XS650 Clutch cable experiments and tidbits

This is a companion piece to the XS650 clutch actuator experiments:

Clutch worm actuator experiment and tidbits

Clutch worm mod testing

Clutch pushrod experiment and tidbits

I've rounded up 5 different clutch cables to be measured/tested/evaluated. They are:

1 - 650Central EZ-Pull cable, 2.5mm (0.100") core diameter, no elbow.

2 - Motion Pro 05-0013, 2.5mm (0.100") core diameter , 12° elbow

3 - My old cable (16 yrs old, from Yamaha, similar to Motion Pro), 2.5mm (0.100") core diameter , 18° elbow

4 - MikesXS 51-6502 (KSI 3L1-26335-00), acquired several years ago, 2mm (0.080") core diameter , 20° elbow

5 - Yamaha 447-26335-00, 2mm (0.080") core diameter , 30° elbow

The 650Central EZ-Pull cable is an elbowless, straight-in cable setup. The cable sheath end fitting that fits into the sidecover has a very small shoulder, so a brass shoulder was made and press-fitted onto the end. The free length of the core cable is about 1/2" longer than the other cables, a feature that is supposed to ensure that the clutch worm arm doesn't overtravel into the less-advantageous leverage zone. The core cable is also unique in that it isn't the single spiral wound type. It looks to be the 7x7 multi-strand type. The overall length of the cable is a bit longer than stock.

The MikesXS clutch cable may be a different design by now, so it's tests may be outdated and irrelevant. If anyone has a new version, please post it up here.

Please feel free to post up any additional, contributing, info on our clutch cables. Info on new/different cables, routing techniques, pro's/con's, whatever, are greatly encouraged.

To reduce confusion, testing will be done in the above 1-5 order, and pics that show these cables will have the cables placed in the above 1-5 order.

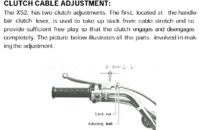

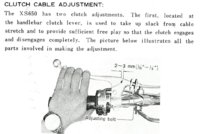

What we're looking for is any differentiating features that may lead to reduced clutch lever pull, increased worm/actuator arm travel, and clutch disengagement action. The cable core design will influence friction and tension stretching. The sheath must endure compression forces, and should have a liner to reduce friction. Three factors work against getting full mechanism travel; core stretch, sheath compression, and liner squash (the core tries to gouge into the softer liner on the short radius of a curved cable). I believe that increased tension of the core results in a non-linear compounded increase in friction, due to this gouging, and any reduction in cable tension will result in greater-than-expected reduction in friction. The notorious cable elbow must surely contribute to friction, hopefully these tests will quantify that effect.

First, let's look at the cables:

This is a companion piece to the XS650 clutch actuator experiments:

Clutch worm actuator experiment and tidbits

Clutch worm mod testing

Clutch pushrod experiment and tidbits

I've rounded up 5 different clutch cables to be measured/tested/evaluated. They are:

1 - 650Central EZ-Pull cable, 2.5mm (0.100") core diameter, no elbow.

2 - Motion Pro 05-0013, 2.5mm (0.100") core diameter , 12° elbow

3 - My old cable (16 yrs old, from Yamaha, similar to Motion Pro), 2.5mm (0.100") core diameter , 18° elbow

4 - MikesXS 51-6502 (KSI 3L1-26335-00), acquired several years ago, 2mm (0.080") core diameter , 20° elbow

5 - Yamaha 447-26335-00, 2mm (0.080") core diameter , 30° elbow

The 650Central EZ-Pull cable is an elbowless, straight-in cable setup. The cable sheath end fitting that fits into the sidecover has a very small shoulder, so a brass shoulder was made and press-fitted onto the end. The free length of the core cable is about 1/2" longer than the other cables, a feature that is supposed to ensure that the clutch worm arm doesn't overtravel into the less-advantageous leverage zone. The core cable is also unique in that it isn't the single spiral wound type. It looks to be the 7x7 multi-strand type. The overall length of the cable is a bit longer than stock.

The MikesXS clutch cable may be a different design by now, so it's tests may be outdated and irrelevant. If anyone has a new version, please post it up here.

Please feel free to post up any additional, contributing, info on our clutch cables. Info on new/different cables, routing techniques, pro's/con's, whatever, are greatly encouraged.

To reduce confusion, testing will be done in the above 1-5 order, and pics that show these cables will have the cables placed in the above 1-5 order.

What we're looking for is any differentiating features that may lead to reduced clutch lever pull, increased worm/actuator arm travel, and clutch disengagement action. The cable core design will influence friction and tension stretching. The sheath must endure compression forces, and should have a liner to reduce friction. Three factors work against getting full mechanism travel; core stretch, sheath compression, and liner squash (the core tries to gouge into the softer liner on the short radius of a curved cable). I believe that increased tension of the core results in a non-linear compounded increase in friction, due to this gouging, and any reduction in cable tension will result in greater-than-expected reduction in friction. The notorious cable elbow must surely contribute to friction, hopefully these tests will quantify that effect.

First, let's look at the cables: