Got a bit of a dilemma here. First off, I've decided to replace both outer crank and all the tranny bearings. After cleaning 'em real good, some still have a bit of "notchiness" to 'em. The only one that feels about perfect is the ball one on the output shaft... so I'm gonna let that one slide. All others are gettin' replaced.

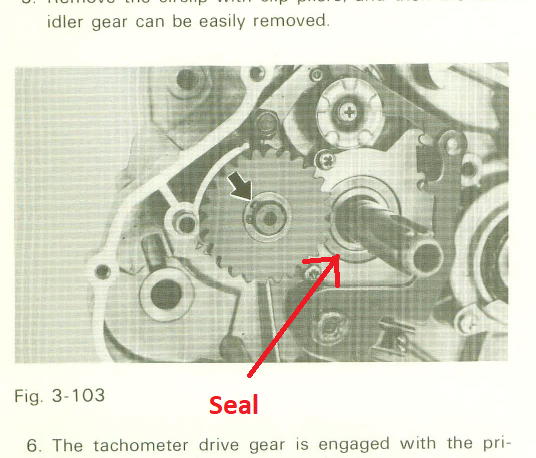

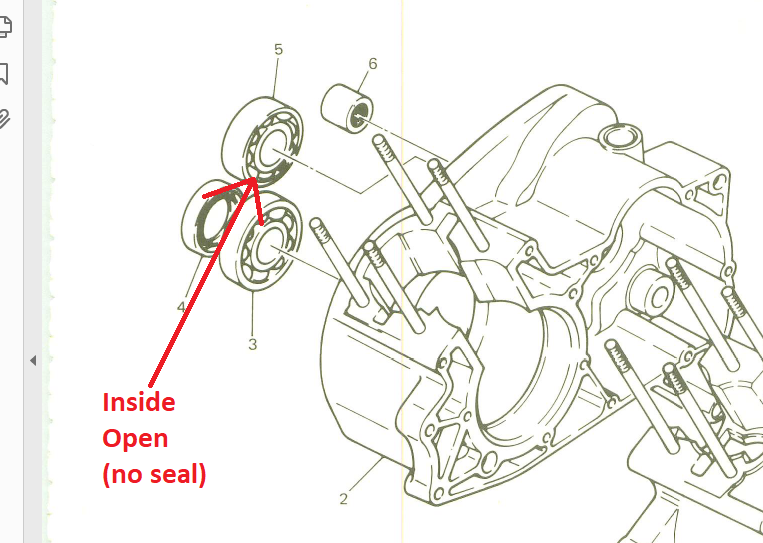

So anyway.... the ball on the right side of the countershaft, right next to the clutch basket is a little perplexing. The book calls for a 6304Z. It's a deep groove ball with shields (seals) on both sides. Except the pics in the book show only the outer seal installed, the inside (to the gears) is open.

And that's what I have, a 6304 with only the outer seal.

The dilemma? Well, there's also a plate on the outside of the seal with a "scoop" pressed into it. Almost a funnel type affair that looks like it's supposed to catch oil that's flung around and feed it to the bearing. Keep in mind that this is a "splash type" non-pressurized oil system. No pump in other words. Your typical 2-stroke tranny. So the scoop plate makes sense... except it's feeding the oil splash to a seal. Confused? Yeah, me too.

Here's the bearing and the splash plate.

