After working on various other projects (and recovering from a partially torn hip muscle) I finally got back to working on the Parts Bike this week. I decided to tackle putting on the new tires and the first task was to remove the nearly 50 year old tires. Being hard as a rock the old ones put up a pretty good fight but finally came off.

Putting the new tire on the rear was difficult but no worse than others I’ve done in the past. The front however was an entirely different story. It was the hardest tire install, car or bike, I have ever done! I was pulling so hard on the bar it broke the bracket at the bottom of the motorcycle adapter on the HF tire changer. Time to break out the welder and fix that before continuing.

The install bar just would not work so I had to resort to tire irons. The tire was so stiff it required pulling on the irons so hard they were visibly bowing and I managed to pinch two tubes. (Grrrrrrr) I picked up a new tube (and a spare, just in case) and pondered how to get that SOB on. I figured that the only way to avoid pinching another tube was to figure out how get the install bar to work as that can’t pinch a tube. I already had a piece of plastic on the install end of the bar but the force was so high it was cutting through and making it harder to slide the bar around the rim. McMaster has plenty of choices for HDPE sheet so I got some 1/16” thick material and formed a piece hopefully thick enough to do the job.

Many others over the years have mentioned how much setting the tire in the sun to warm it up helps the tire stretch. The only problem is it’s in the 40’s here lately and not much sun so that’s not an option. Instead I found a cardboard box just big enough to hold the tire and placed an electric space heater inside set to the highest setting and put a kitchen thermometer probe inside to monitor the temperature. With a doubled-up sleeping bag on top the inside of the box would vary between 160 and 180 degrees as the heater cycled on and off.

I got everything all set up and let the tire heat soak for two hours and said a little prayer to the tire gods and dove-in. Between using copious amounts of Ru-Glyde tire lube, the “slidier”(???) mounting bar and the tire being noticeably easier to stretch I got it done but it was still fairly difficult.

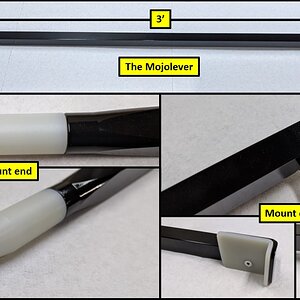

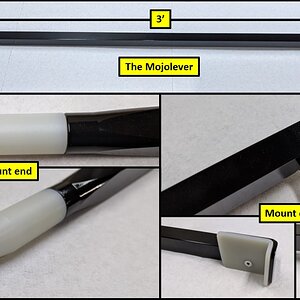

Either the shoulders on the rims are a bit bigger than usual, the tire bead diameter is a little smaller or both but I hope I don’t have to do one this tough again for a while. In any case it’s done and I can continue with reassembly. I keep hearing how much better the Mojolever works so I think after I’m done with this project that fabricating a similar unit will be my next project.