I don't think it will make any difference if you put the uprights inside the base. Just compensate by making your base wider. However you build it, you need to end up with the same spacing between the uprights or it won't fit on the motor. You also want to end up with the same difference in hole heights between the front and rear uprights or the motor won't sit level in the stand.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cleaner Engine Stand Plans

- Thread starter alfredo

- Start date

5twins, I can picture how that would work now, thanks.

Leo

Leo

TwoJugs

Excess XS

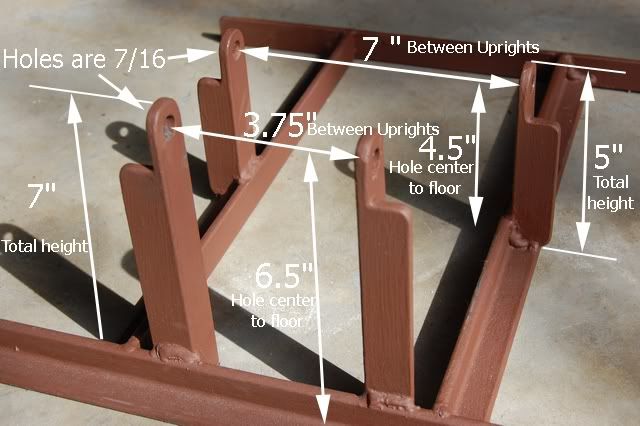

I made these. The first one was tacked together with a motor case to get dimensions. The second was made with measurements from the first. Someone wrote and said the dimensions were wrong but it works for me? A little taller and wider then others. Stable and allows bottom access. Fits real nice on a Harbor Frieght $8.99 dolley.

David M

XS650 Enthusiast

I haven't seen anyone mention the weight of the engine. Any well informed estimates out there ?

I picked up an engine and carried it to my van yesterday and carried it back out today.I haven't seen anyone mention the weight of the engine. Any well informed estimates out there ?

120 pounds?

160 pounds according to a thread on the old 650 site. Guess I am stronger than I thought.

David M

XS650 Enthusiast

Thanks gggGary.

And, another engine stand :

http://www.tcbroschoppers.com/international/index.php?main_page=product_info&cPath=17&products_id=1

And, another engine stand :

http://www.tcbroschoppers.com/international/index.php?main_page=product_info&cPath=17&products_id=1

scarface6477

XS650 Enthusiast

hey guys anyone using any of these engine plans with an older motor? i thought i read somewhere the motor mounts are a little different on the older xs's. i have a 72. but cant get measurement s at this time and will be welding a stand up tommorrow.

Thanks!

Thanks!

I have one on a '70-'71 motor. 2nd style using 1st set of dimensions. Up/down and front to rear dimensions are wrong on 2nd plan. 6.5" is too much front to rear and 2" up/down makes the engine sit unlevel.

Tomterrific

XS650 Junkie

Bed frames are the best place to get angle iron. I find mine in the trash. There are so many metal scrapers looking for metal to fill their pick-ups the trash isn't as good of supply as it was in the past. People throw out bedframes because allot of mattress companies sell the set with a frame. Pick up the frame as soon as you see one. That's some nice steel for projects!

Tom Graham

Tom Graham

angus67

Welder's penetrate deeper!!

um....alfredo is done with his bike. its on 650chopper.com.

+1 on bed frames! I snag em whenever I see em. I used to have a secret metal yard I could pick through and take what I wanted but the last time I went there a scrapper had picked it clean.

I use 3/8" threaded rod that I cut to length I needed. It's a little bit smaller than the hole and it works fine.

racerdave

^ Gone not forgotten ^

I found plans to build an engine stand, but they were hardly legible. I redrew them and changed two things; 1) added an inch to the height for clearance with the starter still installed and 2) changed the hole size to a proper one. Both suggestions came from this thread.

I am posting a small JPG and a link to the PDF version for clear printing. Let me know if it needs adjustment. Cheers guys!

download it here

It seems some stands do and some don't have enough clearance for the starter. Does this one work well with the starter?

I like the one that allows you to spin the motor upside down to get to the bottom end. I have seen lots of different designs on ebay and they all were the type that just allows top end work. I haven't yet seen one on ebay that allows for bottom end work. Not being a welder myself I was hoping to buy one.

jefft

jefft

Yes, Alfredo's version will allow starter clearance. Here's a link to the original plans. As you can see, the uprights are about an inch shorter. If you look at the pics, you'll see the guy needed to cut a "V" notch in the right side rail for starter clearance. Make the uprights longer and you don't need to do that .....

http://www.650motorcycles.com/XSstand.html

Here's mine and as you can see, the starter clears just fine. I use it on an old A/V stand I pulled out of a dumpster at work (amazing the good things they throw out, lol). I also added an outrigger to the side to hold the cam chain up .....

http://www.650motorcycles.com/XSstand.html

Here's mine and as you can see, the starter clears just fine. I use it on an old A/V stand I pulled out of a dumpster at work (amazing the good things they throw out, lol). I also added an outrigger to the side to hold the cam chain up .....

Last edited:

Similar threads

- Replies

- 785

- Views

- 81K

- Replies

- 20

- Views

- 3K