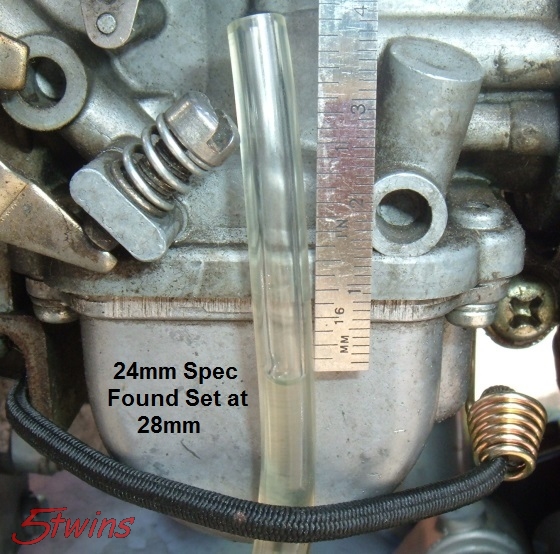

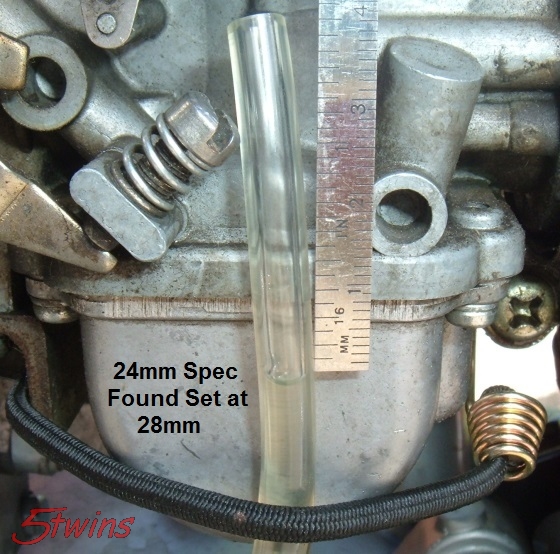

No or limited response from mix screw adjustments can also be caused by float levels being off. Have you tried checking fuel levels with the clear tube method? Yes, measure them but checking with the clear tube really verifies that the setting you measured is what you're actually getting and is correct .....

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XS650 Ignition timing revisited - Are we too advanced?

- Thread starter TwoManyXS1Bs

- Start date

-

- Tags

- electrical engine maintenance

No I haven't tried that. I'm confused by the ruler you have lol!No or limited response from mix screw adjustments can also be caused by float levels being off. Have you tried checking fuel levels with the clear tube method? Yes, measure them but checking with the clear tube really verifies that the setting you measured is what you're actually getting and is correct .....

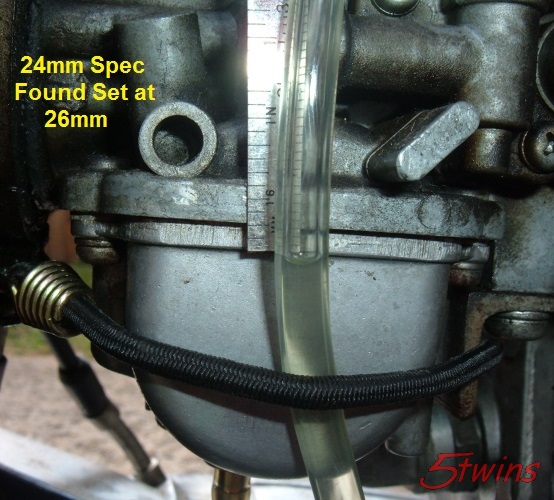

Also, that last pic seems to show the bowl full. All the way to the sealing surface.

Is that correct?

Typically, there is a lip around the bottom of the carb body and the bowl fits in up past it by a couple MM to reach the gasket and sealing surface. So, in that last pic, the fuel level in the bowl isn't quite to the top of it, it's a couple MM below it. Yes, it's almost full, but not quite. When specs are given for checking with a clear tube, this is usually what they want - the fuel level at the joint between the carb and bowl. That "joint" you're looking at isn't the top of the bowl, it's a couple MM lower because the bowl extends up past it.

