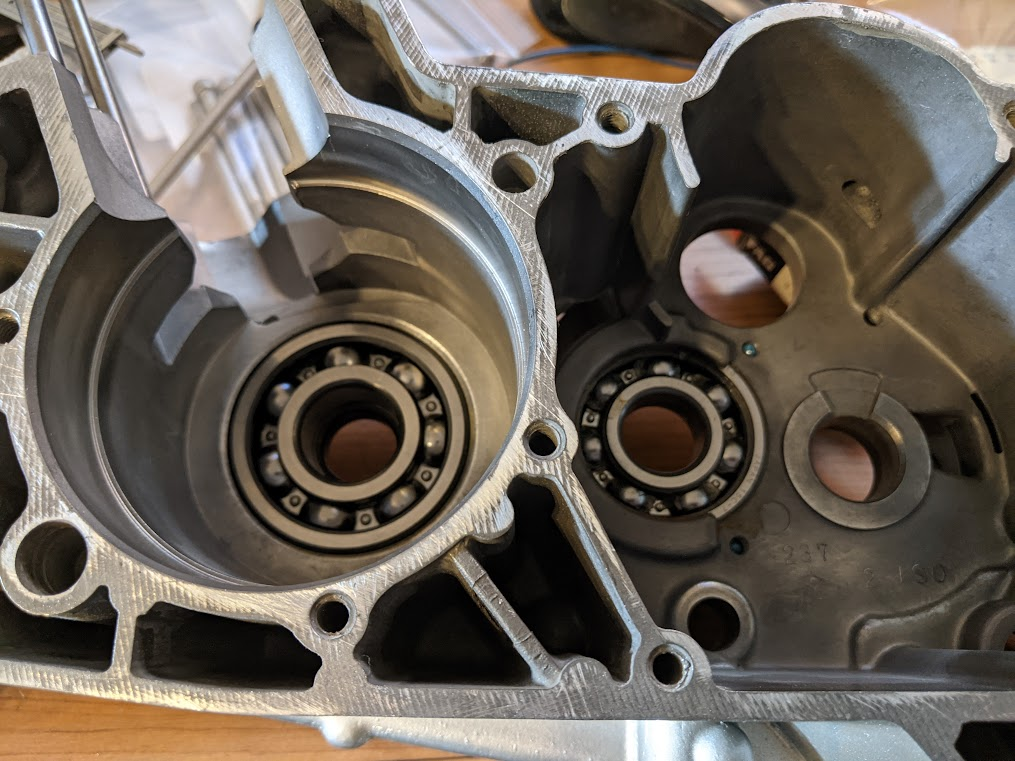

Pressed in the right side crank bearing and seal, and the right countershaft bearing.

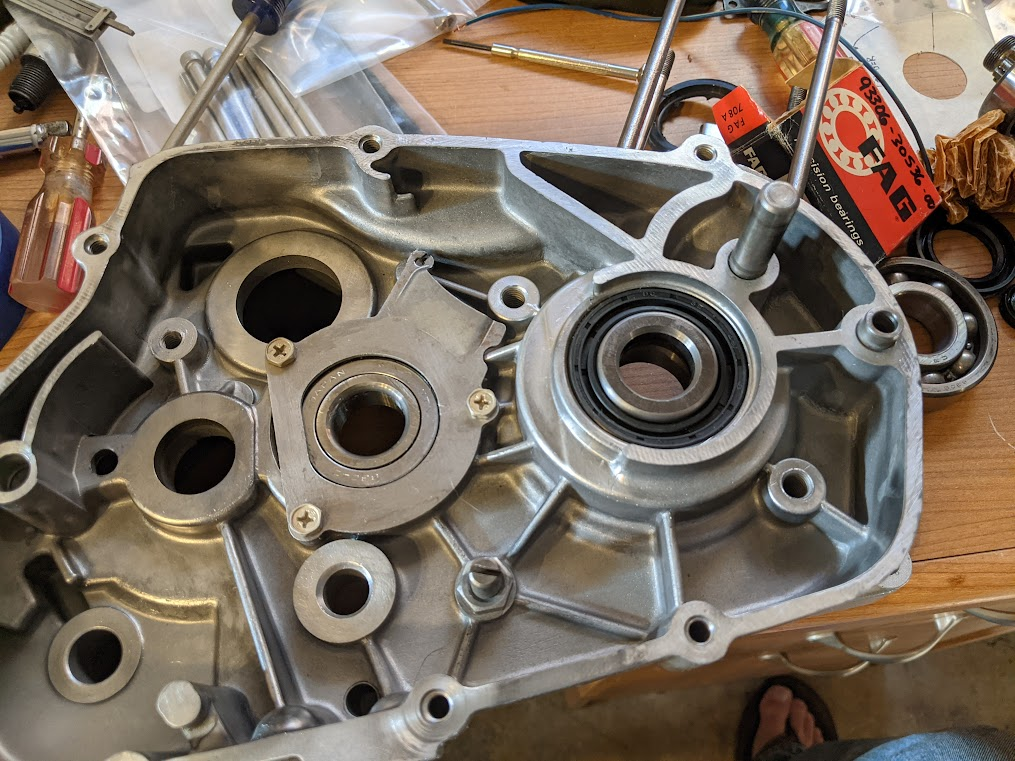

I trashed the 3 screws holding the "oil scoop" plate when I took it apart. Replaced them with 3 NAS 10-32 low profile screws, loctited in. Something to file away in the grey matter.... M5-.7 and 10-32 fasteners are interchangeable for all practical purposes.

Sometimes you have to get creative when you don't have a socket big enough for the bearing. End grain hardwood....

That's all the new bearings I've received so far. Back to waiting.

I trashed the 3 screws holding the "oil scoop" plate when I took it apart. Replaced them with 3 NAS 10-32 low profile screws, loctited in. Something to file away in the grey matter.... M5-.7 and 10-32 fasteners are interchangeable for all practical purposes.

Sometimes you have to get creative when you don't have a socket big enough for the bearing. End grain hardwood....

That's all the new bearings I've received so far. Back to waiting.

) onto a washer and TIG'd that into place.

) onto a washer and TIG'd that into place.