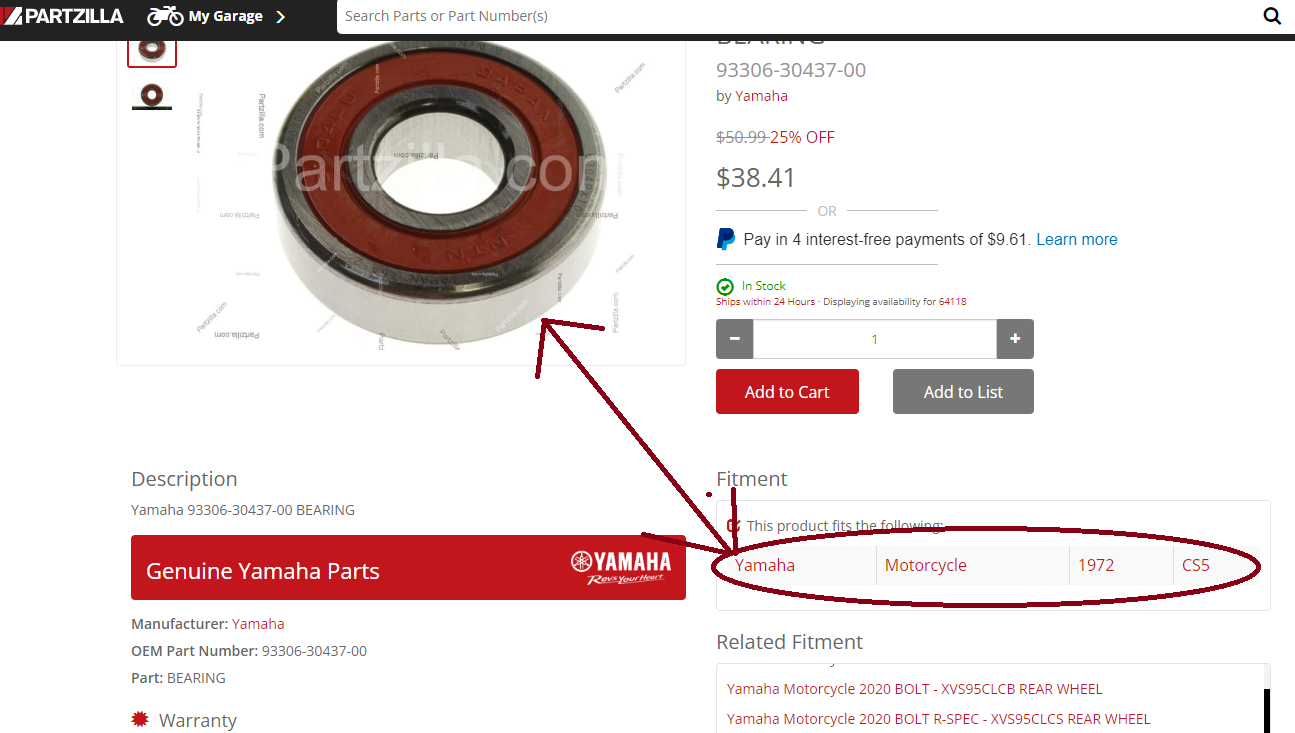

Now, here's the replacement bearing. OEM from Ebay at 15 bucks. It's what's called for in the IPC, except it's sealed on both sides.

Do I run it as is, with both sides sealed?

Remove the inner seal?

Remove both?

Wtf??

So anyway.... the ball on the right side of the countershaft, right next to the clutch basket is a little perplexing. The book calls for a 6304Z. It's a deep groove ball with shields (seals) on both sides. Except the pics in the book show only the outer seal installed, the inside (to the gears) is open.

And that's what I have, a 6304 with only the outer seal.

The dilemma? Well, there's also a plate on the outside of the seal with a "scoop" pressed into it. Almost a funnel type affair that looks like it's supposed to catch oil that's flung around and feed it to the bearing. Keep in mind that this is a "splash type" non-pressurized oil system. No pump in other words. Your typical 2-stroke tranny. So the scoop plate makes sense... except it's feeding the oil splash to a seal. Confused? Yeah, me too.

Here's the bearing and the splash plate.

Now, here's the replacement bearing. OEM from Ebay at 15 bucks. It's what's called for in the IPC, except it's sealed on both sides.

Do I run it as is, with both sides sealed?

Remove the inner seal?

Remove both?

Wtf??