Perfect advice!

I might add; assemble the caliper with the piston pushed in just far enough to seal. Close bleeder, dribble brake fluid in though line port til filled then attach banjo and brake line. Now retract piston with a c-clamp, forces fluid through line and MC to reservoir removing air, done.

After reading some great threads on rear disc brake problems I removed the entire rear brake system and hung the m/c and reservoir up high above the work bench then removed the piston from the caliper, blew it out and coated the bore, seal and piston with red rubber grease.Yesterday I realized the rear brake pads were only contacting the disc rotor with the top half of the brake pads, I had the same issue last year and replaced the disc rotor and caliper hanger and the brake seemed to work well.

I removed the caliper and by pumping the brake pedal could see the piston push out then retract when I let the pedal return to it's stop.

I used air pressure to pump out the piston and blew out the entire system and half filled the piston bore with clean brake fluid, installed the piston and tried to push the piston back in using a f clamp. The only way to get the piston to push in was by opening the bleeder which doesn't seem right I thought it would push the fluid back into the master cylinder reservoir?.

I have tried bleeding the whole system but after the first squirt I'm not getting any fluid.

I filled the caliper through the banjo bolt hole and the bleeder hole after installing the piston and even tried a hose on the bleeder to a large plastic syringe and cracked the bleeder and try and suck the fluid through but get nothing.

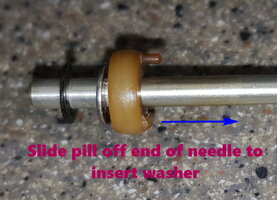

Can't see any leaks and fitted new copper washers and thread tape on the threads.

Guess I should have left it alone,at least they worked?

I then installed the piston so that it was just sealed with the bleed screw closed,then using the banjo bolt hole filled the caliper with brake fluid and attached the brake line.

With the caliper in the vice it was easy to push the piston in by hand using a small tyre lever in the gap between the piston and caliper, doing this slowly I could watch the air bubbles in the resivoir then put the lid on and fitted the entire system back on the bike starting with the master cylinder then the caliper.

Last step was to bleed the caliper so with the hose on the bleeder screw I worked the brake pedal a few times then holding it down opened the bleed screw and it was steady fluid with no bubbles at all.

Once again the solution was on this great site, I found the tip on here about using red rubber grease instead of brake fluid to lube seal everything and I've never seen a piston so easy to push in, and great tip from gggGary about just sealing the piston and filling the caliper via the hole, then with the hose on push the piston in,worked great.