HooliganCycles

XS650 Addict

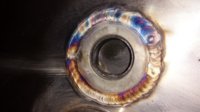

Hey we can't let this thread die, well I did a little welding today, not on the 650 but I needed to weld the crank pin on an HD twin can, and thought I would post a pic. I have been trying to work on my heat control a bit and I'm starting to get it under control