The case screws are M6's. I used to go 80 in/lbs on them but have reduced that to about 72 (6 ft/lbs). The clutch spring screws are also M6's, well at least the threaded part is, so you use M6 torque values for them (6 - 8 ft/lbs). Don't go 12 to 15, that would be way too much.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me XS 650...

- Thread starter Kevin Werner

- Start date

You could make up your own gasket. Mikey suggested an old cereal box and no doubt that would work. I buy gasket paper - usually a set with different thicknesses. The thickness isn't critical for this application. Trace around for the shape, or use Jim's grease method - take a look here:Does the gasket survive generally? I ask because springs arrived today and gasket might be 10-14 days behind.

https://www.xs650.com/threads/miss-november-xs2-tribute.55057/post-644441

I find a small pair of curved nail scissors is ideal to cut the gasket and Mrs hasn't noticed yet . . .

Leather punches are good to cut the screw holes.

That picture has a label; "stock image may not reflect actual item or quantity".How can they say that one fits ??

That's pretty common, it's expensive to take photos of thousands of commodity products. On the other hand not having a an accurate picture does cost sales. Cuz confidence you are getting the right part.......................

Thanks. The clutch only lets go when I am WFO at ~5200 rpm. With this BBK and jetting close to good, 5200rpm is pulling like a freight train, fun in small doses but I generally ride more relaxed and will make Ozarks regardless. If the gasket gets here I will replace the springs this weekend. Last thing I want to do is a late night wrench a thon with the incumbant errors, stripped threads, etc.n I can enjoy this motor all day long 3000-5000 rpm.If you tear the gasket when removing the side case, you can temporarily “patch” it up with some sealant. It may be a bear to remove when you get the proper replacement gasket but it may save your trip.

I have made gaskets with gasket paper and a ball peen hammer, works amazingly well. Bike is in a shop for tires now. No centerstand. Let them wrestle with it, I have granddaughter full time for the next couple of days.You could make up your own gasket. Mikey suggested an old cereal box and no doubt that would work. I buy gasket paper - usually a set with different thicknesses. The thickness isn't critical for this application. Trace around for the shape, or use Jim's grease method - take a look here:

https://www.xs650.com/threads/miss-november-xs2-tribute.55057/post-644441

I find a small pair of curved nail scissors is ideal to cut the gasket and Mrs hasn't noticed yet . . .

Leather punches are good to cut the screw holes.

I had a very, very wierd observation today. A day or two ago I screwed my clutch cable adjuster "in" to look at the ramp adjust nut. Time got in the way and I did nothing. A weather window, 37 degrees but no rain, opened up and I ran my bike to the dealer for new tires. Neutral was easy to find at every stop light.

Interesting. Can you elaborate on what you did. Not sure what the ramp adjust nut is. Thx.I had a very, very wierd observation today. A day or two ago I screwed my clutch cable adjuster "in" to look at the ramp adjust nut. Time got in the way and I did nothing. A weather window, 37 degrees but no rain, opened up and I ran my bike to the dealer for new tires. Neutral was easy to find at every stop light.

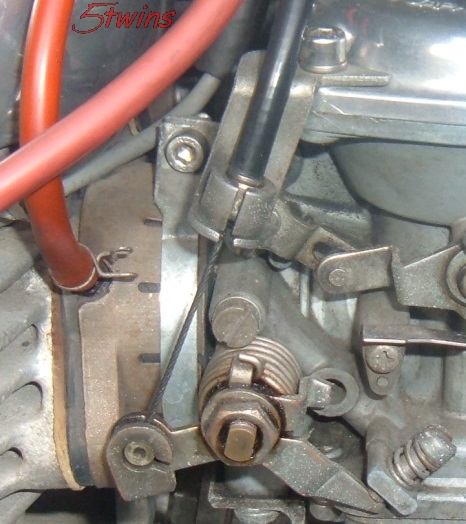

There is a silver dollar size button on the left side cover. Under that removable button is a lock nut on a screw adjuster. I was going to check that adjustment but did not get to it. Riding today, in a hurry to beat incoming rain,to a dealership 6 miles away I hit EVERY red light and found neutral easily each time. My curiosity is whether pushing the clutch rod "too far" causes problems.

Not in far enough means it doesn't fully disengage.... clutch drag... means it's hard to find neutral.My curiosity is whether pushing the clutch rod "too far" causes problems.

Adjusted "too" far in means the clutch never fully engages. That causes clutch slip under load.... like you're experiencing.

It's a balancing act. Not too much lever... not too little... just right.

As far as clutches go, the XS has very little extra travel to play with.

I know guys do it but I don't understand how they make that worm adjustment too tight. Once the freeplay is eliminated, the screw hits a hard stop. Turning it further will start to disengage the clutch, and you just can't do it with that little screw and a screwdriver. The only way I can figure it happening is if they set the adjustment tight when the motor is hot. Then when things cool down and the parts contract, your setting could end up being too tight.

I never got a chance to check the screw so I don't know how it is set. Something to look at when I get the bike back from the shop.

It's something you will need to get familiar with checking/adjusting.I never got a chance to check the screw so I don't know how it is set. Something to look at when I get the bike back from the shop.

Try this when the bike comes home.

https://www.xs650.com/threads/clutch-not-engaging.60295/page-3#post-705223

https://www.xs650.com/threads/clutch-not-engaging.60295/page-3#post-705223

So.... kudos to all you most helpful denizens of this XS650 foolishness. My son in Mankato MN who followed this a little, just acquired a 1980 XS650 and hopes to make the Smokies Rally with me Iin Sept.