I held the ruler up to give a rough correlation between the measured setting and what difference it makes in the actual fuel level. For instance, in the 1st pic, the 28mm setting is 4mm off the 24mm spec and that shows as about an 8mm lower fuel level.

I held the ruler up to give a rough correlation between the measured setting and what difference it makes in the actual fuel level. For instance, in the 1st pic, the 28mm setting is 4mm off the 24mm spec and that shows as about an 8mm lower fuel level.

I slotted by '81 pickup top hole (also xsjohn suggestion) to give a base timing of barely inside the inverted U, so minimum factory spec. Result was no power loss or gain going by feel, noticeably throatier sound, zero pinging which was the purpose, possibly cooler running though never measured it. Some year pickups are already slotted, others are just a round hole. If you slot it use a sharp burr like a diamond burr to minimize time and heat on itafter building my LED Ignition Timing Light, I reset my retarded ignition timing back to the factory spec of 40° BTDC full advance.

...

My primitive 'oldschool' understanding of octane ratings was that the higher octanes had a higher flash temperature and a slower, controlled burn, a requirement of the high-compression muscle cars of that time. Folks thought that higher octane gave you more power, but the reverse was true.

...

Comments, guys...?

If i could ask about one more issue...

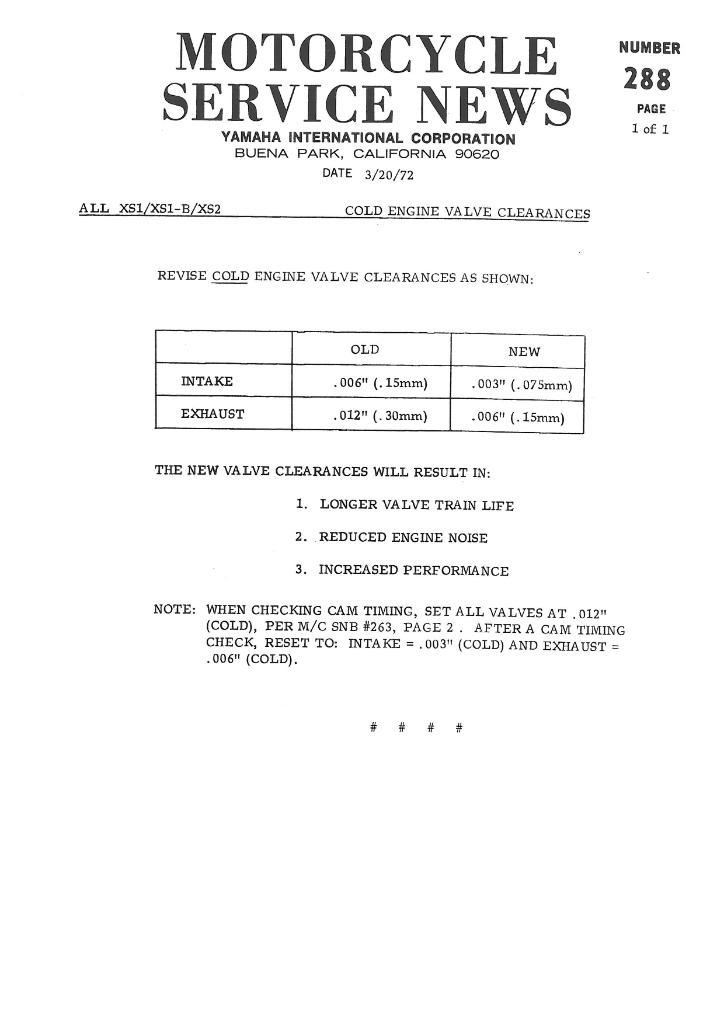

It seems like my valve adjustments are not stable. I put the pistons at TDC and set the clearance, then go for a short ride or 2.

