a Chinese knockoff?Weird, I just put on the connector to the old R/R, with the tacho pickup still on the RHS. Now it's all wonky again.....

Bjorn

XS650 Addict

I got rid of the twisted pick up wire around the coil lead. I used a jumper like the tacho manual recommend on the + terminal of the coil.

That did nothing, tacho did not show revs.

Put it on the - terminal of the coil, that gave the tacho a signal but it's still not OK. I left the bike idling for a while but the engine is skipping and not running smooth. So still no testride

That did nothing, tacho did not show revs.

Put it on the - terminal of the coil, that gave the tacho a signal but it's still not OK. I left the bike idling for a while but the engine is skipping and not running smooth. So still no testride

Bjorn

XS650 Addict

I came up with a depth from the machined flat surface on the face of the stator to the slip ring on the rotor of 9.6mm. give or take a .1mm just on a random motor sitting in the shop.

Gary I just checked this, on multiple points, get an average of around 9,7mm

Bjorn

XS650 Addict

How can you tell?I'm still curious as to whether you rotor is OEM or a Chinese knockoff?

Bjorn

XS650 Addict

I just removed all the fuses expect the main and the one for the ignition. Bike starts but runs shit like it made no difference..

This bike haunted or what

This bike haunted or what

To recap:

The bike runs great without the digital tach and without the R/R...correct?

Install the tach to the left side plug and it's crap.

Install the tach to the right side plug and it's ok.

Install any R/R and it runs like crap.

Is this an accurate assessment?

The bike runs great without the digital tach and without the R/R...correct?

Install the tach to the left side plug and it's crap.

Install the tach to the right side plug and it's ok.

Install any R/R and it runs like crap.

Is this an accurate assessment?

Bjorn

XS650 Addict

To recap:

1. The bike runs great without the digital tach and without the R/R...correct?

2. Install the tach to the left side plug and it's crap.

3. Install the tach to the right side plug and it's ok.

4. Install any R/R and it runs like crap.

Is this an accurate assessment?

1. With the new (non-charging) R/R it seemed to run good. Short test though.

2. Yes, this was tested with and old R/R.

3. Yes at first, but after not really changing anything later on the day this would result in the bike running rough.

4. Basically with any of the old R/R, yes.

Can someone confirm its save to start the bike without an R/R hooked up? I will repeat point 1.

Similar threads

- Replies

- 6

- Views

- 2K