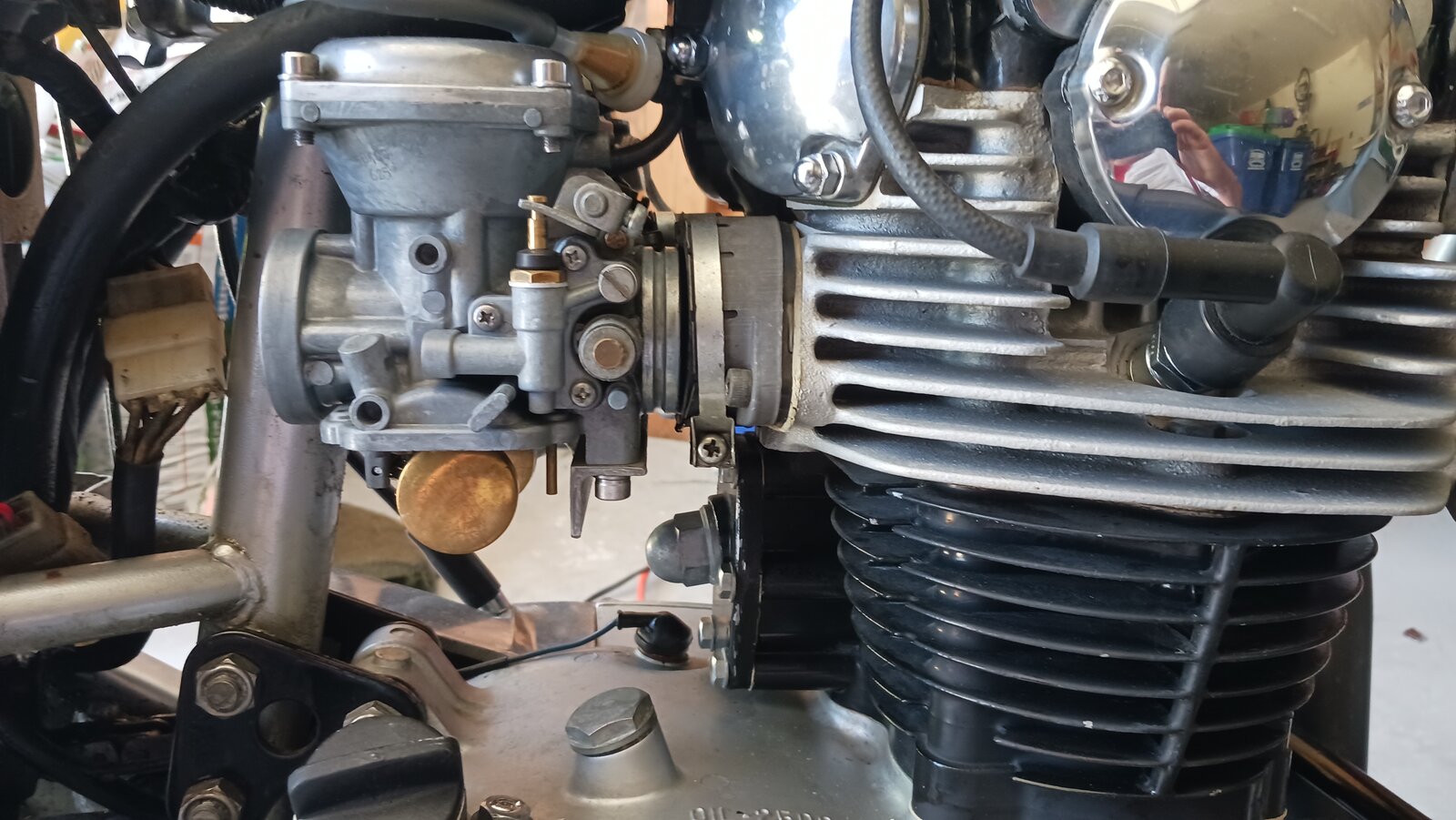

I am so stupid... Running on left cylinder only. Switched wires. Crossed wires. New plugs. Both plugs seemed to fire.

Ahhhhh, carburetor? Dropped float and checked float, needle goes up and down with slide etc. Reassembled it is still dead on the right...

Disassembled again and started to clean, then noticed....

HA HA.

Ahhhhh, carburetor? Dropped float and checked float, needle goes up and down with slide etc. Reassembled it is still dead on the right...

Disassembled again and started to clean, then noticed....

HA HA.

Missing float bowl?

WTF I'm looking Huh Where

Sometimes you just don't see it while your headed in a direction your sure must be right

Take the win !!

Sometimes you just don't see it while your headed in a direction your sure must be right

Take the win !!

Missing float bowl?

WTF I'm looking Huh Where

Sometimes you just don't see it while your headed in a direction your sure must be right

Take the win !!

Hidden in plain sight.

Congrats, you've now experienced one of the 650's "rights of passage", lol. Any time the bike backfires through the carbs, take a look at the manifolds to make sure it hasn't happened again. Mine did it to me once in a supermarket parking lot, lol. To avoid it in the future, make sure the timing is set very exact and tighten the manifold clamps fully, until the two clamp halves touch. Sometimes you can't do that if the original Phillips screw heads are buggered up at all so it's a good idea to switch to Allens. The original Phillips is an M5 x 25 but is longer than need be. You can use 20's, sometimes even 16's.

Similar threads

- Replies

- 785

- Views

- 81K

- Replies

- 20

- Views

- 5K

- Replies

- 7

- Views

- 5K

- Replies

- 33

- Views

- 6K