The next day when the bike is completely cold, I recheck and the clearances have increased. Typically the intakes go from .003 (which I've read is a safe place) to maybe .005 or .006.

The exhausts go from .006 to ~.009.

I'm using a torque wrench and tightening the locknuts to 19ft/lbs per the mfr specs.

It seems like my valve adjustments are not stable. I put the pistons at TDC and set the clearance, then go for a short ride or 2.

The next day when the bike is completely cold, I recheck and the clearances have increased. Typically the intakes go from .003 (which I've read is a safe place) to maybe .005 or .006.

The exhausts go from .006 to ~.009.

I'm using a torque wrench and tightening the locknuts to 19ft/lbs per the mfr specs.

^Make sure you turn the crank counterclockwise to get to tdc. If you go past, go around again instead of backing up clockwise. That might cause what you're seeing? Make sure you check clearance again immediately after tightening in case it moved.

Last edited:

At TDC on compression you're about 150° of rotation away from the cam lobes. CW...CCW... overshoot and back up... none of that's gonna make a bit of difference when the ramps are that far away. "About" TDC is plenty close enough... regardless of how you got there.^Make sure you turn the crank counterclockwise to get to tdc. If you go past, go around again instead of backing up clockwise. That might cause what you're seeing? Make sure you check clearance again immediately after tightening in case it moved.

Provided you're double checking after adjustment and verifying the correct clearance, that would indicate some wear on either the cam, rocker or adjuster after you run the engine. And that would definitely be excessive.

Yes I'm triple checking the clearance after tightening.

As I mentioned previously, I replaced the cam and rockers due to wear. I was concerned about top end oil flow so the first time I started it, I left the valve covers off.

Yes, it made a mess but there is definitely oil flow. Also I've looked up past the rockers and so far the cam looks fine so, I'm thinking it's not wear.

That's why I was asking, it didn't make sense. 19ft/lbs on a nut and bolt that size is TIGHT! And when I check them after running, they still seem tight.

As I mentioned previously, I replaced the cam and rockers due to wear. I was concerned about top end oil flow so the first time I started it, I left the valve covers off.

Yes, it made a mess but there is definitely oil flow. Also I've looked up past the rockers and so far the cam looks fine so, I'm thinking it's not wear.

That's why I was asking, it didn't make sense. 19ft/lbs on a nut and bolt that size is TIGHT! And when I check them after running, they still seem tight.

Yeah, if it's not wear... damned if I know.That's why I was asking, it didn't make sense.

Keep in mind... the cam chain is gonna sling "some" oil up there, making it "look like" it's being pumped up there even if it ain't. If I had previous wear issues and wanted to make 100% sure, I'd pull one of the banjo bolts off the oil tube and make sure it's pumping.

Yes, it's very wide there, no doubt wide enough to compensate for slack in chain, etc. Being consistent would counter any unknown weirdness whatever it might be thoughAt TDC on compression you're about 150° of rotation away from the cam lobes. CW...CCW... overshoot and back up... none of that's gonna make a bit of difference when the ramps are that far away. "About" TDC is plenty close enough... regardless of how you got there.

You say you're triple checking the adjustment after setting it but is that with the motor still in the same spot, or have you turned through several revolutions then re-checked? I like to spin the motor over a few times, ending up back at TDC on that cylinder, then re-check.

Often, when you tighten down the lock nut, your adjustment gets a little looser. I think this is due to play in the adjuster screw threads. Tightening the nut down on top takes up that play by lifting the screw towards it, and that results in slightly more clearance. If that happens, I'm usually able to correct it by placing a box wrench on the nut and tapping it a little tighter with a rubber mallet, without holding the adjuster screw while I do it. This turns the screw with the nut and makes it a little tighter, "fixing" the loose clearance issue. I don't go much tighter on the nut, maybe 1/16 to 1/8 of a turn at most. If that doesn't fix the issue then I have to go through the whole adjustment procedure again (loosen the lock nut, adjust the screw).

Have you looked at the tappet and valve stem ends? They are often beat up and chipped, making a precise setting that stays put hard to achieve. For the most part if they don't hammer I just call it life with an XS650 and move on.

i don't use a torque wrench on the tappet nuts. Just use a bit of a quick tug for the final "set" of the nut. This actutally has a bit of science behind it, that initial stuck feel when loosening a nut is the result of micro thread welding, just how threads work. My feeling is the final "sharp" tug encourages the micro welds and keeps the nut from loosening, I've done a bunch of XS650 (and other motors) valve setting have yet to have a nut back off. YNTMV ;^)

(your nut tightening may vary) figgered I better explain cuz I drove a bunch of guys here nuts with gggGary custom acronyms.

i don't use a torque wrench on the tappet nuts. Just use a bit of a quick tug for the final "set" of the nut. This actutally has a bit of science behind it, that initial stuck feel when loosening a nut is the result of micro thread welding, just how threads work. My feeling is the final "sharp" tug encourages the micro welds and keeps the nut from loosening, I've done a bunch of XS650 (and other motors) valve setting have yet to have a nut back off. YNTMV ;^)

(your nut tightening may vary) figgered I better explain cuz I drove a bunch of guys here nuts with gggGary custom acronyms.

I will try the banjo bolt idea just to be double sure. Probably gonna make a mess but better safe than sorry.

I have not tried the logical step of rotating the engine a couple times and recheck. See? That's why we ask the gurus! Lol

I have noticed that sometimes the gap becomes slightly looser as the nut is tightened and have also used the "more torque without holding the adjuster" method.

It's crazy, I'm hoping that at some point it will stop.

I swear, if I cook this motor again I might wash this bike with kerosene and dry it with a match!!

I have not tried the logical step of rotating the engine a couple times and recheck. See? That's why we ask the gurus! Lol

I have noticed that sometimes the gap becomes slightly looser as the nut is tightened and have also used the "more torque without holding the adjuster" method.

It's crazy, I'm hoping that at some point it will stop.

I swear, if I cook this motor again I might wash this bike with kerosene and dry it with a match!!

PS you will never blow up an XS from loose valves. Yamaha originally called out 6 and 12!!!!! No one could stand the hammering so they tightened the spec. LOL

Yes, and to compound it, I think the valve stem is "supposed" to turn, so the irregularities come and go. I agree that if it works it's good is a good philosophy with this particular thing...Have you looked at the tappet and valve stem ends? They are often beat up and chipped, making a precise setting that stays put hard to achieve. For the most part if they don't hammer I just call it life with an XS650 and move on.

Well, not to be a downer, but a forum member did just that a few yrs back. Don't remember who.I swear, if I cook this motor again....

Fresh top end... new cam and rockers. He made one mistake... left the drive pin out of the oil pump inner gear. For about 200 miles he fought valve adjustment issues until he tore the motor back down. Cam and rockers were roached big time. It was @GLJ that pointed out to him the discoloration meant oil starvation. You remember who it was Greg?

I'll be checking the oil pump for sure!! Thanks again everyone for all the help!!Well, not to be a downer, but a forum member did just that a few yrs back. Don't remember who.

Fresh top end... new cam and rockers. He made one mistake... left the drive pin out of the oil pump inner gear. For about 200 miles he fought valve adjustment issues until he tore the motor back down. Cam and rockers were roached big time. It was @GLJ that pointed out to him the discoloration meant oil starvation. You remember who it was Greg?

He had oil on top with the pump not turning.Well, not to be a downer, but a forum member did just that a few yrs back. Don't remember who.

Fresh top end... new cam and rockers. He made one mistake... left the drive pin out of the oil pump inner gear. For about 200 miles he fought valve adjustment issues until he tore the motor back down. Cam and rockers were roached big time. It was @GLJ that pointed out to him the discoloration meant oil starvation. You remember who it was Greg?

Similar threads

- Replies

- 36

- Views

- 1K

- Replies

- 10

- Views

- 523

- Replies

- 32

- Views

- 1K

- Replies

- 32

- Views

- 2K